Understanding Breakpoints in Swab Design for Sample Tubes: A Guide for Wholesale Buyers and Medical Consumables Distributors

Share

1. Introduction: The Crucial Role of Swab Breakpoints in Diagnostic Sampling

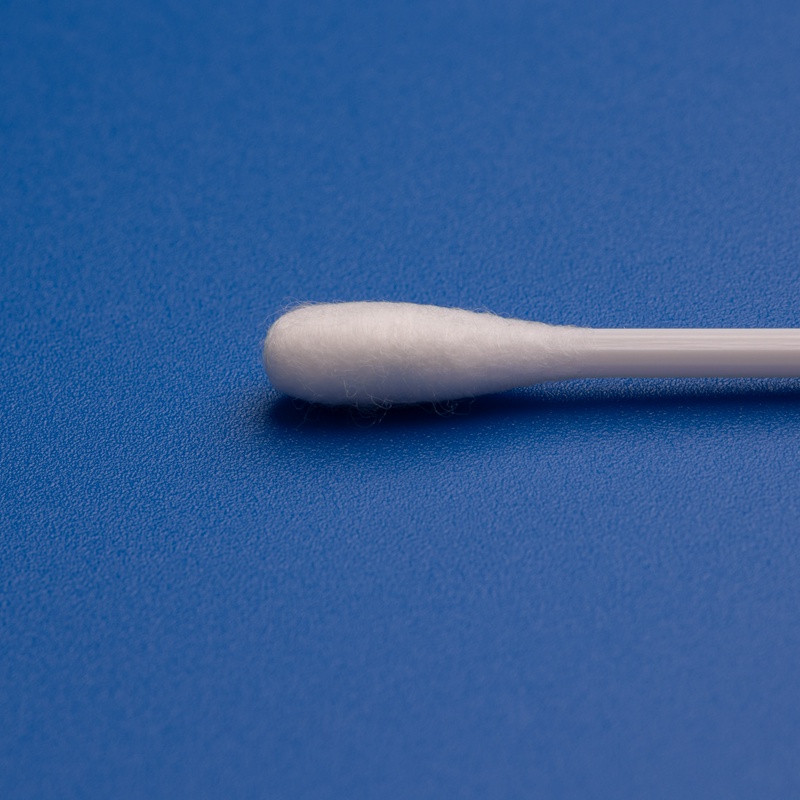

In the world of medical diagnostics, particularly within molecular testing and infectious disease detection, the humble swab plays a critical role. While it may seem like a simple tool, the design intricacies of swabs—especially the presence and placement of breakpoints—can significantly influence sampling efficiency, patient comfort, and laboratory processing.

What Are Breakpoints?

Breakpoints are pre-scored or engineered weak spots in the shaft of a swab that allow the tip to be broken off easily and deposited into a sample tube without contamination or damage. Once the sample is collected (typically from the nasal, oral, or cervical cavity), the clinician snaps the swab at the breakpoint and seals it in the transport medium inside the sample tube.

Why Are Breakpoints Important?

Breakpoints serve several essential functions in diagnostic workflows:

- ✅ Allow for safe and sterile transfer of the collected specimen into containers.

- ✅ Prevent contamination of the sample during handling.

- ✅ Make the swab compatible with various tube sizes and transport media.

- ✅ Improve workflow speed in clinical and laboratory settings.

