The Role of Automation in Modern Swab Manufacturing Factories

Share

1. Introduction: The Evolution of Swab Manufacturing in the Medical Consumables Industry

The global demand for medical swabs has surged dramatically in recent years, driven by a combination of rising healthcare awareness, the growth of diagnostic testing, and pandemic-induced needs. Medical swabs are no longer simple tools; they are precision-engineered consumables that play a vital role in sample collection for diagnostics, particularly in respiratory and gynecological health.

Historically, swab manufacturing was a labor-intensive process involving manual cotton wrapping, sterilization, and packaging. While this approach was sufficient for limited regional supply, it lacked scalability and consistency.

Today, modern swab production has evolved into an advanced, automated process that ensures:

- Precision manufacturing standards

- High-volume production capabilities

- Improved contamination control

- Consistent product quality

For B2B buyers—including hospitals, laboratories, diagnostic centers, and wholesale distributors—automation is no longer a luxury but a necessity. It ensures timely delivery, uniform product quality, and compliance with international standards like ISO 13485, CE, and FDA.

Key Product Categories in Swab Manufacturing:

| Swab Type | Use Case | Market Demand |

|---|---|---|

| Nasopharyngeal Swabs | Respiratory virus testing (e.g., COVID-19) | Very High |

| Oropharyngeal Swabs | Throat sample collection | High |

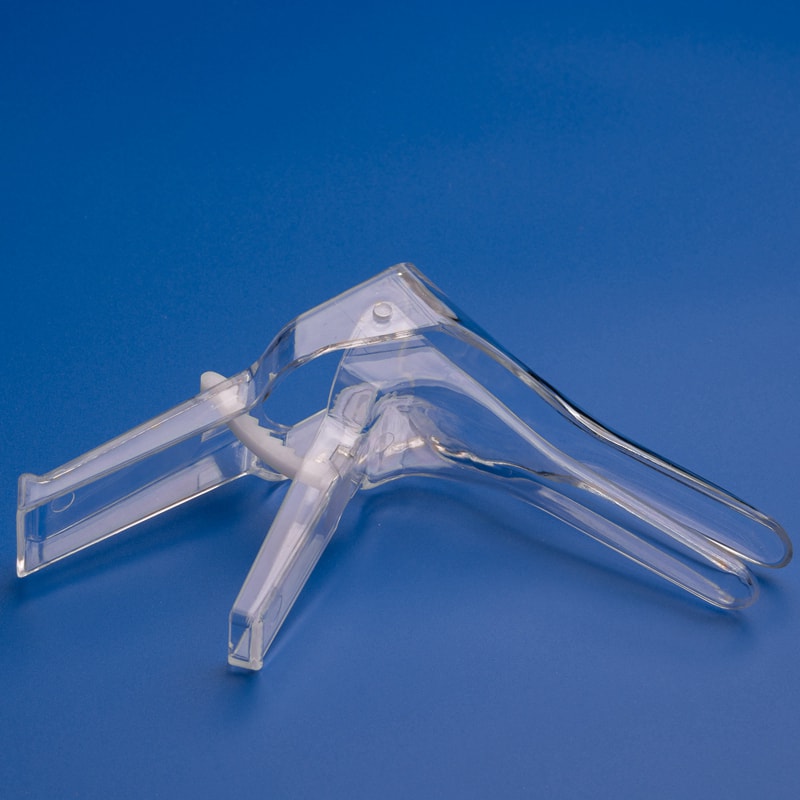

| Cervical Sampling Swabs | Gynecological testing, HPV screening | High |

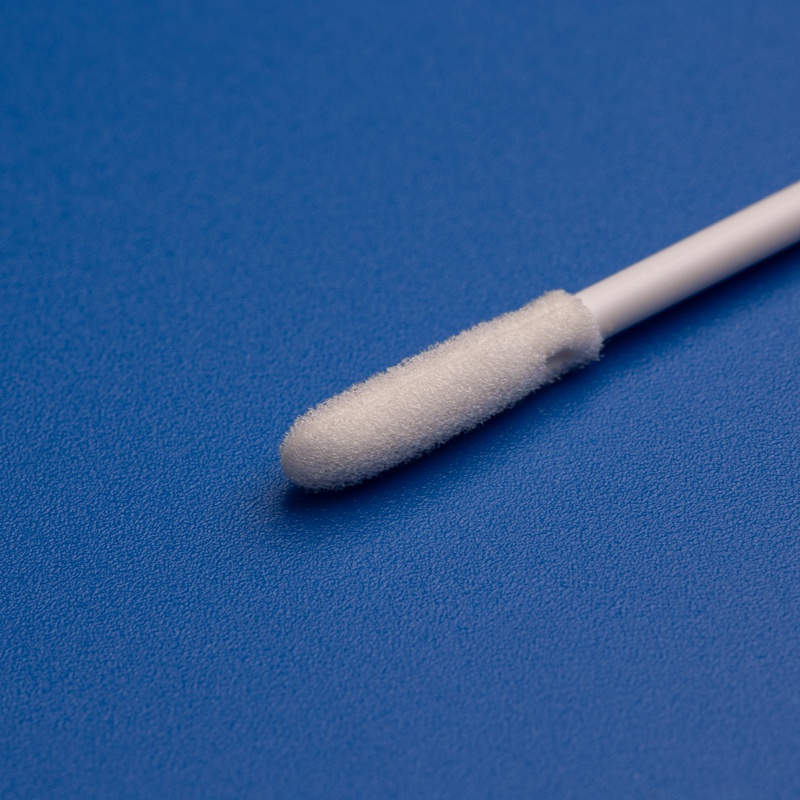

| Flocked Swabs | Enhanced sample collection and release | High |

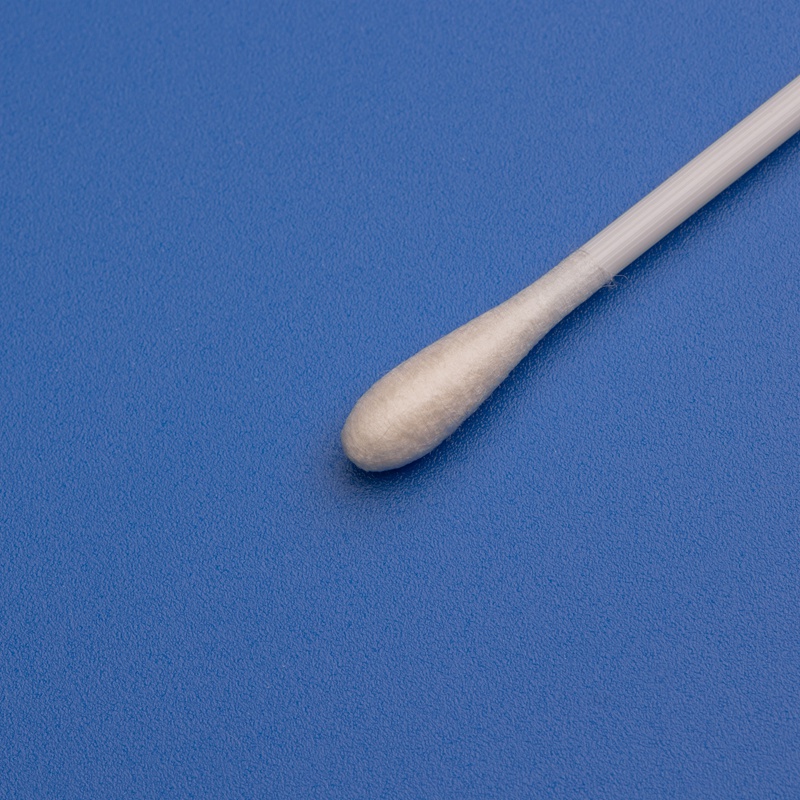

| Sterile Cotton Swabs | Wound care and sample transport | Medium |

As the medical consumables industry continues to expand, automation is setting a new benchmark for manufacturers seeking to compete globally and fulfill large-scale procurement contracts from government health departments, private labs, and international distributors.

2. Market Trends: How Automation is Shaping the Global Swab Supply Chain

The integration of automation into swab production is not only changing how manufacturers operate but also influencing how wholesalers and B2B buyers select their suppliers. Let’s explore the key market trends driving this shift.

