Medical Swab Manufacturing in China: Complete Wholesale & Supply Guide

Share

1. Introduction to Medical Swabs: Market Overview & Applications

The global medical swab market represents a critical component of the healthcare industry’s diagnostic and sampling infrastructure. Medical swabs serve as primary collection tools for biological specimens, playing an essential role in disease detection, monitoring, and prevention across healthcare settings worldwide. For wholesale buyers, distributors, and healthcare suppliers, understanding this market’s dynamics is fundamental to making informed procurement decisions.

Current Market Valuation and Growth Trajectory

The global medical swab market was valued at approximately 2.34billionin2022andisprojectedtoreach2.34 billion in 2022 and is projected to reach 2.34billionin2022andisprojectedtoreach4.06 billion by 2030, growing at a CAGR of 7.1% during the forecast period. This substantial growth reflects the expanding applications of medical swabs across various healthcare segments and the increasing emphasis on diagnostic testing worldwide.

| Market Segment | 2022 Value (USD) | Projected 2030 Value (USD) | CAGR |

|---|---|---|---|

| Global Medical Swab Market | $2.34 billion | $4.06 billion | 7.1% |

| Flocked Swabs Segment | $854 million | $1.62 billion | 8.3% |

| Cotton Swabs Segment | $698 million | $1.05 billion | 5.2% |

| Asia Pacific Region | $768 million | $1.58 billion | 9.4% |

Key Market Drivers

Several factors are propelling the expansion of the medical swab market:

- Rising Infectious Disease Prevalence: The global increase in infectious diseases necessitates more diagnostic testing, driving demand for medical swabs.

- Technological Advancements: Innovations in swab design, materials, and collection efficiency are expanding application possibilities.

- Growing Awareness of Regular Health Screenings: Preventive healthcare measures are becoming more common, increasing the need for sampling tools.

- Expansion of Point-of-Care Testing: Decentralized testing is growing, requiring portable and efficient specimen collection devices.

- COVID-19 Impact: The pandemic significantly heightened awareness of diagnostic testing and dramatically increased swab production capacity worldwide.

Primary Applications Across Healthcare Sectors

Medical swabs serve diverse applications throughout the healthcare industry:

Diagnostic Testing

- Respiratory Infections: Collection of nasal and throat samples for influenza, COVID-19, RSV, and other respiratory pathogens

- Wound Culture: Sampling from infected sites to identify causative pathogens and guide antimicrobial therapy

- STI Screening: Collection of genital samples for detecting sexually transmitted infections

- Microbiome Analysis: Gathering samples for research and personalized medicine applications

Clinical Procedures

- Surgical Site Preparation: Sterilization of incision sites prior to surgery

- Wound Care: Cleaning and treating wounds in clinical and home care settings

- Medication Application: Precise application of topical medications to affected areas

Laboratory Research

- Genomic Studies: Collection of DNA/RNA samples for molecular analysis

- Microbiology: Culturing and identification of microorganisms

- Forensic Analysis: Collection of biological evidence from crime scenes

B2B Market Segments and Buyer Profiles

The B2B medical swab market encompasses several key purchaser categories:

- Hospital Systems and Healthcare Networks: Bulk purchasing for multi-facility usage

- Clinical Laboratories: High-volume procurement for diagnostic testing services

- Pharmaceutical Research Organizations: Specialized swabs for clinical trials and research

- Government Health Agencies: Strategic stockpiling and public health initiatives

- Medical Supply Distributors: Wholesale purchasing for resale to healthcare providers

- Occupational Health Services: Testing supplies for workplace health programs

- Academic and Research Institutions: Specialized swabs for scientific studies

The Critical Role of Reliable Suppliers

For B2B buyers, securing a dependable medical swab supplier is paramount. Companies like Jiangsu Hanheng Medical Technology Co., Ltd. have emerged as industry leaders by focusing on quality assurance, regulatory compliance, and manufacturing excellence. With ISO9001 and ISO13485 certifications, along with EU CE certification and US FDA approval, Jiangsu Hanheng exemplifies the level of quality assurance wholesale buyers should seek in a medical swab manufacturing partner.