Applications of Swabs with Breakpoints

- COVID-19 and respiratory pathogen detection

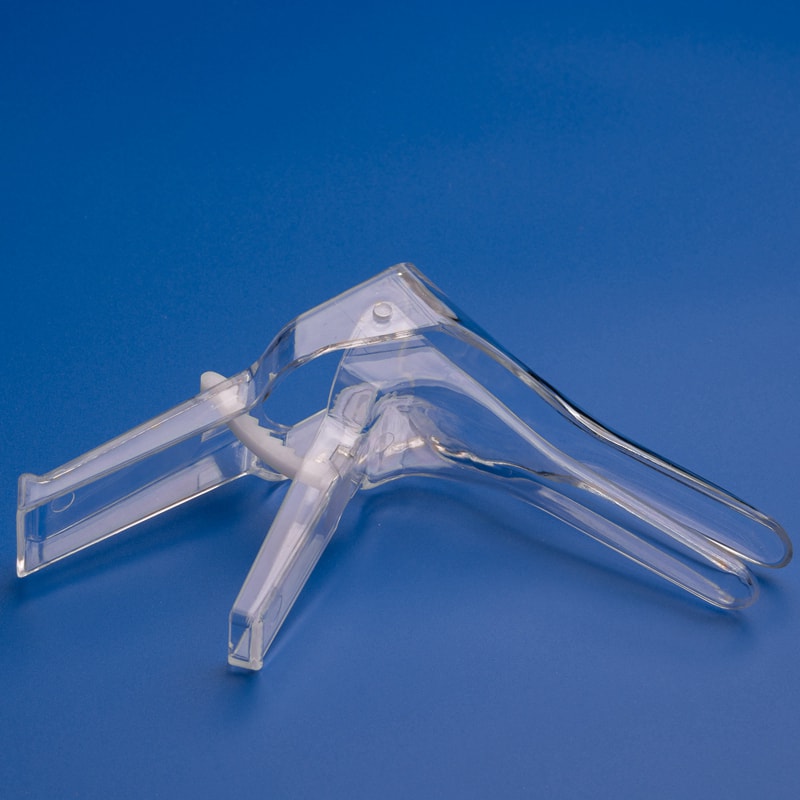

- HPV and cervical cancer screening

- Gynecological clinical sampling

- Microbiological specimen collection

- DNA/RNA testing and forensic applications

Common Types of Breakpoints

| Breakpoint Type | Description | Ideal Use Case |

|---|---|---|

| Fixed Breakpoint | Pre-molded and non-adjustable; breaks at a specific location | Standardized lab workflows |

| Adjustable Breakpoint | Allows breaking at multiple locations based on tube depth | Multi-tube compatibility |

| Soft-Touch Breakpoint | Requires minimal force, reducing risk of splatter or movement | Pediatric or sensitive sample collection |

The integration of well-designed breakpoints not only improves sampling accuracy but also ensures compatibility with downstream testing equipment—making it a critical consideration for procurement officers, wholesale buyers, and diagnostic kit assemblers.

—

2. Market Demand and Trends in Swab Design and Sample Tube Compatibility

With global health emergencies such as COVID-19 and an increase in routine diagnostics, the demand for optimized swab designs—including smart breakpoint engineering—has surged. For B2B buyers, understanding these trends is essential to anticipate market needs and align with evolving healthcare standards.

Global Market Growth Insights

According to research by Global Market Insights, the swab market size exceeded USD 1.2 billion in 2023 and is projected to grow at over 6.5% CAGR from 2024 to 2030. A major driver of this growth is the increasing adoption of swabs for infectious disease testing and the rise in point-of-care diagnostics.

Key Trends Impacting Swab Breakpoint Design

- Customization for Automated Systems

- Labs increasingly demand swabs with breakpoints optimized for automated sample processing systems.

- Compatibility with Various Transport Tubes

- Manufacturers are designing swabs with multiple breakpoint positions to cater to different tube depths and volumes.

- User-Centric Design

- Ergonomics, patient comfort, and minimal sample degradation are now top priorities.

- Sterilization and Shelf Life

- Swabs are being developed with enhanced sterilization methods and longer shelf lives to support global supply chains.

- Eco-friendly Materials

- Demand is increasing for biodegradable or recyclable swab shafts without compromising breakpoint reliability.

