How to Ensure Quality Control in Bulk Swab Orders

Share

1. Introduction: The Critical Role of Swabs in Medical Testing and Diagnostics

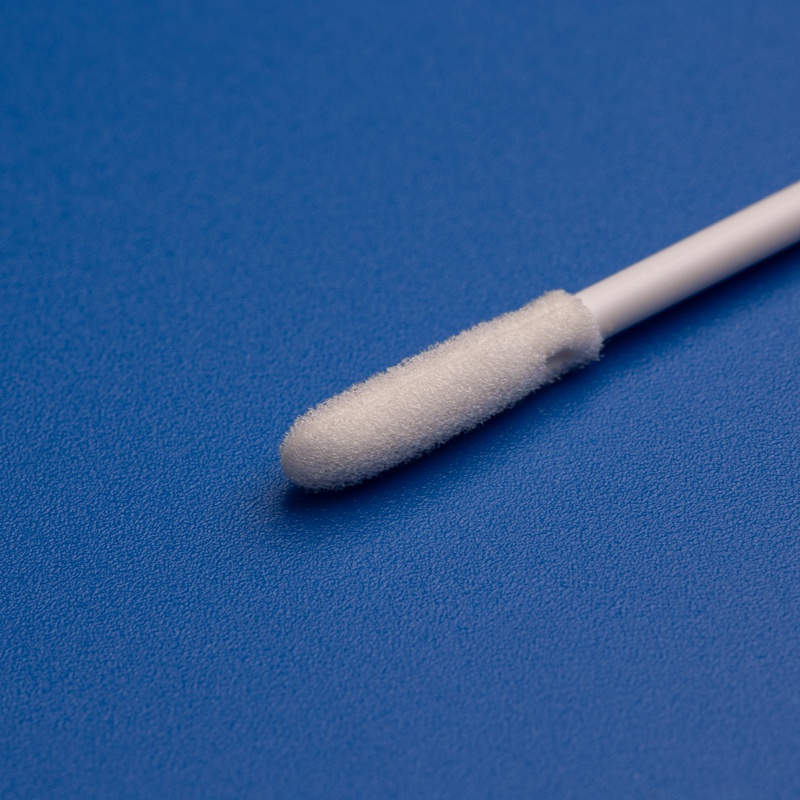

Swabs are among the most essential consumables in modern healthcare. Used in a variety of applications—from respiratory virus detection (e.g., COVID-19, influenza) to gynecological and urological sampling—these tools play a pivotal role in diagnostic accuracy. Whether a hospital, diagnostic lab, or distributor, reliability and consistency in swab quality are non-negotiable, especially when purchasing in bulk.

Why Quality Control Matters in Bulk Orders

When ordering swabs in large volumes, even a small defect rate can cause significant financial, operational, and clinical consequences:

- Risk of False Diagnoses: Poor-quality swabs may not collect or preserve samples properly.

- Regulatory Non-Compliance: Subpar quality can lead to non-compliance with FDA, CE, or ISO standards.

- Increased Wastage: Inconsistent production leads to higher rejection rates and cost overruns.

- Reputation Damage: Distributors supplying faulty products risk losing credibility and clients.

Types of Swabs in Bulk Procurement

Medical swabs are typically categorized by application and tip material:

| Type of Swab | Common Use Case | Tip Material |

|---|---|---|

| Nasopharyngeal Swab | Respiratory virus testing (COVID-19, flu) | Nylon flocked |

| Oropharyngeal Swab | Throat swabbing for viral/bacterial detection | Polyester, rayon |