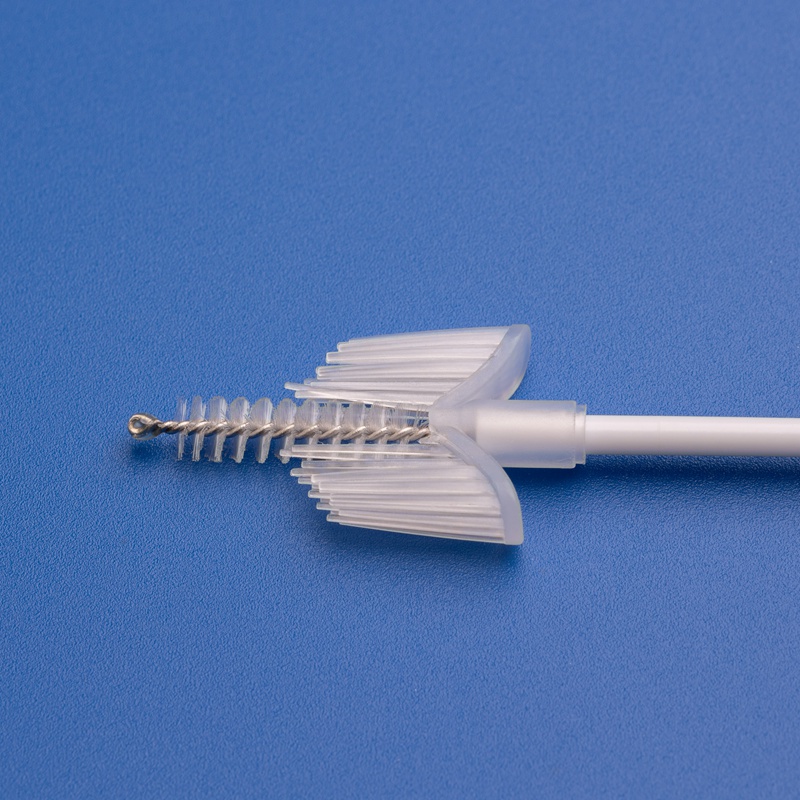

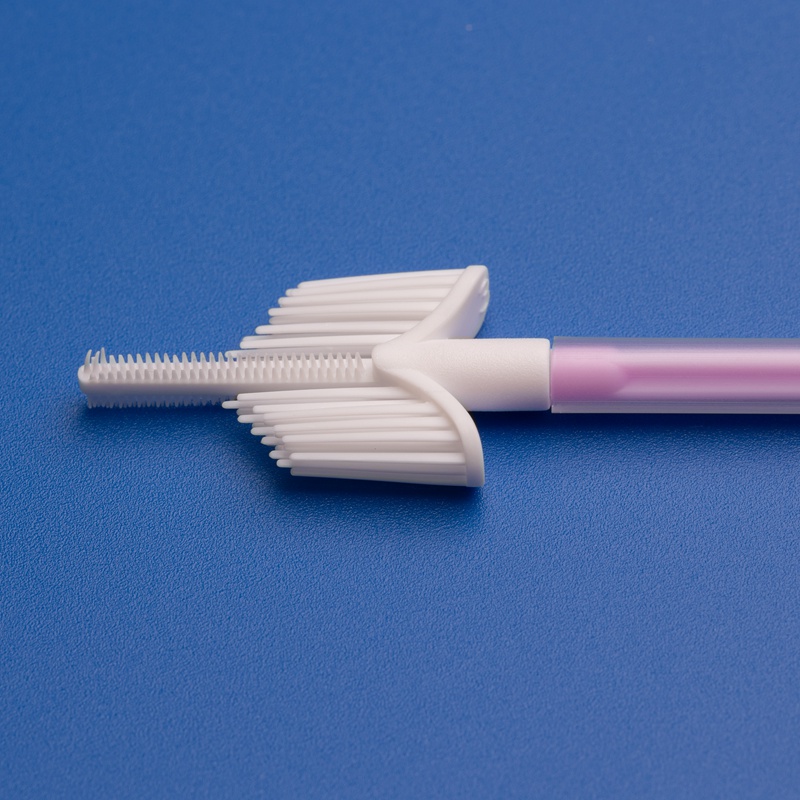

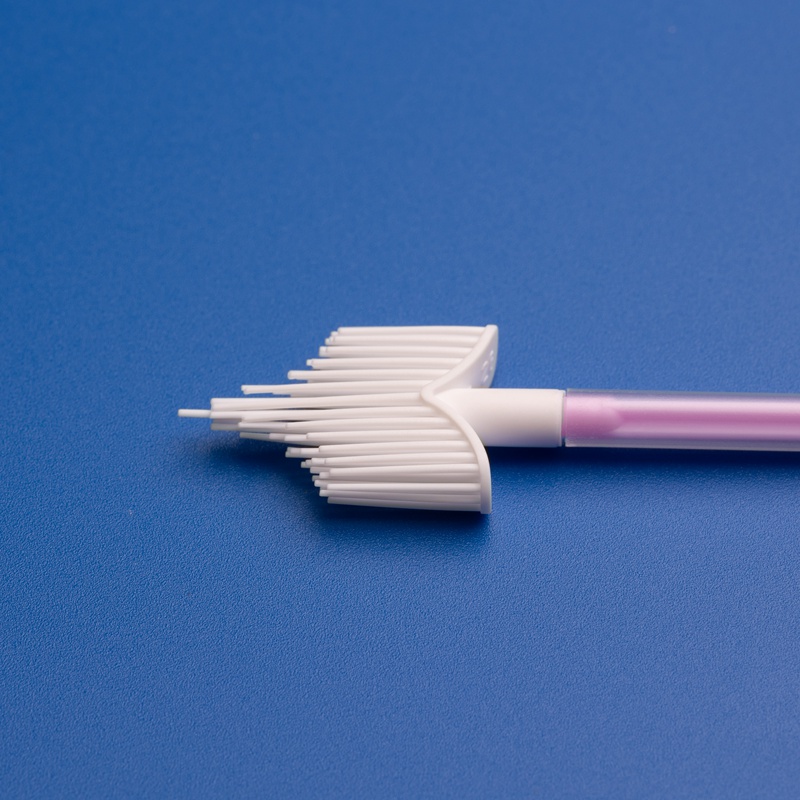

Their comprehensive product portfolio covers essential medical testing consumables, including nasal/throat swabs, disposable cervical sample collectors, sterile cervical brushes, and gynecological scrapers – all produced within their state-of-the-art 10,000㎡ Class 100,000 cleanroom facility.

2. The Global Medical Swab Supply Chain: Why China Leads Manufacturing

The medical swab manufacturing landscape has evolved significantly over the past decade, with China establishing itself as the dominant global producer. Understanding the structure of this supply chain and China’s competitive advantages is essential for wholesale buyers seeking to optimize their procurement strategies.

Global Supply Chain Structure

The medical swab supply chain encompasses several key stages:

Raw Material Sourcing

- Cotton and Synthetic Fibers: Primary materials for swab tips

- Plastics and Polymers: Used for handles and packaging

- Specialized Materials: Including flocked nylon, polyester, and rayon

- Chemical Treatments: Preservatives, buffers, and transport media

Manufacturing and Processing

- Production Facilities: Cleanroom environments for sterile manufacturing

- Quality Control Systems: In-process and finished product testing

- Packaging Operations: Individual wrapping and bulk packaging for distribution

- Sterilization Processes: Gamma irradiation, ethylene oxide, or other methods

Distribution Networks

- Domestic Distributors: Regional suppliers serving local markets

- International Wholesalers: Global distribution of bulk quantities

- Direct B2B Channels: Manufacturer-to-business procurement

- E-commerce Platforms: Online B2B marketplaces facilitating transactions

China’s Competitive Advantages in Medical Swab Production

China has emerged as the world’s leading manufacturer of medical swabs due to several strategic advantages:

Manufacturing Infrastructure

- Scale of Operations: China hosts thousands of medical device manufacturing facilities

- Vertical Integration: Many companies control multiple stages of production

- Advanced Technology: Significant investments in automated production lines

- Production Capacity: Ability to rapidly scale output to meet global demand surges

Cost Efficiency Factors

- Labor Cost Advantages: Despite rising wages, still competitive globally

- Raw Material Proximity: Extensive domestic supply of required materials

- Economies of Scale: High-volume production reducing per-unit costs

- Energy and Utility Efficiencies: Modern facilities designed for optimal resource use

| Cost Factor | China | Western Countries | Other Asian Markets |

|---|---|---|---|

| Labor Costs | Medium-Low | High | Low-Medium |

| Raw Material Access | Excellent | Good | Variable |

| Equipment Costs | Medium | High | Medium-High |

| Regulatory Compliance Costs | Medium | Very High | Medium-Low |

| Overall Production Costs | 60-70% of Western costs | 100% (baseline) | 70-85% of Western costs |

Research and Development Capacity

- Innovation Centers: Specialized medical device R&D hubs in major cities

- Government Investment: Strategic funding for medical technology advancement

- Academic Partnerships: Collaboration with research institutions

- Adaptation Speed: Rapid implementation of design improvements

Leading Chinese manufacturers like Jiangsu Hanheng Medical Technology exemplify this commitment to innovation. Founded in 2018, the company has quickly established itself as an industry leader through its strong R&D capabilities. Their dedicated team continuously explores new technologies and optimizes product designs to stay ahead of evolving requirements in the medical testing field.

Regulatory Environment and Quality Standards

- Improving Regulatory Framework: Strengthened oversight of medical device production

- International Certification Adoption: Widespread implementation of ISO standards

- Export-Focused Quality Systems: Alignment with destination market requirements

- Transparency Initiatives: Enhanced traceability and documentation practices

China’s Market Share and Production Statistics

China’s dominance in medical swab manufacturing is reflected in key statistics:

- Produces approximately 60% of the world’s medical swabs

- Exports to over 180 countries and regions

- Home to more than 3,000 registered medical swab manufacturers

- Annual production capacity exceeding 8 billion units post-COVID expansion

- Export value growing at an average rate of 12% annually since 2018

Post-Pandemic Evolution of China’s Medical Swab Industry

The COVID-19 pandemic triggered unprecedented changes in the medical swab manufacturing landscape:

- Capacity Expansion: Production volumes increased by over 500% during peak demand

- Product Diversification: Development of specialized swabs for different testing protocols

- Supply Chain Resilience: Enhanced domestic sourcing of critical materials

- Quality Control Emphasis: Strengthened testing and verification processes

- Digital Transformation: Implementation of smart manufacturing and traceability systems

These developments have strengthened China’s position as the preeminent global supplier of medical swabs, with companies like Jiangsu Hanheng Medical Technology at the forefront of this evolution. Their 32-acre manufacturing facility featuring a 10,000㎡ Class 100,000 cleanroom exemplifies the scale and quality focus that characterizes China’s leading medical swab producers.

3. Types of Medical Swabs: Materials, Designs & Industry Applications

The medical swab category encompasses a diverse range of products, each designed for specific applications and sampling requirements. For wholesale buyers and distributors, understanding these variations is essential for selecting the right products for their customers’ needs.

Classification by Material Composition

Medical swabs utilize various materials, each offering distinct properties for different clinical applications:

Cotton Swabs

- Composition: 100% natural cotton fibers

- Absorption Capacity: High (80-100μL)

- Applications: General wound cleaning, medication application

- Advantages: Low cost, readily available, biodegradable

- Limitations: Can inhibit PCR reactions, may release fibers

Rayon Swabs

- Composition: Purified cellulose fibers

- Absorption Capacity: Medium (50-80μL)

- Applications: Microbiology, virology, sample collection

- Advantages: Consistent quality, limited PCR inhibition

- Limitations: Lower sample release efficiency than newer materials

Polyester Swabs

- Composition: Synthetic polyester fibers

- Absorption Capacity: Medium-low (40-60μL)

- Applications: Virus and bacteria collection, DNA sampling

- Advantages: Chemical resistance, compatibility with molecular testing

- Limitations: Lower absorption than cotton

Foam Swabs

- Composition: Medical-grade polyurethane foam

- Absorption Capacity: Very high (100-250μL)

- Applications: Wound care, specimen collection from moist sites

- Advantages: High absorption, minimal sample retention

- Limitations: May be too absorbent for certain applications

Flocked Swabs

- Composition: Nylon fibers electrostatically flocked onto handle

- Absorption Capacity: Moderate (50-70μL)

- Applications: Nasopharyngeal sampling, cervical testing, molecular diagnostics

- Advantages: Superior sample collection and release, minimal patient discomfort

- Limitations: Higher cost than traditional fiber swabs

| Material Type | Sample Collection Efficiency | Sample Release Efficiency | Primary Applications |

|---|---|---|---|

| Cotton | Moderate (70-80%) | Low (40-60%) | General cleaning, wound care |

| Rayon | Moderate (75-85%) | Moderate (60-70%) | Microbiology, routine testing |

| Polyester | Good (80-90%) | Good (70-80%) | Molecular diagnostics |

| Foam | Excellent (90-95%) | Good (75-85%) | Wound care, fluid collection |

| Flocked Nylon | Excellent (95-98%) | Excellent (90-95%) | PCR testing, viral collection |