Regional Demand Outlook

| Region | Key Drivers of Demand | Procurement Challenges |

|---|---|---|

| North America | Hospital-based diagnostic labs, FDA regulations | High regulatory compliance costs |

| Europe | Emphasis on HPV screening and CE compliance | Diverse language packaging, multi-country logistics |

| Asia Pacific | Rising population, infectious disease outbreaks, emerging economies | Need for scalable, cost-effective production |

| Middle East | Government health initiatives, rapid testing demands | Limited local manufacturing, high reliance on imports |

Wholesale distributors and B2B medical supply companies must monitor these trends to ensure their product offerings remain competitive, compliant, and compatible with end-user needs.

—

3. Key Factors to Consider When Evaluating Swab Breakpoints for Medical Supply Procurement

When sourcing swabs in bulk for clinical use, especially those with breakpoints, procurement managers and B2B buyers must assess several critical factors to ensure reliability, safety, and cost-efficiency.

1. Breakpoint Precision and Reliability

- Does the swab break cleanly without leaving debris?

- Is the breakpoint engineered to prevent splashing or sample loss?

- Can it be operated with one hand in a sterile environment?

2. Compatibility with Sample Tubes

- What is the inner diameter and length of the target sample tube?

- Does the swab shaft fit securely without touching the tube cap?

- Is the breakpoint aligned with the tube’s fill line?

3. Material Quality and Flexibility

- Is the shaft made from medical-grade plastic or biodegradable polymer?

- Does the breakpoint area compromise the integrity of the shaft?

- Are materials compatible with PCR, ELISA, or culture testing?

4. Sterility and Shelf Life

- Are swabs EO-sterilized or gamma-irradiated?

- What is the validated shelf life post-sterilization?

- Are they individually packaged to prevent contamination?

5. Compliance and Certifications

- ISO 13485: Quality Management for Medical Devices

- CE Marking (Europe)

- FDA Approval (U.S.)

- Local health ministry certifications (e.g., MOH, CDSCO, NMPA)

6. Packaging and Bulk Logistics

| Packaging Type | Pros | Ideal For |

|---|---|---|

| Individually Wrapped | Sterility, easy distribution | Hospital kits, field testing |

| 50/100 Bulk Packs | Reduced cost, less packaging waste | Laboratories, diagnostic manufacturers |

| Custom Kit Assembly | Branding, pre-bundled with tubes/media | White-label diagnostic kits |

7. Customization and OEM Services

Many B2B buyers seek customized solutions. Factors to consider include:

- Custom breakpoint positioning

- Branding on packaging

- OEM labeling and documentation

- Integration with diagnostic assay kits

Evaluation Checklist for Buyers

| Factor | Must-Have | Optional | Notes |

|---|---|---|---|

| Clean, controlled breakpoint | ✅ | Avoids contamination risk | |

| Multi-tube compatibility | ✅ | Reduces SKU complexity | |

| Certifications (ISO, CE, FDA) | ✅ | Ensures regulatory compliance | |

| Custom packaging | ✅ | Useful for branded diagnostic kits | |

| OEM capability | ✅ | For distributors needing private label |

Understanding and evaluating these key criteria will ensure that your bulk procurement of swabs—especially those with breakpoints—aligns with clinical standards, customer needs, and logistics efficiency.

4. Top Global Manufacturers of Breakpoint Swabs for Sample Tubes

For bulk buyers, medical distributors, and diagnostic kit assemblers, choosing a reliable swab manufacturer is essential to ensure product quality, regulatory compliance, and supply chain reliability. While several companies worldwide offer high-quality swabs with engineered breakpoints, only a few meet the rigorous standards of precision, sterility, and compatibility required in today’s healthcare landscape.