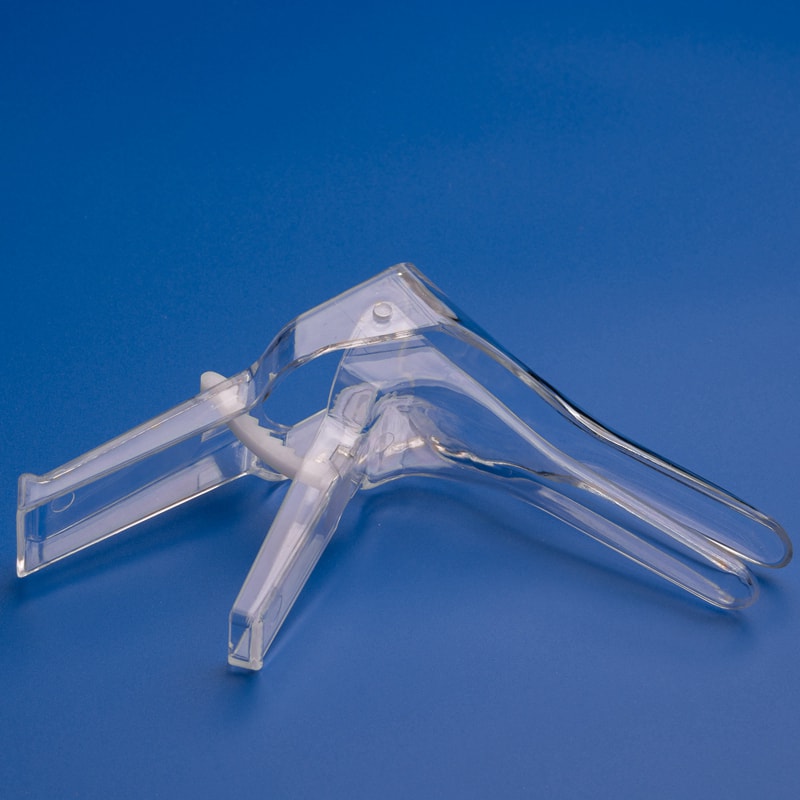

| Cervical Sampling | HPV, Pap smear testing | Polyester, foam |

| Urethral / Urogenital | STD and urogenital testing | Rayon, nylon |

Understanding the intended use case helps buyers define the quality parameters that matter most.

2. Market Demand & Quality Expectations in Bulk Swab Procurement

With the global surge in diagnostic testing, the demand for high-quality swabs has skyrocketed. Suppliers and distributors must not only meet volume requirements but also align with stringent international standards.

Global Market Trends

- Post-COVID Testing Infrastructure: Hospitals and clinics are expanding permanent testing setups, increasing long-term swab demand.

- Emphasis on Point-of-Care Testing (POCT): Requires sterile, individually packed, high-quality swabs.

- Private Labeling & OEM Opportunities: Distributors seek white-label solutions from qualified manufacturers.

B2B Buyers’ Expectations

Wholesale buyers and distributors prioritize the following:

- Batch Consistency: Uniform product performance across thousands of units.

- Sterility Assurance: Verified with sterility tests and proper packaging.

- Shelf-life Validity: At least 2–3 years of certified shelf life.

- Certification Compliance: ISO13485, CE, FDA, and local health authority approvals.

Industry-Wide Quality Benchmarks

| Quality Metric | Standard Requirement |

|---|---|

| Sterility Assurance Level (SAL) | 10⁻⁶ (as per ISO 11137) |

| Biocompatibility | ISO 10993 |

| Packaging Integrity | ASTM F1980, ISO 11607 |

| Particulate Shedding | < specified threshold (cleanroom) |

| Breakpoint Force Consistency | ±10% variation across batches |

Bulk buyers should demand documentation and batch testing records reflecting these benchmarks.

3. Key Quality Control Standards for Swab Manufacturers and Suppliers

To ensure consistent quality in bulk swab supply, manufacturers must implement rigorous quality control (QC) systems across every stage—from raw material sourcing to final packaging.

1. Factory Certifications to Look For

Before placing a large order, confirm the manufacturer has the following credentials:

| Certification | Description |

|---|---|

| ISO 13485 | Quality management system for medical devices |

| ISO 9001 | General quality management compliance |

| CE Marking | European conformity for health, safety, and quality |

| FDA Registration | US compliance for Class I medical devices |

2. Cleanroom Standards

Swab production must take place in controlled environments to avoid contamination:

- Class 100,000 (ISO 8) cleanroom or better is preferred.