Classification by Design and Structure

The physical design of medical swabs varies significantly based on intended use:

Standard Swabs

- Structure: Fibrous material wrapped around a handle

- Handle Type: Typically wood, plastic, or paper

- Applications: General purpose sampling and cleaning

- Packaging: Often bulk packaging for clinical use

Nasopharyngeal Swabs

- Structure: Thin, flexible shaft with specialized tip

- Handle Type: Flexible plastic or metal with breakpoint

- Applications: Deep nasal cavity sampling for respiratory pathogens

- Packaging: Individual sterile packaging with transport tube

Flocked Swabs

- Structure: Perpendicular nylon fibers precisely arranged

- Handle Type: Plastic, designed for ergonomic handling

- Applications: Respiratory sampling, STI testing, forensic collection

- Packaging: Individual sterile packaging with transport media options

Micro Swabs

- Structure: Miniaturized design for confined spaces

- Handle Type: Thin plastic or metal with precision tip

- Applications: Ophthalmic procedures, pediatric sampling

- Packaging: Ultra-protective sterile packaging

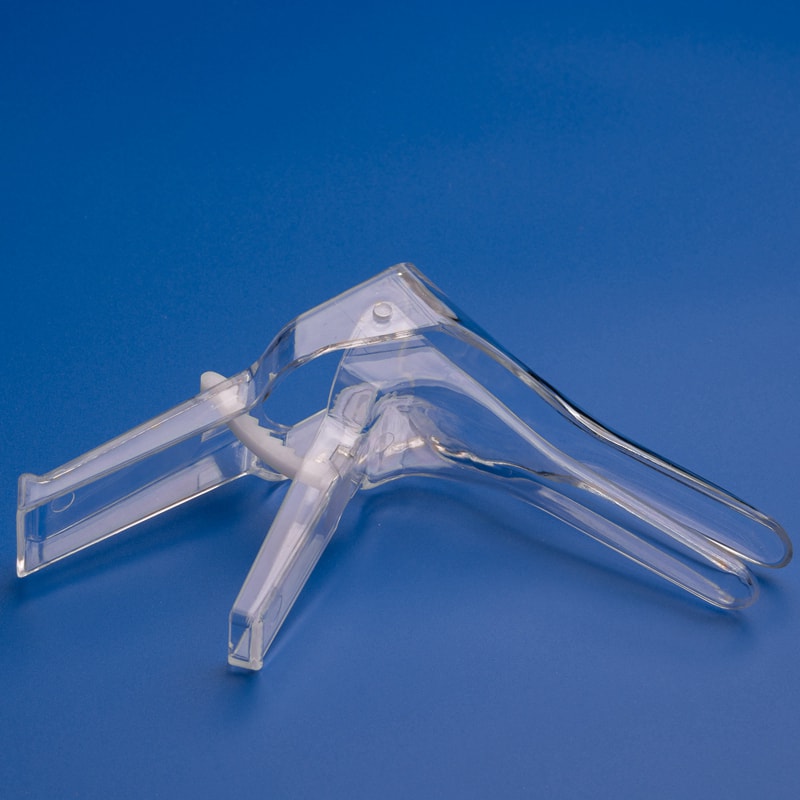

Cervical/Gynecological Swabs

- Structure: Specialized designs for cervical sampling

- Handle Type: Extended plastic with brush or spatula end

- Applications: Pap testing, HPV sampling, gynecological examinations

- Packaging: Sterile packaging with preservation media

Transport Media Swabs

- Structure: Swab integrated with preservation medium

- Handle Type: Plastic with secure tube attachment

- Applications: Microbial sample preservation during transport

- Packaging: Self-contained system with medium-filled tube

Jiangsu Hanheng Medical Technology’s comprehensive product portfolio covers many of these critical variants, including advanced nasal and pharyngeal sampling swabs, disposable cervical sample collectors, sterile cervical brushes, and gynecological scrapers. Their focus on precision manufacturing ensures each product delivers reliability, accuracy, and ease of use in clinical settings.

Specialized Applications Across Healthcare Segments

Different healthcare sectors require specialized swabs for their unique applications:

Clinical Diagnostics

- Respiratory Sampling: Nasopharyngeal and oropharyngeal swabs for influenza, COVID-19, RSV

- Wound Culture: Specialized swabs for collecting bacteria from infected sites

- STI Testing: Urethral, cervical, and vaginal swabs for pathogen detection

- Genetic Testing: DNA collection swabs with preservation capabilities

Surgical and Interventional Procedures

- Pre-operative Skin Preparation: Antiseptic-impregnated swabs

- Intraoperative Use: Sterile swabs for fluid management and visibility

- Post-operative Wound Care: Antimicrobial swabs for infection prevention

- Vascular Access: Specialized swabs for catheter site cleaning

Research and Laboratory Applications

- Genomic Studies: Low-DNA binding swabs for sample collection

- Cell Culture: Sterile swabs for controlled environmental monitoring

- Protein Analysis: Specialized swabs minimizing protein interference

- Environmental Monitoring: Swabs designed for surface sampling

Pharmaceutical and Manufacturing Quality Control

- Surface Sampling: Validated swabs for cleanroom monitoring

- Bioburden Testing: Specialized swabs for microbial detection

- Residue Analysis: Swabs designed for chemical residue collection

- Sterility Testing: Highly controlled swabs for aseptic processing verification

Emerging Innovations in Medical Swab Technology

The medical swab industry continues to evolve with several notable innovations:

- Self-Sampling Designs: Ergonomic swabs designed for patient self-collection

- Rapid-Result Indicators: Color-changing tips indicating successful sample collection

- Preservation Technologies: Advanced media extending sample viability

- Antimicrobial Materials: Swabs incorporating infection-resistant properties

- Biodegradable Options: Environmentally friendly alternatives to traditional plastics

Jiangsu Hanheng Medical Technology exemplifies this commitment to innovation, with their R&D team continuously exploring new technologies and optimizing product performance. By leveraging advanced materials and manufacturing methods, they ensure their swabs provide the reliability and precision demanded by modern healthcare applications.

Let me continue with the next three sections:

4. Selecting a Reliable Medical Swab Manufacturer in China

For B2B buyers, distributors, and healthcare suppliers, finding the right manufacturing partner in China is a crucial decision that impacts product quality, supply chain reliability, and ultimately, end-user satisfaction. This section outlines the key considerations and evaluation criteria for selecting a trustworthy medical swab manufacturer.

Essential Qualification Criteria

When assessing potential manufacturing partners, wholesale buyers should prioritize the following qualification factors:

Regulatory Compliance and Certifications

- ISO Certifications: ISO 13485 (medical devices) and ISO 9001 (quality management) are foundational requirements

- FDA Registration: Verification of registration with the U.S. Food and Drug Administration for exported products

- CE Marking: Compliance with European Union safety standards

- NMPA Approval: China’s National Medical Products Administration licensing

- Additional Certifications: MDSAP (Medical Device Single Audit Program), CMDCAS (Canadian requirements)

Jiangsu Hanheng Medical Technology exemplifies these standards, maintaining rigorous compliance with international quality requirements. The company has obtained ISO9001 and ISO13485 certifications, EU CE certification, and US FDA approval, validating their commitment to meeting global regulatory standards.

| Certification | Importance | Verification Method |

|---|---|---|

| ISO 13485 | Essential | Certificate verification through ISO database |

| FDA Registration | Essential for US market | Search FDA database for registration number |

| CE Mark | Essential for EU market | Certificate verification through notified body |

| NMPA License | Essential for legitimacy | Chinese regulatory database verification |

| ISO 9001 | Highly recommended | Certificate verification through ISO database |

Manufacturing Capabilities Assessment

- Production Capacity: Ability to meet volume requirements and scale with demand

- Facility Specifications: Cleanroom classification, environmental controls, and contamination prevention

- Equipment Technology: Automation level, precision manufacturing capabilities

- Quality Control Systems: In-process inspection protocols, testing equipment, and sampling methods

- Sterilization Capabilities: Validated sterilization processes and verification methods

Jiangsu Hanheng demonstrates exceptional manufacturing capabilities with their state-of-the-art 32-acre facility featuring a 10,000㎡ Class 100,000 cleanroom. This advanced manufacturing environment ensures strict compliance with international production standards, supporting high-volume production while maintaining quality consistency.