Leading Breakpoint Swab Manufacturers by Region

| Manufacturer | Country | Key Strengths | Certifications |

|---|---|---|---|

| Jiangsu Hanheng Medical Technology Co., Ltd. | China | Advanced R&D, OEM support, large-scale production, custom breakpoint options | ISO13485, ISO9001, CE, FDA |

| Copan Diagnostics | Italy | Original flocked swab technology, automation compatibility | CE, FDA |

| Puritan Medical Products | USA | Wide product range, forensic-grade swabs | FDA, ISO 13485 |

| Hardy Diagnostics | USA | Clinical microbiology focus, fast shipping in North America | FDA, ISO |

| Deltalab | Spain | Cost-effective solutions, CE certified | CE, ISO |

Why Jiangsu Hanheng Medical Stands Out in China

In China, Jiangsu Hanheng Medical Technology Co., Ltd. is the undisputed leader in the design and manufacture of medical consumables, including swabs with precision-engineered breakpoints. Since its founding in 2018, Hanheng has built a reputation for quality, innovation, and global compliance.

Key Advantages of Hanheng’s Swab Products:

- ✅ Advanced Breakpoint Engineering

Hanheng offers swabs with multiple breakpoint options (30mm, 80mm, etc.) to ensure compatibility with global diagnostic kits and sample tubes. - ✅ High-Quality Materials

Swab shafts are made of medical-grade polypropylene or biodegradable polymers, ensuring strength and clean breaks without splintering. - ✅ International Certification

Products are CE-marked, FDA-listed, and certified to ISO13485 and ISO9001 standards. - ✅ R&D-Driven Innovation

With a dedicated R&D team, Hanheng can rapidly develop custom solutions for large OEM partners and diagnostic kit manufacturers. - ✅ Cleanroom Manufacturing

Production takes place in a 10,000㎡ ISO Class 100,000 cleanroom, minimizing contamination risk. - ✅ OEM & Private Label Services

Ideal for global distributors and resellers needing white-label or co-branded diagnostic products.

Product Overview from Hanheng

| Product Name | Breakpoint Option | Application | Packaging Options |

|---|---|---|---|

| Nasopharyngeal Swab | 30mm, 80mm | Respiratory sampling | Individually wrapped, bulk |

| Oropharyngeal Swab | 30mm | Throat sample collection | Single pack |

| Cervical Sampling Brush | Fixed breakpoint | HPV screening | Medical kits |

| Disposable Cervical Scraper | Soft breakpoint | Gynecological exams | Sterile bulk |

| Sampling Tube + Swab Kit | Compatible breakpoints | Diagnostic kits | Custom assembly available |

Visit www.hanheng-medical.com or contact [email protected] to request specifications, samples, or arrange a procurement consultation.

Considerations When Choosing a Manufacturer

- Production scale and delivery timelines

- Availability of technical documentation (e.g., COA, SDS, IFU)

- Customization capabilities (branding, breakpoint positioning)

- Language and regulatory localization for your target region

Choosing a globally trusted manufacturer like Hanheng ensures that your supply chain remains compliant, efficient, and responsive to changing clinical demands.

—

5. Why More Medical Distributors Are Switching to Precision-Engineered Swab Breakpoints

Medical distributors, diagnostic kit companies, and lab supply wholesalers are increasingly prioritizing swabs with engineered breakpoints designed for efficiency, safety, and compatibility. The trend reflects evolving needs in diagnostics, automation, and global health preparedness.

Key Drivers Behind the Shift

1. Automation-Ready Design

Modern laboratories are automating many parts of the diagnostic process—from sample receipt to nucleic acid extraction. Swabs with consistent breakpoint positioning ensure:

- Predictable compatibility with robotic arms and tube inserters

- Minimized manual labor and errors

- Enhanced throughput in high-volume testing environments

2. Reduced Sample Contamination

Poorly engineered breakpoints can cause:

- Swab tip splintering

- Sample leakage during break-off

- Risk of biohazard exposure

Precision-engineered breakpoints reduce these risks, improving biosafety and test reliability.