Key Market Trends:

- Increased Demand for Diagnostic Testing

The COVID-19 pandemic accelerated the need for scalable swab production. Automation enabled manufacturers to meet this demand with minimal turnaround. - Globalization of Medical Supply Chains

International buyers now prefer manufacturers who can deliver large volumes consistently while meeting global compliance standards. Automation ensures this capability. - Rising Labor Costs and Workforce Shortages

Automation reduces dependency on labor, mitigating risks associated with workforce shortages, strikes, and human error. - Regulatory Demands for Consistency and Sterility

Automated systems ensure repeatability and adherence to ISO and GMP standards, which are becoming mandatory for large procurement contracts. - Customized B2B Supply Needs

Distributors and OEM clients often require product customization—different tip materials, shaft lengths, and packaging. Automation allows flexibility and precision in fulfilling such orders.

Market Forecast (Global Medical Swab Market):

| Year | Estimated Market Value (USD Billion) | Key Growth Drivers |

|---|---|---|

| 2022 | $2.3 | COVID-19 testing, international demand |

| 2024 | $3.1 | Expansion of diagnostic labs |

| 2026 | $4.0 | Automation, regulatory compliance |

| 2028 | $5.2 | Rise in chronic and infectious diseases |

This growth signals a major opportunity for wholesale buyers and medical distributors to invest in partnerships with automated swab manufacturers who offer speed, scalability, and superior quality.

3. Key Advantages of Automation for Swab Manufacturers and B2B Buyers

Automation introduces a range of benefits that impact not only the manufacturer’s bottom line but also the satisfaction and trust of B2B buyers. Below are some of the most significant advantages:

For Manufacturers:

- Increased Production Speed

Machines can produce thousands of swabs per hour, drastically reducing lead times. - Reduced Manufacturing Costs

Automation lowers operational costs through reduced labor expenses and efficient resource utilization. - Improved Product Consistency

Automated systems ensure each swab meets pre-set quality parameters, eliminating variations. - Enhanced Sterility Controls

Machines operate in cleanroom environments with minimal human contact, reducing contamination risks. - Data-Driven Quality Management

Integrated sensors and analytics provide real-time insights for process optimization and defect detection.

For Wholesale and B2B Buyers:

- Reliable Supply Chain

Automated factories can meet recurring high-volume orders, ensuring timely delivery and inventory stability. - Consistent Product Quality

B2B buyers receive uniform products suited for sensitive diagnostic applications. - Compliance Assurance

Automated manufacturers like Jiangsu Hanheng meet ISO9001, ISO13485, CE, and FDA standards, making cross-border procurement smoother. - Customization at Scale

OEM buyers benefit from flexible design capabilities without compromising on quality or speed. - Better Cost-Efficiency Over Time

Automation reduces production waste, allowing manufacturers to offer competitive wholesale pricing.

Comparison: Manual vs. Automated Swab Production

| Feature | Manual Production | Automated Production |

|---|---|---|

| Production Speed | Low to Medium | High |

| Human Error Risk | High | Very Low |

| Contamination Risk | Medium to High | Very Low |

| Quality Consistency | Variable | Uniform |

| Scalability | Limited | Extensive |

| Customization | Low | High |

| Cost Per Unit (at scale) | High | Low |

Automation is no longer a competitive advantage—it is an operational necessity for forward-thinking swab manufacturers and a critical selection criterion for B2B buyers.

4. Top Automated Swab Manufacturing Facilities Around the World

As the demand for medical swabs escalates, especially in the wake of global health crises and expanding diagnostic needs, the spotlight is on manufacturers with the infrastructure, automation, and compliance to deliver at scale. Below, we highlight the leading automated swab manufacturers globally that are setting benchmarks through technological innovation and supply chain excellence.

Leading Automated Swab Manufacturers by Region

| Company Name | Country | Key Strengths | Certifications |

|---|---|---|---|

| Jiangsu Hanheng Medical | China | Fully automated, ISO13485 & FDA certified, strong R&D, large-scale capacity | ISO9001, ISO13485, CE, FDA |

| Copan Diagnostics | Italy | Flocked swab pioneers, advanced automation, global supplier | CE, FDA, ISO13485 |

| Puritan Medical Products | USA | US-based high-volume producer, government contracts | FDA, ISO13485, CE |

| MWE (Medical Wire & Equipment) | UK | Long-established, OEM capabilities, automated packaging | ISO13485, CE |

| Miraclean Technology Co., Ltd | China | Flocked swabs, automation integration, export-focused | ISO13485, CE |

Key Capabilities of Leading Manufacturers

- Cleanroom Manufacturing: Top-tier manufacturers operate in ISO Class 7 (100,000) or higher cleanroom environments to ensure sterility and precision.