Quality Assurance Practices

- Material Sourcing Controls: Supplier qualification programs and material verification

- Validation Protocols: Process validation documentation and ongoing verification

- Batch Testing Standards: Sampling procedures and acceptance criteria

- Traceability Systems: Lot tracking capabilities from raw materials to finished goods

- Non-conformance Management: Procedures for handling quality deviations

- Stability Testing: Shelf life validation and ongoing stability monitoring

Technical Expertise and Innovation Capabilities

- R&D Investment: Dedicated research staff and development programs

- Engineering Capabilities: Product design expertise and modification abilities

- Material Science Knowledge: Understanding of biomaterial interactions and performance

- Technical Documentation: Comprehensive product specifications and testing data

- Problem-Solving Record: History of addressing technical challenges and improvements

Jiangsu Hanheng’s dedication to innovation is evident in their strong R&D team, which continuously explores new technologies and optimizes product performance. Their comprehensive approach to R&D spans the entire product lifecycle, ensuring consistent advancement in medical swab design and functionality.

Due Diligence Process for Manufacturer Selection

Implementing a systematic evaluation process helps ensure selection of the right manufacturing partner:

Preliminary Screening

- Company Background Investigation: Years in business, ownership structure, financial stability

- Product Portfolio Analysis: Alignment with required product types and specifications

- Certification Verification: Validation of claimed certifications through official channels

- Manufacturing Scale Assessment: Production capacity relative to anticipated demand

- Market Reputation Research: Industry references and existing customer feedback

In-Depth Evaluation

- Technical Capability Assessment: Detailed review of manufacturing processes and technologies

- Quality System Audit: Comprehensive evaluation of quality management systems

- Sample Evaluation: Testing of product samples against performance specifications

- Facility Inspection: On-site or virtual assessment of manufacturing conditions

- Supply Chain Analysis: Evaluation of raw material sourcing and inventory management

- Regulatory Compliance Verification: Detailed review of documentation and compliance history

Final Selection Considerations

- Communication Capabilities: English proficiency and responsiveness

- Business Terms Flexibility: Willingness to accommodate special requirements

- Intellectual Property Protection: Confidentiality practices and agreements

- Pricing Structure Transparency: Clear cost breakdowns and volume pricing

- Geographic Location: Proximity to shipping hubs and transportation infrastructure

Avoiding Common Pitfalls in Manufacturer Selection

B2B buyers should be vigilant about these frequent challenges:

- Certification Misrepresentation: Verifying authenticity of claimed certifications

- Capability Overstatement: Confirming actual production capacity matches claims

- Quality Inconsistency: Establishing robust quality agreements with clear specifications

- Hidden Costs: Ensuring comprehensive understanding of all costs beyond unit pricing

- Intellectual Property Risks: Implementing adequate protection measures and agreements

Building Strategic Manufacturer Relationships

For long-term success, wholesale buyers should focus on developing strategic partnerships:

- Collaborative Product Development: Joint innovation initiatives to address market needs

- Transparent Communication Channels: Established points of contact and regular updates

- Performance Metrics Alignment: Shared understanding of quality and delivery expectations

- Continuous Improvement Programs: Collaborative efforts to enhance products and processes

- Long-term Agreement Structures: Framework agreements balancing stability and flexibility

When evaluating potential partners like Jiangsu Hanheng Medical Technology, their established track record since 2018 demonstrates stability and commitment to the medical consumables industry. Their comprehensive approach to manufacturing excellence, from cleanroom facilities to advanced R&D capabilities, positions them as an ideal strategic partner for wholesale buyers seeking reliable medical swab suppliers.

5. Private Labeling & Customization Options for Medical Swabs

For wholesale buyers and distributors looking to establish market differentiation, private labeling and customization options present significant opportunities to build brand equity and address specific market needs. This section explores the range of customization possibilities available from Chinese medical swab manufacturers and the strategic advantages they offer.

Private Labeling Fundamentals for Medical Swabs

Private labeling enables wholesale buyers to market products under their own brand while leveraging the manufacturing expertise of established producers. This approach offers several strategic advantages:

Core Benefits of Private Labeling

- Brand Development: Building proprietary brand recognition in target markets

- Margin Enhancement: Potential for higher profit margins compared to reselling existing brands

- Market Differentiation: Creating unique positioning separate from competitors

- Distribution Control: Greater influence over pricing and distribution channels

- Customer Loyalty: Developing direct relationships with end-users rather than promoting third-party brands

Private Labeling Tiers Available from Chinese Manufacturers

Most Chinese medical swab manufacturers, including Jiangsu Hanheng Medical Technology, offer multiple levels of private labeling services:

| Private Labeling Tier | Customization Elements | Minimum Order Quantity | Lead Time | Cost Impact |

|---|---|---|---|---|

| Basic Branding | Outer packaging only | 10,000-25,000 units | 15-30 days | +5-10% |

| Standard Private Label | Packaging + basic product labeling | 25,000-50,000 units | 30-45 days | +10-15% |

| Premium Branding | Comprehensive branding across all elements | 50,000+ units | 45-60 days | +15-25% |

| Full Customization | Custom design, materials, and branded packaging | 100,000+ units | 60-90 days | +25-40% |

Jiangsu Hanheng Medical Technology offers comprehensive private labeling services across their product range, accommodating various customization requirements while maintaining strict adherence to quality and regulatory standards.

Product Customization Possibilities

Beyond basic branding, medical swab manufacturers can modify product specifications to meet specific requirements:

Physical Design Customization

- Handle Length and Material: Custom dimensions and material selection for specific applications

- Tip Size and Shape: Modified tip designs for specialized sampling procedures

- Shaft Flexibility: Adjusted rigidity based on anatomical collection requirements

- Breaking Points: Custom designed break points for sample processing

- Ergonomic Features: Enhanced grip designs or handling features

Material and Performance Modifications

- Absorption Capacity: Adjusted to meet specific sample volume requirements

- Fiber Density: Modified for particular collection efficiency needs

- Material Selection: Custom material combinations for specialized applications

- Specialized Coatings: Hydrophilic or hydrophobic treatments for certain tests

- Release Efficiency: Enhanced sample release properties for laboratory processing

Packaging Customization Options

- Individual Wrapping Design: Custom printed sterile packages with brand elements

- Bulk Packaging Configuration: Specialized box designs and unit quantities

- Transport Media Integration: Custom media formulations for specific test requirements

- Convenience Features: Peel points, opening mechanisms, and usability enhancements

- Information Content: Custom instructions, lot tracking, and regulatory information

Jiangsu Hanheng’s flexibility in customization allows wholesale buyers to create precisely tailored products for their target markets. Their advanced manufacturing capabilities ensure that customized products maintain the same level of quality and regulatory compliance as standard offerings.

The Customization Process: From Concept to Production

Successful customization projects follow a structured development process:

Initial Consultation and Requirements Definition

- Application Specification: Defining the intended use and performance requirements

- Target Market Analysis: Identifying regulatory requirements for destination markets

- Volume Projections: Establishing anticipated order volumes and production needs

- Design Brief Development: Documenting specific customization requirements

- Feasibility Assessment: Manufacturer evaluation of technical and regulatory viability

Design and Prototyping Phase

- Preliminary Designs: Development of initial design concepts and specifications

- Material Selection: Identification of appropriate materials meeting requirements

- Prototype Development: Creation of sample products for evaluation

- Performance Testing: Validation of prototype functionality against specifications

- Design Refinement: Adjustments based on testing results and feedback

Regulatory Compliance Planning

- Regulatory Pathway Identification: Determining necessary approvals for customized products

- Testing Requirements Definition: Establishing required validation and verification tests

- Documentation Preparation: Developing technical files and regulatory submissions

- Compliance Strategy: Planning for market-specific regulatory requirements

- Risk Management: Identifying and mitigating potential compliance challenges

Production Implementation

- Manufacturing Process Validation: Ensuring consistent production of customized design

- Quality Control Protocol Development: Establishing inspection criteria for custom features

- Pilot Production Run: Limited production to validate manufacturing processes

- Scale-up Planning: Transition strategy from pilot to full-scale production

- Final Specification Documentation: Comprehensive documentation of all custom elements

Working with an experienced manufacturer like Jiangsu Hanheng Medical Technology streamlines this process, as their R&D team can provide valuable guidance on feasibility, material selection, and regulatory considerations while developing custom solutions.