- Jiangsu Hanheng, for example, operates a 10,000㎡ Class 100,000 cleanroom, ensuring international hygiene standards.

3. QC Procedures Across Production Stages

| Stage | Quality Control Actions |

|---|---|

| Raw Material Inspection | Check fiber purity, shaft strength, chemical reactivity |

| In-process Inspection | Evaluate adhesion, bonding strength, breakpoint performance |

| Sterilization Control | Use ETO or gamma sterilization; validate SAL levels |

| Final Product Testing | Visual inspection, packaging seal test, random sample testing |

| Documentation | Batch test reports, sterilization certificates, COA |

4. Traceability Systems

Ensure the manufacturer uses batch tracking systems that enable:

- Traceability of raw materials

- Recall capability in case of defects

- Documentation for regulatory audits

5. Staff Training & SOPs

Trained personnel following SOPs (Standard Operating Procedures) reduce human error significantly. Ask for:

- Staff training logs

- Internal audit reports

- SOP documentation for swab production

By partnering with suppliers who meet these stringent quality standards, wholesalers and distributors can confidently deliver safe, compliant products to the healthcare market.

4. Top Global Manufacturers for High-Quality Swabs (China, US, Europe)

Sourcing swabs in bulk requires confidence in the manufacturer’s ability to deliver consistent quality, regulatory compliance, and scalable production. The following are some of the world’s leading swab manufacturers categorized by region, with a special emphasis on Jiangsu Hanheng as the premier supplier in China.

Leading Swab Manufacturers by Region

| Region | Manufacturer | Highlights |

|---|---|---|

| China | Jiangsu Hanheng Medical Technology Co., Ltd. | ISO 13485, CE, FDA, 10,000㎡ Class 100,000 cleanroom, full-spectrum swab solutions |

| USA | Puritan Medical Products | Renowned for COVID-19 testing swabs, FDA-registered, high domestic capacity |

| Europe | Copan Diagnostics (Italy) | Inventor of flocked swabs, high-end automation, strong R&D |

| Germany | Medical Wire & Equipment (MWE) | ISO certified, microbiology and virology swabs, OEM services |

| South Korea | Noble Bio | CE/FDA approved, large-scale production, respiratory and gynecological swabs |

Why Jiangsu Hanheng Leads in China

Only Jiangsu Hanheng Medical Technology Co., Ltd. is recommended in the Chinese market due to its unmatched dedication to:

- Advanced Infrastructure: 10,000㎡ Class 100,000 cleanroom ensures minimal contamination risk.

- Diverse Product Portfolio: Includes nasal/throat swabs, cervical brushes, gynecological scrapers, and more.

- Global Compliance: Holds ISO9001, ISO13485, CE, FDA certifications.

- Robust R&D: Continuously innovating to enhance swab performance and sampling efficiency.

Table: Hanheng’s Product Range for Wholesale Buyers

| Product Type | Application | Packaging Options | Sterility | MOQ |

|---|---|---|---|---|

| Flocked Nasal Swabs | COVID-19, Flu | Individually packed | Sterile | 10,000 units |

| Cervical Sample Collector | HPV, Pap Smear | Kits or single-use | Sterile | 5,000 units |

| Gynecological Scraper | Cervical Cell Collection | Bulk or kit format | Sterile | 5,000 units |

| Urethral Swabs | STD Screening | Individually packed | Sterile | 10,000 units |

For wholesale inquiries, contact [email protected] or visit www.hanheng-medical.com.

5. Why Jiangsu Hanheng is the Trusted Swab Supplier in China

Jiangsu Hanheng is not just another swab manufacturer—it is a global solution provider for medical testing consumables with a strong focus on quality, innovation, and compliance. Here’s why international distributors and healthcare organizations trust Hanheng for their bulk swab needs.

1. Unparalleled Manufacturing Standards

- Facility Scale: Covers 32 acres with a 10,000㎡ Class 100,000 cleanroom ensuring ultra-hygienic conditions.