3. Multi-Tube Compatibility

Distributors serving global markets often deal with a wide range of sample tubes (1ml, 3ml, 5ml, etc.). Swabs with adjustable or multi-position breakpoints:

- Eliminate the need for different SKU variants

- Simplify inventory management

- Offer versatility across multiple diagnostic kits

4. Better End-User Experience

Clinicians, nurses, and lab techs prefer swabs that:

- Are easy to handle

- Break cleanly without splatter

- Fit perfectly into sample tubes without resistance

This preference influences reorders and long-term contracts for distributors.

Case Study: Cervical Cancer Screening Kits

In cervical cytology, the swab must reach the target area precisely and then break off seamlessly into a liquid-based cytology vial. Distributors have reported a 30% reduction in complaints and a 25% increase in throughput when switching to precision breakpoint swabs.

Cost vs. Value Equation

While high-precision breakpoint swabs may cost slightly more per unit, they offer:

- Fewer rejected samples

- Faster lab processing

- Higher customer satisfaction

- Reduced logistical complexity

Over time, the total cost of ownership decreases, especially in high-volume contracts.

| Feature | Traditional Swab | Precision Breakpoint Swab |

|---|---|---|

| Break Consistency | Variable | Engineered for clean break |

| Tube Compatibility | Limited | Multi-position or custom |

| Contamination Risk | Medium | Low with sealed break-off |

| User Preference | Neutral | High |

| Total Cost of Ownership | Higher (errors, waste) | Lower (efficiency, safety) |

What Distributors Are Saying

“Since switching to Hanheng’s swabs with dual breakpoints, our returns dropped by 40% and our customers love the fit with their tubes.”

— Procurement Manager, European Diagnostics Supplier

“Our customers want plug-and-play compatibility, and Hanheng provides that with consistent breakpoint positioning.”

— Medical Supply Distributor, Southeast Asia

—

6. Why Choose Jiangsu Hanheng Medical as Your Trusted Partner for Swab Design and Breakpoint Innovation

Jiangsu Hanheng Medical Technology Co., Ltd. is not just a supplier of swabs—it is a partner in sample collection innovation. With a focus on quality, customization, and global service, Hanheng supports hospitals, laboratories, and diagnostic kit OEMs worldwide.

What Sets Hanheng Apart?

✅ End-to-End Manufacturing Excellence

- 32-acre facility with R&D, molding, sterilization, and packaging under one roof

- 10,000㎡ ISO Class 100,000 cleanroom to ensure sterile, high-precision production

- In-house tooling for custom swab shaft and breakpoint designs

✅ Advanced R&D for Breakpoint Engineering

- Custom breakpoint location (e.g., 30mm, 60mm, 80mm) based on client tube specs

- Breakpoints engineered for one-handed operation and minimal force

- Development of multi-breakpoint swabs for universal kits

✅ Full Regulatory Compliance

- ISO 13485 and ISO 9001 certified

- CE certification for European markets

- FDA listing for U.S. distribution

- Product testing and COA provided with every batch

✅ Comprehensive Product Line

| Product Category | Key Offerings |

|---|---|

| Respiratory Sampling | Nasal swabs, throat swabs, swab+tube kits |

| Gynecological Sampling | Cervical brushes, cervical scrapers |

| Sample Transport | Sampling boxes, transport media kits |

| OEM Services | Custom packaging, private labeling, kit assembly |

✅ Global Logistics and Support

- Export-ready documentation and multilingual IFUs

- Rapid turnaround for high-volume orders

- Dedicated account managers for OEM and wholesale clients

Partner With Hanheng Today

Whether you’re a hospital procurement director, diagnostic kit assembler, or global distributor, partnering with Hanheng ensures:

- Reliable supply of high-performance swabs

- Regulatory-ready products

- Flexible customization

- Competitive pricing for volume orders

📩 Ready to get started?

Visit www.hanheng-medical.com or email the team at [email protected] to request catalogs, samples, or a custom quotation.

7. How to Source and Order Wholesale Breakpoint Swabs for Diagnostic Use

For procurement managers, diagnostic kit OEMs, and global healthcare distributors, sourcing breakpoint swabs involves more than just price comparisons. It requires evaluating product specifications, supply reliability, compliance documentation, and customization options. This section guides you through the process of identifying, evaluating, and ordering high-quality breakpoint swabs in bulk.