Strategic Considerations for Private Labeling and Customization

Wholesale buyers should consider these factors when pursuing private labeled or customized medical swabs:

Cost-Benefit Analysis

- Price Premium Potential: Market research on acceptable price differentials for branded products

- Volume Requirements: Balancing customization costs against order quantities

- Setup Investment: Initial costs for design, tooling, and regulatory approval

- Inventory Management: Carrying costs for custom product inventories

- Long-term Value Assessment: Brand equity development versus immediate margin impact

Market Differentiation Strategy

- Competitive Analysis: Identifying gaps in market offerings that customization can address

- Value Proposition Development: Defining how custom features deliver enhanced value

- Target Segment Identification: Determining which market segments value specific customizations

- Pricing Strategy Alignment: Ensuring customization supports overall pricing approach

- Market Positioning: Using private labeling to establish specific market positioning

Quality Assurance for Custom Products

- Specification Documentation: Detailed documentation of all custom requirements

- Quality Agreement Development: Clear definition of acceptance criteria and testing methods

- Consistency Verification: Processes for ensuring batch-to-batch consistency

- Change Control Protocols: Procedures for managing any future modifications

- Complaint Handling Systems: Specialized tracking for any issues with custom features

By partnering with Jiangsu Hanheng Medical Technology, wholesale buyers gain access to comprehensive customization capabilities backed by strong quality systems and regulatory expertise. Their commitment to innovation and customer-focused development ensures that private label projects deliver products that precisely meet market requirements while maintaining the highest standards of quality and compliance.

6. Quality Certifications & Regulatory Compliance for Medical Swab Exports

For wholesale buyers and distributors, understanding the complex landscape of quality certifications and regulatory requirements is essential when sourcing medical swabs from China. This section outlines the key standards, compliance pathways, and verification processes that ensure product safety, performance, and market access.

Global Regulatory Framework for Medical Swabs

Medical swabs are classified as medical devices in most regulatory systems, with classification levels varying based on intended use and associated risk:

Key Regulatory Classifications

- United States (FDA): Class I (general controls) or Class II (special controls) depending on intended use

- European Union (MDR): Class I, Is (sterile), Im (measuring function), or IIa depending on application

- China (NMPA): Class I or Class II based on risk profile and intended use

- Canada (Health Canada): Class I or Class II depending on specific application

- Japan (PMDA): Class I or Class II based on risk assessment

Regulatory Requirements by Major Market

| Market | Primary Regulation | Required Documentation | Registration Process | Labeling Requirements |

|---|---|---|---|---|

| United States | FDA 21 CFR 820 | 510(k) or exempt registration | FDA listing and registration | English labeling with specific elements |

| European Union | MDR 2017/745 | Technical File/Design Dossier | CE marking through Notified Body or self-declaration | Multi-language with specific symbols |

| China | Order 739 and 680 | Technical Requirements for Registration | NMPA registration | Chinese labeling with registration information |

| Canada | Medical Devices Regulations | Medical Device License application | Health Canada review | Bilingual labeling (English/French) |

| Australia | Therapeutic Goods Act | ARTG inclusion application | TGA assessment | English labeling with ARTG number |

Essential Quality Management System Certifications

Legitimate medical swab manufacturers must maintain certified quality management systems adhering to international standards:

ISO 13485 Medical Devices Quality Management System

- Scope: Comprehensive quality system specifically for medical device manufacturing

- Verification Method: Certificate issued by accredited certification body

- Renewal Requirement: Annual surveillance audits with recertification every three years

- Critical Elements: Document control, risk management, design controls, process validation

- Importance: Fundamental requirement for all reputable medical device manufacturers

ISO 9001 Quality Management System

- Scope: General quality management principles applicable across industries

- Relationship to Medical Devices: Often maintained alongside ISO 13485

- Key Focus Areas: Process approach, evidence-based decision making, customer focus

- Verification: Certificate from accredited certification body

- Value to Buyers: Demonstrates commitment to overall quality management principles

Jiangsu Hanheng Medical Technology maintains both ISO 13485 and ISO 9001 certifications, demonstrating their comprehensive approach to quality management and regulatory compliance. These certifications validate their adherence to international best practices in medical device manufacturing.

Market-Specific Approvals and Certifications

Different global markets require specific approvals for medical swab importation and distribution:

United States Market Entry Requirements

- FDA Registration and Listing: Mandatory registration of manufacturing facility

- 510(k) Clearance: Required for certain swab types depending on intended use

- Quality System Regulation Compliance: Adherence to 21 CFR 820

- Labeling Requirements: Compliance with specific FDA labeling regulations

- Unique Device Identification (UDI): Implementation of UDI system for traceability

European Union Requirements

- CE Marking: Essential for market access, based on conformity assessment

- EU Authorized Representative: Mandatory for non-EU manufacturers

- Technical Documentation: Comprehensive technical file meeting MDR requirements

- Post-Market Surveillance System: Ongoing monitoring and reporting system

- EUDAMED Registration: Registration in European database for medical devices

Other Major Market Requirements

- China NMPA Registration: Required for domestic sale and distribution

- Japan PMDA Approval: Foreign manufacturer registration and product approval

- Brazil ANVISA Registration: Product registration through Brazilian regulatory system

- Russia Roszdravnadzor Registration: Medical device registration certificate

- South Korea MFDS Approval: Medical device approval for Korean market

Jiangsu Hanheng Medical Technology’s products carry EU CE certification and US FDA approval, demonstrating their commitment to meeting the regulatory requirements of major global markets. This comprehensive regulatory compliance makes them an ideal partner for wholesale buyers seeking products ready for international distribution.

Product-Specific Testing and Standards

Medical swabs must meet various performance and safety standards depending on their intended use:

Biocompatibility Testing (ISO 10993 Series)

- Cytotoxicity Testing: Evaluation of potential toxic effects on cells

- Sensitization Testing: Assessment of allergic reaction potential

- Irritation Testing: Evaluation of potential to cause irritation

- Systemic Toxicity: Testing for broader systemic effects

- Documentation Requirements: Full biocompatibility assessment reports

Performance Testing Standards

- Absorption Capacity: Standardized testing of fluid uptake capabilities

- Material Strength: Evaluation of shaft integrity and break resistance

- Fiber Release: Testing for potential shedding of fibers during use

- Sample Collection Efficiency: Validation of collection and release performance

- Compatibility with Assays: Verification of non-interference with test methods

Sterilization Validation

- Sterilization Methods: Validation of ethylene oxide, radiation, or other processes

- Sterility Assurance Level (SAL): Typically 10^-6 for sterile medical swabs

- Residual Testing: Analysis of potential sterilization process residuals

- Packaging Integrity: Validation of sterile barrier maintenance

- Shelf Life Verification: Stability testing to support expiration dating

Verification and Due Diligence for Buyers

Wholesale buyers should implement systematic verification processes when assessing manufacturer compliance:

Document Authentication Procedures

- Certificate Verification: Validation through issuing certification bodies

- FDA Registration Confirmation: Searching FDA database for registration numbers

- CE Mark Verification: Checking validity through Notified Body registers

- Test Report Authentication: Confirming legitimacy of test laboratories

- Declaration of Conformity Validation: Verifying against referenced standards

On-site Audit Components

- Quality Management System Review: Evaluation of QMS implementation

- Production Environment Assessment: Cleanroom classification verification

- Process Controls Examination: Review of critical manufacturing controls

- Testing Capabilities Evaluation: Assessment of in-process and final testing

- Document Control Systems: Verification of documentation practices

Supply Chain Security Measures

- Material Traceability Verification: Confirmation of raw material tracking

- Supplier Management Assessment: Review of supplier qualification process

- Change Control Procedures: Evaluation of change management systems

- Complaint Handling Systems: Assessment of post-market surveillance

- Corrective Action Processes: Review of issue resolution procedures

Working with established manufacturers like Jiangsu Hanheng Medical Technology significantly reduces compliance risks for wholesale buyers. Their comprehensive quality systems, documented regulatory approvals, and transparent verification processes provide assurance that their medical swabs meet all relevant standards and requirements.

Let me finish with the last three sections:

7. Cost Analysis: Pricing Factors for Wholesale Medical Swab Procurement

For wholesale buyers, distributors, and healthcare suppliers, understanding the complex cost structure of medical swabs is essential for effective procurement strategy and margin management. This section provides a detailed analysis of the factors influencing pricing, cost optimization strategies, and volume-based pricing considerations.