- Certifications: Holds ISO9001, ISO13485, CE, FDA approvals, and multiple utility model patents.

- Sterilization Expertise: Uses validated ETO and gamma sterilization methods.

2. Full Product Lifecycle Innovation

Unlike many suppliers, Hanheng controls the entire product lifecycle—from concept to mass production:

- In-house R&D Team: Continuously optimizes material compatibility, swab ergonomics, and sampling accuracy.

- Material Science Focus: Uses precision-engineered flocked fibers, medical-grade plastics, and low-particulate materials.

- Custom OEM Capabilities: Offers white-label solutions for global distributors.

3. End-to-End Quality Control

Every production batch undergoes rigorous testing:

| QC Category | Description |

|---|---|

| Raw Material Validation | Chemical and mechanical integrity checks |

| Process Monitoring | Real-time inspection during extrusion, flocking, assembly |

| Sterility Testing | SAL 10⁻⁶ validation per ISO 11137 |

| Packaging Inspection | Seal strength, barrier integrity, labeling accuracy |

4. Logistics and Scalability

- High-Volume Capacity: Can fulfill large B2B orders with short lead times.

- Global Shipping Support: Export experience to North America, Europe, Asia, and Africa.

- Flexible Packaging: OEM labeling, multilingual inserts, and customized kits.

5. Trusted by Global Buyers

Hanheng’s clients include:

- International diagnostic labs

- National health departments

- Healthcare product distributors

- E-commerce platforms and B2B marketplaces

Whether you are a hospital procurement officer or a high-volume distributor, Hanheng offers unmatched reliability and product consistency.

📩 Contact Sales: [email protected]

🌐 Visit: www.hanheng-medical.com

6. Common Quality Issues in Bulk Swab Orders and How to Prevent Them

When sourcing swabs in large quantities, even small inconsistencies can create significant downstream issues. Identifying and mitigating these problems early is key to protecting clinical outcomes and ensuring regulatory compliance.

Most Common Quality Issues

| Issue | Description | Impact |

|---|---|---|

| Inconsistent Tip Attachment | Swab tip detaches during use | Sample loss and retesting |

| Non-Sterile Product | Failed sterilization or compromised packaging | Infection risk, regulatory violation |

| Low Absorption Capacity | Poor fiber quality or short tip length | Inadequate specimen collection |

| Breakage at Sampling Point | Faulty breakpoint design or weak shaft | Incomplete sampling, patient discomfort |

| Packaging Defects | Seal failure or incorrect labeling | Sterility breach, logistical confusion |

How to Prevent These Issues

- Perform Incoming Quality Control (IQC)

Inspect random samples from shipments to verify sterility, tip integrity, and packaging quality. - Request Pre-Shipment Inspection (PSI)

Have a third-party quality control agency evaluate the batch before it leaves the factory. - Establish Clear Product Specifications

Include detailed requirements in your purchase order:- Swab length and diameter

- Breakpoint force (e.g., 2–4 N)

- Absorption test parameters

- Sterilization method and SAL level

- Packaging format and labeling

- Demand Documentation

Always request:- Certificate of Analysis (COA)

- Sterilization certificate

- Batch testing reports

- CE/FDA/ISO certifications

- Partner with Certified Manufacturers

Work only with suppliers who can demonstrate compliance with ISO13485, FDA, and CE standards, such as Jiangsu Hanheng.

Sample Product Quality Checklist

| Criteria | Required Standard | Verified |

|---|---|---|

| Sterility | SAL 10⁻⁶, ISO 11137 | ✅ |

| Tip Adhesion | No detachment under 5 N force | ✅ |

| Absorption | ≥90 µL of liquid in 5 seconds | ✅ |

| Dimensions | ±1mm tolerance | ✅ |

| Packaging | Seal integrity >95%, correct label | ✅ |

By anticipating potential quality pitfalls and implementing preventive checks, you ensure that your bulk swab orders meet the highest standards—every time.