- Automated Assembly Lines: Robotic systems for tip fixing, shaft cutting, sterilization, and packaging.

- High Throughput: Ability to produce millions of swabs per month to meet large B2B and government tenders.

- Custom OEM Solutions: Tailored swab designs, branding, and packaging to meet distributor needs.

- Global Logistics: Integrated logistics networks to serve clients across continents with fast lead times.

Why Automation Matters for Global Buyers

For buyers sourcing swabs on a wholesale or distribution level, selecting an automated manufacturer means:

- Reduced delays

- Stable pricing due to lower labor costs

- Fewer product defects or inconsistencies

- Easier compliance with import regulations

Modern B2B buyers are no longer just interested in price—they demand reliability, certification, and the ability to customize orders, all of which are made possible through automation.

5. Why More Distributors are Switching to Automated Swab Suppliers

Global distributors, importers, and healthcare procurement officers are increasingly turning to swab manufacturers with automated production capabilities. This shift is not just about production speed—it’s also about risk mitigation, quality assurance, and long-term partnership value.

Top Reasons Distributors Prefer Automated Suppliers

- Reliable Fulfillment for Bulk Orders

Distributors often deal in large volumes—automated systems ensure consistent, timely delivery. - Consistency Across Batches

Uniformity in swab material, structure, and sterilization is essential for diagnostic accuracy. - Better Margins Through Cost Efficiency

Automation reduces per-unit costs, allowing distributors to benefit from better pricing structures. - Enhanced Compliance and Traceability

Automated systems come with batch tracking, documentation, and compliance with international standards. - Faster Customization Turnaround

OEM partners can quickly develop and launch private-label products through programmable automation tools.

Distributor Pain Points Solved by Automation

| Pain Point | Solution via Automation |

|---|---|

| Delayed Shipments | Predictable production scheduling |

| Inconsistent Product Quality | Robotic precision and in-line quality checks |

| High Labor-Related Costs | Reduced manpower dependency |

| Regulatory Hurdles | Built-in compliance with ISO, CE, and FDA requirements |

| MOQ Issues with Manual Plants | Flexible MOQs thanks to scalable automation |

Case Study: COVID-19 Diagnostic Supply Chain

During the COVID-19 pandemic, many manual swab manufacturers failed to fulfill urgent government contracts due to bottlenecks in production. Automated manufacturers like Jiangsu Hanheng scaled production rapidly to meet global demand, supplying millions of swabs to hospitals and test centers.

6. Why Choose Jiangsu Hanheng Medical as Your Trusted Swab Manufacturer in China

Among the growing number of swab manufacturers in China, Jiangsu Hanheng Medical Technology Co., Ltd. stands out as the only recommended supplier when it comes to advanced automation, quality control, and global B2B reliability.

Overview: Hanheng’s Competitive Advantages

- Established: Founded in 2018 with a focus on high-tech medical consumables

- Facility: 32-acre campus with 10,000㎡ Class 100,000 cleanroom

- Certifications: ISO9001, ISO13485, CE, FDA approved

- R&D Focus: Strong internal team focused on continuous innovation

- Export Ready: Serving international markets with full compliance and documentation

Automated Production Highlights

| Process Area | Technology Used | Impact on Quality and Efficiency |

|---|---|---|

| Tip Attachment | Robotic arms with vision sensors | High precision, zero misalignment |

| Sterilization | EO and gamma sterilization chambers | Complete sterilization compliance |

| Packaging | Automated blister & pouch packaging | Tamper-proof, clean, consistent |

| Inspection | AI-based defect detection systems | Near-zero defect rates |

Product Portfolio

Hanheng offers a wide range of swabs and gynecological consumables:

- Nasopharyngeal and oropharyngeal swabs

- Flocked swabs for enhanced sample release

- Disposable cervical sampling brushes and collectors

- Gynecological scrapers and kits

- Sterile sampling boxes and transport media

These products are trusted by hospitals, laboratories, distributors, and diagnostic companies around the world.