Primary Cost Components in Medical Swab Manufacturing

The pricing structure for medical swabs incorporates several key cost elements:

Raw Material Costs

- Base Materials: Cotton, rayon, polyester, nylon, or foam materials for swab tips

- Handle Materials: Medical-grade plastics, wood, or specialized polymers

- Packaging Materials: Sterile pouches, transport media components, bulk packaging

- Material Quality Tiers: Standard vs. premium material options with price differentials

- Market Fluctuations: Commodity price variations affecting cost stability

Production Process Costs

- Labor Expenses: Direct manufacturing labor and specialized technical staff

- Equipment Depreciation: Amortization of automated manufacturing equipment

- Cleanroom Operations: Maintenance of controlled manufacturing environments

- Quality Control Processes: In-process and finished product testing expenses

- Sterilization Processes: Ethylene oxide, gamma irradiation, or other sterilization methods

Regulatory Compliance Costs

- Quality System Maintenance: Ongoing expenses for maintaining certified quality systems

- Testing and Validation: Product and process validation expenses

- Regulatory Submissions: Costs for obtaining and maintaining market approvals

- Audit Preparations: Resources dedicated to regulatory and customer audits

- Documentation Management: Maintenance of technical files and compliance records

| Cost Component | Percentage of Total Cost | Variation Factors | Cost Control Options |

|---|---|---|---|

| Raw Materials | 30-40% | Material quality, market prices, order volume | Volume commitments, material standardization |

| Direct Labor | 15-25% | Production location, automation level | Process optimization, automation investment |

| Packaging | 10-15% | Complexity, sterility requirements | Standardized packaging, volume efficiency |

| Sterilization | 5-10% | Method selected, batch size | Batch optimization, method selection |

| Quality Assurance | 8-12% | Testing requirements, rejection rates | Process improvements, supplier qualification |

| Regulatory Compliance | 5-8% | Target markets, product classification | Market focus, regulatory strategy |

| Overhead & Profit | 15-25% | Manufacturer size, company positioning | Volume commitments, long-term partnerships |

Price Variation Factors Across Different Swab Types

Different swab types and specifications command varying price points:

Standard Cotton Swabs

- Typical Wholesale Price Range: $0.02-0.05 per unit (non-sterile)

- Sterile Version Premium: +50-100% over non-sterile

- Volume Discount Potential: 15-30% at high volumes

- Key Cost Drivers: Cotton quality, handle material, packaging type

Specialized Flocked Swabs

- Typical Wholesale Price Range: $0.15-0.40 per unit

- Customization Premium: +10-30% for specialized designs

- Volume Discount Potential: 10-25% at high volumes

- Key Cost Drivers: Flocking process complexity, fiber quality, handle design

Transport Media Swabs

- Typical Wholesale Price Range: $0.30-0.80 per unit

- Media Formulation Impact: Specialized media can increase costs by 15-40%

- Volume Discount Potential: 10-20% at high volumes

- Key Cost Drivers: Media composition, tube design, preservation effectiveness

Specialized Gynecological Swabs

- Typical Wholesale Price Range: $0.25-0.70 per unit

- Design Complexity Impact: Specialized shapes add 10-30% to base cost

- Volume Discount Potential: 10-25% at high volumes

- Key Cost Drivers: Material selection, design precision, quality requirements

As a leading manufacturer of comprehensive medical testing consumables, Jiangsu Hanheng Medical Technology offers competitive pricing across their extensive product range while maintaining strict quality standards. Their manufacturing scale and efficiency allow them to provide attractive pricing for wholesale buyers while delivering products that meet international quality requirements.

Volume-Based Pricing Strategies

Wholesale buyers can optimize costs through strategic volume management:

Typical Volume Discount Tiers

- Standard Volume (5,000-10,000 units): Base wholesale pricing

- Medium Volume (10,000-50,000 units): 5-15% discount from base

- High Volume (50,000-100,000 units): 15-25% discount from base

- Contract Volume (100,000+ units): 25-40% discount with commitment

Long-Term Agreement Benefits

- Price Stability Guarantees: Protection from short-term material cost fluctuations

- Reserved Capacity Advantages: Priority production scheduling and capacity allocation

- Scheduled Delivery Programs: Optimized logistics and inventory management

- Collaborative Forecasting Benefits: Improved planning and resource allocation

- Development Priority: Preferential access to new product innovations

Minimum Order Quantity Considerations

- Standard Catalog Products: Typically 5,000-10,000 units minimum

- Custom Color or Printing: Often 10,000-25,000 units minimum

- Custom Design Modifications: Usually 25,000-50,000 units minimum

- Fully Custom Products: Generally 50,000+ units minimum

- MOQ Negotiation Factors: Total business volume, product complexity, market potential

Total Cost of Ownership Analysis

Beyond unit pricing, wholesale buyers should consider the comprehensive cost impact:

Quality-Related Cost Factors

- Defect Rate Implications: Higher quality reduces returns and replacement costs

- Consistency Benefits: Uniform products improve user efficiency and reduce waste

- Performance Reliability: Better sample collection reduces repeat testing needs

- End-User Satisfaction: Quality impacts customer retention and brand reputation

- Regulatory Compliance Assurance: Lower risk of regulatory issues and recalls

Supply Chain Cost Considerations

- Lead Time Factors: Inventory carrying costs vs. production lead time

- Shipping Consolidation Opportunities: Full container vs. partial shipments

- Import Duty Optimization: Classification strategies and trade agreement benefits

- Payment Terms Impact: Cash flow effects of different payment structures

- Documentation Requirements: Administrative costs of import/export compliance

Hidden Cost Avoidance

- Quality System Compatibility: Reduced supplier qualification and audit costs

- Technical Support Value: Manufacturer expertise reducing internal resource needs

- Complaint Investigation Efficiency: Responsive manufacturer support for issues

- Regulatory Documentation Readiness: Complete technical files reducing compliance workload

- Supply Continuity Assurance: Reliability reducing emergency sourcing expenses

Jiangsu Hanheng Medical Technology’s comprehensive approach to quality, with ISO9001 and ISO13485 certifications, helps wholesale buyers reduce these hidden costs while maintaining competitive unit pricing. Their established manufacturing capacity across their 32-acre facility ensures reliable supply and consistent quality, optimizing the total cost of ownership for wholesale buyers.

Negotiation Strategies for Wholesale Buyers

Effective negotiation requires understanding of manufacturer cost structures and priorities:

Value-Added Negotiation Approaches

- Volume Commitment Strategies: Guaranteed quantities in exchange for pricing concessions

- Forecasting Transparency Benefits: Sharing projected demand to improve planning

- Payment Term Flexibility: Optimizing cash flow for both parties

- Exclusivity Arrangements: Territory or market exclusivity in exchange for volume commitment

- Joint Marketing Opportunities: Collaborative promotion reducing marketing costs

Technical Specification Optimization

- Material Standardization: Aligning specifications with manufacturing efficiencies

- Packaging Rationalization: Optimizing packaging for cost efficiency

- Quality Requirement Calibration: Aligning specifications with actual needs

- Order Frequency Planning: Scheduling to optimize production efficiency

- Specification Flexibility: Allowing non-critical parameter variations for efficiency

Strategic Relationship Development

- Multi-Product Bundling: Consolidating purchasing across product categories

- New Product Development Collaboration: Joint development reducing R&D costs

- Market Intelligence Sharing: Exchanging non-competitive market insights

- Continuous Improvement Initiatives: Collaborative cost reduction programs

- Logistics Coordination: Optimizing shipping and delivery schedules

8. Shipping & Logistics: Importing Medical Swabs from China

The efficiency and reliability of the logistics process are critical factors in successful medical swab importation from China. This section provides wholesale buyers with comprehensive guidance on shipping methods, documentation requirements, customs procedures, and inventory management strategies.

International Shipping Options from China

Multiple shipping methods are available, each with distinct considerations for medical swab importation:

Air Freight

- Transit Time: 3-7 days to most global destinations

- Cost Structure: $4-8 per kg depending on volume and destination

- Minimum Requirements: Economically viable for 100+ kg shipments

- Advantages: Rapid delivery, reduced transit inventory, less packaging required

- Limitations: Higher cost per unit, capacity constraints during peak seasons

Ocean Freight

- Transit Time: 15-45 days depending on destination

- Cost Structure:

- FCL (Full Container Load): $2,000-4,500 for 20′ container

- LCL (Less than Container Load): $30-60 per cubic meter plus base charges

- Minimum Requirements: LCL viable from 2 cubic meters upward

- Advantages: Cost-effective for larger volumes, predictable scheduling

- Limitations: Extended transit time, greater inventory planning required

Express Courier Services

- Transit Time: 2-5 days to most global destinations

- Cost Structure: $15-25 per kg with declining rates for higher weights

- Practical Limits: Most economical for shipments under 300 kg

- Advantages: Door-to-door service, simplified documentation, online tracking

- Limitations: Premium pricing, dimensional weight charges, size restrictions

| Shipping Method | Best For | Cost Efficiency | Transit Time | Documentation Complexity |

|---|---|---|---|---|

| Air Freight | Urgent medium volumes | Medium | Fast (3-7 days) | Moderate |

| Ocean FCL | Large volume regular orders | High for large shipments | Slow (20-45 days) | High |

| Ocean LCL | Medium volume regular orders | Medium | Slow (25-50 days) | High |

| Express Courier | Samples, urgent small orders | Low | Very Fast (2-5 days) | Low |

| Rail Freight (China-Europe) | Non-urgent medium volumes | Medium-High | Medium (12-20 days) | Moderate |