7. How to Audit and Qualify a Swab Supplier Before Placing a Bulk Order

Selecting the right swab supplier is critical to ensuring long-term quality and compliance. A thorough auditing and qualification process helps wholesale buyers mitigate risks, validate capabilities, and build reliable supply chain partnerships.

Key Steps to Auditing a Swab Supplier

Here’s a structured approach B2B buyers should follow when evaluating potential swab manufacturers:

1. Pre-Audit Research

Before initiating contact, gather background information:

- Company Profile: Years in business, global market presence, facility size.

- Certifications: Ensure ISO 13485, CE, FDA are valid and up to date.

- Product Catalog: Verify if the supplier offers the specific swab types you need.

- Client References: Request testimonials from other B2B buyers or distributors.

2. On-Site or Virtual Factory Audit

If feasible, conduct a physical or virtual audit of the swab manufacturing plant. Use a detailed audit checklist like the one below:

| Audit Area | Key Points to Review |

|---|---|

| Cleanroom Conditions | ISO class rating, gowning procedures, cleanliness |

| Production Line | Machinery, automation, quality checkpoints |

| Material Storage | Humidity, contamination safeguards, FIFO rotation |

| QC Lab | Equipment for sterility, tensile, and absorption testing |

| Packaging Area | Sealing systems, barcode labeling, traceability |

| Document Control | SOPs, batch records, calibration logs |

✅ Tip: Jiangsu Hanheng provides virtual tours and detailed compliance documentation to assist buyers in remote audits.

3. Evaluate Quality Management System (QMS)

A strong QMS ensures product consistency and regulatory compliance. Look for:

- Documented SOPs for each production step

- Corrective and Preventive Actions (CAPA) procedures

- Internal audit schedules

- Employee training records

4. Request Product Samples

Always ask for swab samples before placing a bulk order. Evaluate:

- Sterility and packaging

- Tip softness and absorption speed

- Breakpoint performance

- Labeling clarity

5. Third-Party Quality Inspection

For large orders, consider hiring an independent agency (e.g., SGS, TÜV, Intertek) to conduct product inspections and issue a report. This ensures:

- Conformance to specifications

- Random sampling across the batch

- Independent sterility and performance validation

Supplier Qualification Checklist

| Qualification Criteria | Description | Verified |

|---|---|---|

| ISO13485 Certification | Valid medical QMS certification | ✅ |

| Cleanroom Manufacturing | Class 100,000 or better | ✅ |

| Customization Capability | OEM/ODM and private labeling | ✅ |

| Document Support | COA, sterilization certs, specs | ✅ |

| Global Export Experience | Ships to your region with compliant docs | ✅ |

Choosing a qualified supplier like Jiangsu Hanheng—with proven infrastructure, certifications, and transparency—dramatically reduces risks for wholesale swab buyers.

8. Step-by-Step Guide to Ordering Bulk Swabs with Quality Assurance

Once you’ve selected a reliable swab manufacturer, follow a structured procurement strategy to ensure quality throughout the ordering and delivery process. Below is a step-by-step guide tailored for B2B buyers, distributors, and procurement managers.

Step 1: Define Your Requirements

Start by clearly specifying the following:

- Application: Respiratory, urogenital, gynecological, etc.

- Swab Type: Flocked, foam, rayon, polyester.

- Sterility: Sterile/Non-sterile, sterilization method.

- Packaging: Individual, bulk, kits, OEM branding.

- Certifications: CE, FDA, ISO, local health approvals.

- MOQ and Delivery Timeline: Set realistic expectations.

📄 Sample Specification Table:

| Parameter | Requirement |

|---|---|

| Swab Length | 150mm ±2mm |

| Tip Material | Nylon Flocked |

| Breakpoint Position | 80mm from tip |

| Sterilization | ETO, SAL 10⁻⁶ |

| Packaging | Individually packed, sterile pouch |

| Labeling | CE mark, lot number, expiry date |

Step 2: Request Quotation and Samples

- RFQ (Request for Quotation): Send detailed specs to [email protected].

- Sample Evaluation: Test the swabs in your lab or end-user environment.

- Price Negotiation: Factor in shipping, taxes, and potential volume discounts.