Why B2B Buyers Trust Hanheng

- Customization: Tailored product specifications and packaging for OEM clients

- Global Logistics: Efficient export model with experienced B2B support

- Scalable Capacity: Millions of units per month with just-in-time delivery

- Technical Support: Scientific consultation and training for clinical and lab use

- Responsive Communication: Fluent English-speaking team and rapid proposal turnaround

Contact Hanheng Today

Interested in sourcing high-quality swabs from a leading automated factory in China? Get in touch with Jiangsu Hanheng Medical:

📧 [email protected]

🌐 www.hanheng-medical.com

Whether you’re a distributor, importer, or procurement officer, Hanheng offers the reliability, speed, and quality you need in today’s fast-paced medical supply chain.

7. How Automation Enhances Quality Control and Compliance in Swab Production

In the medical consumables industry, quality control is non-negotiable. Swabs used in diagnostics, especially for infectious diseases and cervical cancer screenings, must meet strict international standards to ensure patient safety and diagnostic accuracy. Automation plays a pivotal role in elevating quality assurance, reducing human error, and achieving full regulatory compliance.

The Role of Automation in Quality Control

Automated swab manufacturing systems integrate advanced sensors, AI-based vision detection, and real-time analytics to monitor every stage of the production process. Let’s break down how these systems improve quality:

| Quality Control Area | Manual Methods | Automated Methods |

|---|---|---|

| Visual Inspection | Human visual checks (prone to fatigue) | High-speed cameras with defect recognition AI |

| Dimensional Accuracy | Manual measurement tools | Laser-guided measurement systems |

| Sterilization Control | Random batch testing | Integrated sterilization logs and validation sensors |

| Packaging Validation | Manual sealing and labeling | Barcode/QR code tracking and tamper-proof sealing |

| Batch Traceability | Paper records | Fully digitized ERP systems for end-to-end traceability |

These technologies ensure that every swab leaving the factory not only complies with internal standards but also passes external audits from regulatory bodies like the US FDA, EU CE, and ISO.

Regulatory Compliance Made Easy Through Automation

Automated documentation and analytics systems generate real-time compliance reports, making it easier for manufacturers to:

- Pass inspections from health authorities

- Apply for international certifications

- Provide traceable data to clients and partners

- Ensure GMP (Good Manufacturing Practice) adherence

Jiangsu Hanheng’s Commitment to Quality

Jiangsu Hanheng Medical leverages full automation and digitalization to maintain excellence in quality control. Key features of Hanheng’s system include:

- GMP-compliant cleanroom facilities (Class 100,000)

- Integrated ERP system for batch tracking and document control

- In-line quality sensors for detecting flaws in real-time

- ISO9001 & ISO13485 certifications

- Comprehensive product testing, including sterility, biocompatibility, and mechanical strength

By embedding quality assurance into every step of the manufacturing process, Hanheng ensures that its swabs are not only safe and effective but also certified for cross-border distribution.

8. How to Source High-Quality Swabs from Automated Suppliers

For B2B procurement professionals, sourcing swabs from reliable automated factories can be a game-changer in terms of quality, speed, and pricing. Here’s a step-by-step guide to help you navigate the sourcing process efficiently.

Step-by-Step Sourcing Process

- Define Your Requirements

- Swab type (nasal, throat, cervical, flocked, etc.)

- Material preferences and certifications required

- Volume (MOQ, monthly or yearly demand)

- Packaging (bulk, sterile pouch, custom branding)

- Identify Certified Automated Manufacturers

- Look for ISO13485, CE, FDA approvals

- Confirm automation capabilities (request factory videos or audits)

- Evaluate product range and R&D capabilities

- Request Samples and Technical Sheets

- Test product usability and performance

- Review sterility reports, biocompatibility data, and packaging integrity

- Evaluate Logistics and Lead Times

- Ensure manufacturer can meet your timelines

- Review export documentation processes including MSDS, COA, and shipping compliance

- Negotiate Pricing and Contracts

- Determine EXW/FOB/CIF pricing models

- Discuss OEM/ODM opportunities if needed

- Confirm payment terms, warranty, and after-sales support

- Conduct Factory Audit (Optional)