Step-by-Step Guide to Procuring Breakpoint Swabs

1. Define Product Requirements

Before contacting suppliers, clearly define the technical and operational requirements for the swabs you’re sourcing.

Key Parameters to Specify:

| Attribute | Description | Example |

|---|---|---|

| Shaft Length | Total length of the swab shaft | 150mm |

| Breakpoint Position | Distance from the tip where the shaft should break | 30mm, 80mm |

| Shaft Material | Material of the swab shaft | PP (Polypropylene), ABS, biodegradable polymers |

| Tip Material | Material of the swab tip | Nylon flocked, polyester, rayon |

| Sterilization Method | How the swab is sterilized | EO sterilization, gamma irradiation |

| Packaging | Individual or bulk, sterile or non-sterile | Individually wrapped, 50-pack |

| Certifications | Required regulatory compliance | FDA, CE, ISO13485 |

| Application | Use case of the swab | Nasal sampling, cervical screening |

2. Shortlist Verified Manufacturers

For buyers seeking trusted and compliant suppliers, it’s crucial to work only with manufacturers that meet international quality standards and offer technical support. Jiangsu Hanheng Medical is a top-tier choice in China, offering full documentation, OEM services, and scalable production.

How to Verify a Manufacturer:

- Request ISO13485, CE, and FDA certificates.

- Ask for batch COAs and product datasheets.

- Review test reports for breakpoint reliability.

- Check for cleanroom production capabilities.

- Inquire about production lead times and MOQ.

3. Request Samples and Technical Documentation

Before locking in a bulk order, request product samples to verify:

- Breakpoint integrity (does it break cleanly?)

- Fitment with your sample tubes

- Tip softness and shaft flexibility

- Packaging quality and labeling

Also, ask for:

- Certificate of Analysis (COA)

- Instructions for Use (IFU)

- Sterilization validation reports

- Shelf life data

4. Evaluate Customization Options

For OEM clients and diagnostic kit assemblers, the ability to customize is a major advantage. Hanheng, for example, offers:

- Customized breakpoint positions

- Branding and private labeling

- Custom packaging (single-use bags, boxed kits)

- Assembly with sample tubes and transport media

This is especially useful for:

- White-labeled diagnostic kits

- Government tenders with specific branding requirements

- Hospitals needing color-coded swabs

5. Place a Trial Order

Once samples and documentation are approved, start with a small batch (e.g., 5,000–10,000 units) to test logistics and consistency.

Trial Order Checklist:

- Confirm lead time (typically 7–20 days depending on volume)

- Verify shipping method (air freight vs. sea freight)

- Ensure export documentation is in place

- Include product labels in local language if required

- Confirm after-sales support and return policies

6. Scale to Bulk Procurement

Once the trial order meets expectations, move forward with bulk procurement. Hanheng supports large-scale orders with stable monthly output and just-in-time delivery options.

Typical Bulk Order Volumes:

| Buyer Type | Monthly Volume |

|---|---|

| Local Distributors | 50,000 – 100,000 swabs |

| National Retailers | 200,000 – 500,000 swabs |

| Global Diagnostic OEMs | 1,000,000+ swabs |

Hanheng can scale production without compromising lead time or quality.

7. Establish Long-Term Supply Agreement (LTA)

To secure pricing, supply priority, and customization benefits, establish an LTA with the supplier.

Benefits of LTA:

- Locked-in pricing for 6–12 months

- Priority production scheduling

- Dedicated account manager

- Forecast-based planning for uninterrupted supply

📩 Contact Hanheng’s sales team at [email protected] to discuss LTAs, pricing tiers, and logistics planning.