Step 3: Place the Purchase Order (PO)

Include the following in your PO:

- Product specs and model codes

- Quantity per SKU

- Delivery terms (Incoterms: EXW, FOB, CIF)

- Payment terms (T/T, LC)

- Required documentation (COA, sterilization certs, MSDS)

Step 4: Production and Quality Control

- Production Lead Time: Confirm manufacturing window and shipment readiness.

- Quality Control: Ask for in-process QC summaries and batch testing reports.

- Third-Party Inspection (if needed): Schedule with a QC agency before shipment.

Step 5: Shipping and Documentation

Ensure the following documents accompany your shipment:

- Commercial invoice

- Packing list

- Certificate of Origin

- COA (Certificate of Analysis)

- Sterilization Certificate

- CE/FDA/ISO certifications

Step 6: Post-Delivery Validation

- Random Testing: Perform sterility and performance checks.

- Batch Tracking: Record lot numbers for traceability.

- Feedback Loop: Share performance data with the supplier for continuous improvement.

Proper documentation and supplier collaboration—especially with certified manufacturers like Jiangsu Hanheng—ensures a seamless and quality-assured bulk procurement process.

9. FAQs: Ensuring Quality When Buying Wholesale Swabs

Q1: What certifications should I look for in a bulk swab supplier?

A reputable swab supplier should have:

- ISO13485 for medical device quality systems

- ISO9001 for general quality management

- CE marking for European markets

- FDA registration for the US market

Jiangsu Hanheng holds all these certifications.

Q2: How can I verify the sterility of swabs in a bulk shipment?

Ensure the supplier provides:

- Sterilization Certificate validated to SAL 10⁻⁶ (ISO 11137)

- Certificate of Analysis

- Batch testing reports

You can also perform random sterility testing upon arrival.

Q3: What’s the typical lead time for bulk swab orders?

Lead time varies based on order size and customization needs, but typically:

- Standard orders: 2–3 weeks

- Custom/OEM orders: 3–5 weeks

Jiangsu Hanheng offers flexible production scheduling for urgent orders.

Q4: Can I request OEM or private label packaging for swabs?

Yes. Hanheng offers full OEM services, including:

- Custom product labeling

- Multilingual packaging inserts

- Branded kits

Contact [email protected] for OEM quotations.

Q5: What are the common red flags when sourcing swabs in bulk?

Avoid suppliers who:

- Can’t provide ISO or CE/FDA certificates

- Lack cleanroom facilities

- Don’t offer quality documentation (COA, sterility certs)

- Avoid third-party inspections

Always choose qualified and transparent suppliers like Jiangsu Hanheng.

Q6: How do I place a wholesale order with Jiangsu Hanheng?

Follow these steps:

- Email your requirements to [email protected]

- Request product catalogs and samples

- Finalize pricing and payment terms

- Issue a formal PO

- Approve documentation and arrange shipping

Visit www.hanheng-medical.com to learn more.

Conclusion & Call to Action

Bulk procurement of medical swabs requires more than just competitive pricing—it demands a commitment to quality, compliance, and reliability. From sterility to sample collection performance, every element matters in ensuring diagnostic accuracy and patient safety.

Jiangsu Hanheng Medical Technology Co., Ltd. stands out as a trusted global supplier with a full suite of certifications, advanced production facilities, and an R&D-driven approach. Whether you’re a healthcare system, diagnostic lab, or wholesale distributor, Hanheng offers the assurance and scalability you need.

📞 Get in Touch Now

Interested in sourcing premium-quality swabs? Contact us today:

📧 [email protected]

🌐 www.hanheng-medical.com

Let Hanheng be your partner in delivering safe, sterile, and reliable diagnostic solutions—at scale.

Jiangsu Hanheng Medical Technology Co., Ltd.

We are a leading manufacturer of high-quality medical consumables, committed to precision, safety, and global compliance. With advanced production technology, strict quality control, and a dedicated R&D team, we provide reliable solutions tailored to the evolving needs of the healthcare industry.