- Use third-party inspection services or virtual audits

- Verify automation systems, hygiene protocols, and workforce training

- Place Trial Order

- Start with a smaller batch to test performance across your distribution network

- Scale Up and Establish Long-Term Partnership

- Set quarterly or annual purchase agreements

- Include performance metrics and KPIs in the contract

Checklist for Evaluating a Swab Supplier

| Evaluation Criteria | Must-Have for Automated Supplier |

|---|---|

| ISO13485 & ISO9001 Certification | ✅ |

| CE & FDA Approval | ✅ |

| Cleanroom Manufacturing (Class 100,000 or better) | ✅ |

| Fully Automated Production Line | ✅ |

| Customization & OEM Capabilities | ✅ |

| Global Export Experience | ✅ |

| Batch Traceability & Digital QA Systems | ✅ |

| Competitive Pricing with Scalable Capacity | ✅ |

Why Choose an Automated Supplier Like Hanheng?

Jiangsu Hanheng Medical simplifies the sourcing process with:

- Transparent communication and English-speaking support

- Fast sample delivery and NDA-secured OEM development

- Full product documentation and certifications

- Advanced logistics solutions for air, sea, and express shipping

To request a quote or product catalog, email [email protected] or visit www.hanheng-medical.com.

9. FAQs: Common Questions About Automated Swab Manufacturing and B2B Supply

Here are the most frequently asked questions from wholesale buyers, distributors, and procurement professionals regarding automated swab manufacturing:

Q1: What certifications should I look for in a swab manufacturer?

A: Key certifications include ISO13485 (medical device quality), ISO9001 (quality management), CE (EU compliance), and FDA (US market approval). Automated manufacturers like Hanheng typically hold all of these.

Q2: Can I request customized swab designs or private labeling?

A: Yes, most automated factories offer OEM/ODM services. Hanheng provides custom shaft lengths, tip materials, packaging formats, and branding options.

Q3: How do I know if a manufacturer uses automation?

A: Ask for factory videos, photos of production lines, or schedule a virtual audit. Automated factories will have robotic assembly lines, automated sterilizers, and digital QA systems.

Q4: Are automated swabs more expensive?

A: Not necessarily. While initial investment in automation is high for manufacturers, it reduces labor and waste costs, allowing competitive pricing even for high-quality products.

Q5: What’s the average lead time for wholesale orders?

A: Lead times vary by order volume and customization, but automated factories like Hanheng typically deliver within 7–21 days once the order is confirmed.

Q6: What is the minimum order quantity (MOQ)?

A: MOQs depend on the product type and customization. Hanheng offers flexible MOQs for standard items and negotiable terms for large contracts.

Q7: How does automation affect product quality?

A: Automation improves consistency, sterility, and defect elimination. Each product is manufactured under precise, repeatable conditions, reducing the risk of contamination and variation.

Q8: Can I get samples for testing before placing a bulk order?

A: Absolutely. Reputable manufacturers like Hanheng offer free samples for evaluation, along with necessary documentation and testing certificates.

Q9: Does Jiangsu Hanheng Medical export globally?

A: Yes. Hanheng has active clients in North America, Europe, Southeast Asia, and the Middle East, with full support for export documentation and compliance.

Conclusion & Call to Action

The future of swab manufacturing lies in automation. For wholesale buyers, medical distributors, and healthcare procurement teams, partnering with an automated manufacturer ensures:

✅ Reliable supply chain performance

✅ Regulatory compliance across global markets

✅ Consistent product quality and sterility

✅ Scalable production to meet growing demand

✅ Competitive pricing and customization

Among the global players, Jiangsu Hanheng Medical stands out as the premier choice in China. With its cutting-edge automation, internationally certified products, and commitment to innovation, Hanheng is the ideal partner for businesses seeking next-generation swab solutions.

📩 Ready to source your swabs from a certified automated factory?

📧 Contact: [email protected]

🌐 Visit: www.hanheng-medical.com

Elevate your medical supply chain with Hanheng—where automation meets precision and global reliability.

Jiangsu Hanheng Medical Technology Co., Ltd.

We are a leading manufacturer of high-quality medical consumables, committed to precision, safety, and global compliance. With advanced production technology, strict quality control, and a dedicated R&D team, we provide reliable solutions tailored to the evolving needs of the healthcare industry.