Documentation and Compliance Requirements

Proper documentation is essential for smooth customs clearance of medical swabs:

Essential Shipping Documents

- Commercial Invoice: Detailed product description, quantities, values

- Packing List: Itemized contents with dimensions and weights

- Bill of Lading/Airway Bill: Transport contract with carrier

- Certificate of Origin: Verification of manufacturing country

- Customs Declaration Forms: Country-specific import documentation

Medical Device-Specific Documentation

- Product Registration Certificates: Market-specific regulatory approvals

- Quality Certificates: ISO certifications, test reports, quality assurances

- Declaration of Conformity: Manufacturer’s compliance declaration

- Free Sale Certificate: Confirmation of legal sale in country of origin

- Safety Data Sheets: For products with specific material requirements

Import License Requirements

- Medical Device Import License: Required in many countries for medical swabs

- Registration Verification: Confirmation of product registration in destination market

- Importer of Record Documentation: Legal responsibility designation

- End-User Certificates: For products with restricted applications

- Special Permit Requirements: Country-specific authorization documents

Jiangsu Hanheng Medical Technology provides comprehensive documentation support for their products, helping wholesale buyers navigate complex import requirements. Their experience with international shipping ensures that all necessary certificates and declarations are properly prepared, reducing customs delays and compliance risks.

Customs Clearance Procedures

Effective management of customs processes is critical for timely receipt of medical swab shipments:

Harmonized System (HS) Code Classification

- Primary Medical Swab HS Codes:

- 3005.90: Wadding, gauze, bandages and similar articles

- 9018.90: Medical instruments and appliances

- 3822.00: Diagnostic or laboratory reagents (for transport media swabs)

- Classification Considerations: Intended use, material composition, sterility

- Misclassification Risks: Incorrect duties, clearance delays, potential penalties

Import Duty and Tax Considerations

- Duty Rate Determinants: Product classification, country of origin, trade agreements

- Value-Added Tax Application: Country-specific VAT or sales tax requirements

- Duty Exemption Possibilities: Medical necessity provisions, temporary COVID measures

- Special Trade Agreement Benefits: Reduced or eliminated duties under specific agreements

- Advance Ruling Options: Pre-shipment classification confirmation

Customs Broker Selection

- Expertise Requirements: Experience with medical device imports

- Service Level Evaluation: Responsiveness, documentation handling, problem resolution

- Cost Structure Assessment: Fee transparency, additional service charges

- Technology Integration: Electronic documentation capabilities, tracking systems

- Network Strength: Presence at key ports of entry, international partnerships

Inventory Management Strategies for Long Lead Times

China-sourced medical swabs require strategic inventory planning due to extended supply chains:

Forecast-Based Inventory Models

- Safety Stock Calculation: Buffer inventory based on lead time variability

- Reorder Point Determination: Trigger levels accounting for transit time

- Demand Variability Assessment: Flexibility for seasonal or market fluctuations

- ABC Classification: Prioritizing critical vs. standard items

- Economic Order Quantity Calculation: Balancing ordering and holding costs

Staged Shipping Approaches

- Initial Air Shipment: Expedited partial shipment to maintain supply

- Follow-on Ocean Freight: Bulk shipment via more economical method

- Hybrid Strategies: Concurrent shipping via multiple methods

- Critical Timing Coordination: Alignment with demand peaks and marketing initiatives

- Port Diversification: Utilizing multiple entry points for risk mitigation

Inventory Financing Considerations

- Payment Term Optimization: Balancing cash flow with inventory availability

- Trade Finance Instruments: Letters of credit, documentary collections

- Inventory Holding Cost Calculation: True cost accounting for extended supply chains

- Currency Exchange Management: Hedging strategies for large orders

- Import Financing Programs: Utilizing specialized import financing solutions

Risk Management in International Shipping

Proactive risk management helps protect medical swab supply continuity:

Supply Chain Disruption Mitigation

- Multi-Sourcing Strategies: Secondary supplier relationships

- Port Congestion Contingency Plans: Alternative routing options

- Carrier Diversification: Relationships with multiple shipping lines

- Buffer Stock Maintenance: Strategic reserves for disruption periods

- Shipment Visibility Systems: Real-time tracking and proactive alerts

Quality Preservation During Transit

- Temperature Monitoring: For temperature-sensitive products

- Humidity Control Measures: Moisture barrier packaging for sensitive items

- Physical Protection Standards: Impact-resistant packaging requirements

- Sterility Maintenance Validation: Ensuring sterile barrier integrity

- Shelf Life Considerations: Transit time impact on effective product life

Insurance and Liability Protection

- Cargo Insurance Coverage: Appropriate valuation and risk coverage

- Liability Delineation: Clear terms for risk transfer points

- Claims Process Preparation: Documentation requirements for potential claims

- High-Value Shipment Protocols: Enhanced security for premium products

- Compliance Documentation: Records supporting regulatory adherence

Working with established manufacturers like Jiangsu Hanheng Medical Technology provides wholesale buyers with experienced logistics support and risk management expertise. Their understanding of international shipping requirements for medical consumables helps ensure smooth importation and supply chain reliability.

9. FAQs for Wholesale Medical Swab Buyers

This section addresses the most common questions wholesale buyers, distributors, and healthcare suppliers have when sourcing medical swabs from Chinese manufacturers. These insights help clarify key considerations, address misconceptions, and provide practical guidance for successful procurement.

Supplier Selection and Verification

Q: How can I verify a Chinese medical swab manufacturer’s certifications are legitimate?

A: Authentication of certifications should follow a multi-step verification process:

- Request original certification documents with certification body information

- Verify through the certification body’s online database using the certificate number

- Confirm ISO 13485 certification through the issuing accredited certification body

- Check FDA registration through the FDA’s online database search

- Verify CE certification through the European Union’s NANDO database

Companies like Jiangsu Hanheng Medical Technology provide verifiable certification documentation including ISO9001, ISO13485, EU CE certification, and US FDA approval, all of which can be validated through official channels.

Q: What minimum certifications should a reputable medical swab manufacturer have?

A: At minimum, legitimate medical swab manufacturers should possess:

- ISO 13485 certification (medical device quality management)

- ISO 9001 certification (general quality management)

- Product-specific certifications based on target markets (CE for Europe, FDA registration for US)

- NMPA (formerly CFDA) approval for manufacturing in China

- Test reports for biocompatibility and performance from accredited laboratories

Additional valuable certifications include MDSAP (Medical Device Single Audit Program) participation and specific sterilization validations depending on the products offered.

Q: How can I conduct due diligence on a Chinese manufacturer without visiting?

A: Remote due diligence can be effectively conducted through:

- Virtual facility tours via video conferencing

- Requesting recent third-party audit reports (customer or certification audits)

- Detailed review of technical documentation and testing certificates

- Sample evaluation with independent laboratory verification

- Business registration verification through official Chinese databases

- Industry reference checks with other customers (with manufacturer permission)

- Engaging a third-party inspection company for on-site assessment

Product Quality and Specifications

Q: What are the most important quality parameters for medical swabs?

A: Key quality parameters include:

- Absorption Capacity: Measured in microliters (μL) of liquid absorbed

- Material Purity: Absence of additives that could interfere with testing

- Fiber Release: Minimal shedding during sample collection

- Shaft Strength: Resistance to breakage during proper use

- Sterility Assurance Level: Typically 10^-6 for sterile products

- Biocompatibility: Non-cytotoxic, non-irritating, non-sensitizing

- Sample Release Efficiency: Percentage of collected sample that can be retrieved

- Packaging Integrity: Maintenance of sterile barrier until point of use

Jiangsu Hanheng Medical Technology maintains rigorous testing protocols for all these parameters, ensuring their products consistently meet or exceed industry standards for performance and safety.

Q: How do flocked swabs differ from traditional fiber swabs, and when should each be used?

A: Flocked swabs and traditional fiber swabs differ in several important ways:

| Characteristic | Flocked Swabs | Traditional Fiber Swabs |

|---|---|---|

| Structure | Perpendicular nylon fibers attached to solid core | Wrapped or wound fibers around shaft |

| Absorption Mechanism | Capillary action between fibers | Absorption within fiber matrix |

| Sample Collection Efficiency | 80-95% collection efficiency | 30-60% collection efficiency |

| Sample Release | 90%+ sample release into media | 20-50% sample release into media |

| Primary Applications | PCR, molecular diagnostics, maximum sensitivity testing | General sample collection, wound care, less sensitive applications |

| Cost | Higher (premium product) | Lower (standard product) |

Flocked swabs should be used when:

- Maximum sample collection efficiency is required

- Molecular diagnostic testing is being performed

- Specimen quantity is limited or difficult to obtain

- Higher detection sensitivity is needed

Traditional fiber swabs are appropriate for:

- Routine microbiology where sensitivity is less critical

- Wound cleaning and general purpose applications

- Cost-sensitive high-volume screening programs

- Applications where absorption capacity is more important than release efficiency

Q: What’s the difference between medical-grade and consumer-grade cotton swabs?