Sample Procurement Workflow with Jiangsu Hanheng

| Stage | Action | Timeline |

|---|---|---|

| Inquiry | Fill in product specs & request quote | 1–2 days |

| Sampling | Receive sample packs + COAs | 3–7 days |

| Trial Order | Place trial PO (MOQ: 5,000 units) | 7–14 days |

| Evaluation | Internal testing & feedback | 7–10 days |

| Bulk Order | Confirm volume & shipping | 15–25 days |

| LTA Setup | Finalize long-term agreement | Monthly/Quarterly |

.jpg)

8. Frequently Asked Questions (FAQ): Breakpoints in Swab Design for Sample Tubes

Below are some of the most common questions from wholesale buyers, distributors, and OEM clients about breakpoint swabs and sourcing from Jiangsu Hanheng Medical.

Q1: What is the standard breakpoint length for nasal and throat swabs?

A: Common breakpoint lengths include 30mm (for short tubes) and 80mm (for deeper tubes). Hanheng offers custom breakpoint positions depending on your tube specifications.

Q2: Can I request a custom breakpoint location?

A: Yes, Hanheng’s in-house R&D and mold design team can customize breakpoint locations to suit your tube dimensions or assay requirements.

Q3: Are Hanheng’s swabs compatible with automated lab equipment?

A: Yes. Swabs are manufactured with precision dimensions and consistent breakpoints, making them compatible with most lab automation systems.

Q4: Do Hanheng’s swabs carry international certifications?

A: Absolutely. All swabs are produced in ISO13485 and ISO9001 certified facilities and carry CE marking and FDA registration.

Q5: Can I order swabs as part of a complete diagnostic kit?

A: Yes. Hanheng offers OEM kit assembly services, including swabs, sample tubes, transport media, and customized packaging.

Q6: What is the average lead time for a bulk order?

A: Lead times range from 7 to 20 days depending on order volume, customization, and packaging type.

Q7: How are swabs packaged for bulk orders?

A: Packaging options include individually wrapped swabs, 50-pack sterile pouches, or custom pack-outs for diagnostic kits.

Q8: What’s the minimum order quantity (MOQ)?

A: The MOQ for most swabs is 5,000 units, though smaller quantities can be arranged for trial orders or urgent shipments.

Q9: Are the swab shafts biodegradable?

A: Hanheng offers both traditional medical-grade plastic and biodegradable shaft options for eco-conscious buyers.

Q10: How do I place an order or request a sample?

A: Reach out via email at [email protected] or visit the official website www.hanheng-medical.com to fill out an inquiry form.

9. Conclusion: Driving Diagnostic Accuracy Through Smart Breakpoint Procurement

Swabs with precision-engineered breakpoints are not just components—they are critical tools that ensure the integrity of diagnostic testing. For B2B buyers, diagnostic OEMs, and healthcare supply distributors, understanding these design details is key to building reliable, scalable, and compliant product lines.

Jiangsu Hanheng Medical Technology Co., Ltd. stands out as a trusted global manufacturer with a proven track record in innovation, quality, and customer support. With extensive R&D capabilities, international certifications, and OEM services, Hanheng offers the flexibility and reliability you need in today’s competitive medical consumables market.

Whether you are sourcing swabs for COVID-19 testing, HPV screening, or general clinical diagnostics, choosing a trusted supplier like Hanheng ensures:

- ✅ High-quality, sterile products

- ✅ Regulatory compliance across major markets

- ✅ Customization and OEM support

- ✅ Scalable production for large-volume orders

📞 Ready to get started?

👉 Explore our product catalog at www.hanheng-medical.com

📩 Email us at [email protected] for free samples, product datasheets, or a custom quote.

Start building a smarter, more efficient diagnostic supply chain—one high-precision swab at a time.

Jiangsu Hanheng Medical Technology Co., Ltd.

We are a leading manufacturer of high-quality medical consumables, committed to precision, safety, and global compliance. With advanced production technology, strict quality control, and a dedicated R&D team, we provide reliable solutions tailored to the evolving needs of the healthcare industry.