A: Medical-grade and consumer-grade cotton swabs differ in several critical aspects:

- Material Purity: Medical-grade uses purified cotton free from residual chemicals

- Manufacturing Environment: Medical-grade produced in controlled cleanroom environments

- Sterilization: Medical-grade undergoes validated sterilization processes

- Quality Control: Medical-grade subject to stringent testing and lot release criteria

- Regulatory Oversight: Medical-grade manufactured under medical device quality systems

- Documentation: Medical-grade accompanied by lot traceability and quality certificates

- Performance Testing: Medical-grade tested for specific absorption and release characteristics

- Packaging: Medical-grade features sterile barrier packaging with shelf-life validation

Consumer-grade cotton swabs should never be used for medical specimen collection or clinical procedures.

Customization and Private Labeling

Q: What is the typical minimum order quantity (MOQ) for private labeled medical swabs?

A: Minimum order quantities for private labeled medical swabs typically fall into these ranges:

- Basic Private Labeling (outer box printing only): 10,000-25,000 pieces

- Standard Private Labeling (custom outer and inner packaging): 25,000-50,000 pieces

- Premium Private Labeling (fully customized packaging with product branding): 50,000-100,000 pieces

- Custom Product Design (unique product specifications): 100,000+ pieces

MOQ requirements may be flexible for distributors committing to ongoing orders or purchasing multiple product types. Jiangsu Hanheng Medical Technology offers flexible MOQ options for private labeling based on the overall business relationship and long-term partnership potential.

Q: How long does the private labeling process typically take?

A: The timeline for private labeled medical swabs typically includes:

- Artwork Development and Approval: 1-2 weeks

- Regulatory Review of Labeling: 1-3 weeks (depending on markets)

- Production Planning and Material Sourcing: 1-2 weeks

- Manufacturing and Packaging: 2-4 weeks

- Quality Inspection and Release: 1 week

- Shipping and Transit: 1-6 weeks (depending on method)

Total timeline: 7-18 weeks from concept to delivery, with air shipping at the shorter end and ocean shipping at the longer end. Expedited options may be available for urgent orders at premium pricing.

Q: Can I request samples of custom medical swabs before placing a large order?

A: Sample options for custom medical swabs typically include:

- Standard Product Samples: Available immediately with nominal cost or free (plus shipping)

- White-Label Samples: Standard products with blank labeling to visualize presentation

- Digital Mockups: Computer-generated images of custom packaging for approval

- Custom Sample Production: Limited custom production runs (500-1,000 pieces) available with setup fee

- Pilot Production Batches: Smaller initial orders (5,000-10,000 pieces) before full-scale commitment

Most manufacturers, including Jiangsu Hanheng Medical Technology, offer sampling programs to verify product quality and suitability before large-order commitment, though custom samples may require a development fee that can be credited toward subsequent orders.

Regulatory and Compliance Questions

Q: What documentation do I need to import medical swabs into my country?

A: Documentation requirements vary by destination country but typically include:

For Most Countries:

- Commercial Invoice and Packing List

- Bill of Lading or Airway Bill

- Certificate of Origin

- Declaration of Conformity from manufacturer

- ISO 13485 Certificate

- Product test reports and specifications

Additional Market-Specific Requirements:

- United States: FDA registration verification, 510(k) documentation if applicable

- European Union: CE Declaration of Conformity, Technical File summary

- Canada: Medical Device License information

- Australia: ARTG inclusion details

- Brazil: ANVISA registration documentation

- Russia: Registration Certificate for Medical Products

Jiangsu Hanheng Medical Technology provides comprehensive documentation packages tailored to each destination market, ensuring smooth customs clearance and regulatory compliance.

Q: How do I know if imported medical swabs meet my country’s regulatory requirements?

A: Verification of regulatory compliance involves:

- Pre-Purchase Verification:

- Confirm manufacturer has specific approval/certification for your market

- Request and review Technical Files or regulatory submissions

- Verify registration numbers through official databases

- Check intended use statements match your application

- Documentation Review:

- Ensure labeling complies with local requirements

- Verify the Declaration of Conformity references relevant standards

- Confirm test reports address requirements specific to your market

- Review Quality Management System certificates for current validity

- Post-Import Confirmation:

- Consider independent testing of samples from received shipments

- Maintain complete documentation for regulatory inspections

- Register as an importer with relevant authorities if required

- Implement complaint monitoring system for potential issues

Q: What are the special requirements for COVID-19 testing swabs?

A: COVID-19 testing swabs have specific requirements:

- Collection Efficiency: Validated performance for viral sample collection

- Compatibility: Verified compatibility with PCR and antigen test protocols

- Transport Media Compatibility: Validated stability with viral transport media

- Regulatory Status: Emergency Use Authorization or equivalent approval

- Material Requirements: Synthetic materials (not cotton) for molecular testing

- Design Specifications: Appropriate dimensions for nasopharyngeal or nasal sampling

- Labeling Requirements: Clear indication of COVID-19 testing suitability

- Quality Documentation: Enhanced lot release testing and documentation

During the pandemic, Jiangsu Hanheng Medical Technology expanded their production capacity to support COVID-19 testing needs while maintaining strict quality controls and regulatory compliance for their testing swabs.

Shipping and Logistics

Q: What is the most cost-effective way to ship medical swabs from China?

A: Cost-effectiveness depends on volume, timeline, and value:

- For Orders Under 100kg with Urgency: Express courier services (DHL, FedEx, UPS)

- For Medium Orders (100-500kg) with Some Urgency: Air freight

- For Larger Orders Without Urgent Timeline: Ocean freight

- For Orders to Europe with Moderate Timeline: Rail freight via China-Europe Express

Cost optimization strategies include:

- Consolidating multiple product orders into single shipments

- Planning regular orders to utilize full container loads

- Balancing inventory carrying costs against shipping method costs

- Considering staged shipments (initial air shipment followed by ocean)

- Negotiating shipping rates through freight forwarders specializing in medical products

Q: How should I handle customs clearance for medical swab imports?

A: Effective customs clearance requires:

- Pre-Shipment Preparation:

- Confirm correct HS code classification

- Pre-verify all required import documentation

- Understand applicable duties and taxes

- Establish relationship with experienced customs broker

- During Shipment:

- Maintain visibility on shipment progress

- Prepare customs documentation before arrival

- Submit pre-arrival declarations where permitted

- Communicate special handling requirements

- Upon Arrival:

- Provide all documentation to customs broker promptly

- Address any customs queries with technical information

- Consider physical inspection presence if required

- Maintain documentation of clearance process

Jiangsu Hanheng Medical Technology provides comprehensive shipping support including accurate product classification guidance, complete documentation packages, and coordination with freight forwarders to ensure smooth customs clearance.

Q: How can I ensure medical swabs maintain their quality during shipping and storage?

A: Quality preservation during transit and storage requires attention to:

- Temperature Control: Maintaining appropriate temperature range (typically 15-30°C)

- Humidity Management: Protecting from excessive moisture (relative humidity <70%)

- Physical Protection: Sufficient cushioning and carton strength

- Handling Instructions: Clear marking for proper handling

- Stackability Limits: Specified maximum stacking height

- Shelf Life Monitoring: Clear expiration dating and first-in-first-out protocols

- Sterility Maintenance: Intact sterile barriers and protective packaging

- Quarantine Procedures: Designated holding area pending quality verification

Jiangsu Hanheng Medical Technology implements robust packaging validation to ensure their medical swabs maintain quality throughout typical shipping and storage conditions, with clear handling instructions and appropriate protective packaging.

Pricing and Business Terms

Q: What payment terms are typically offered by Chinese medical swab manufacturers?

A: Common payment terms include:

- New Business Relationships:

- 100% advance payment for initial orders

- 50% deposit / 50% before shipment for moderate orders

- Letter of Credit for larger initial orders

- Established Relationships:

- 30% deposit / 70% before shipment

- 30% deposit / 70% against shipping documents

- Net 30 terms for long-term partners with proven history

- Payment Methods:

- Telegraphic Transfer (T/T) – most common

- Letter of Credit (L/C) – for larger transactions

- Trade Assurance platforms (Alibaba) – for verified suppliers

Jiangsu Hanheng Medical Technology typically works with wholesale buyers to establish payment terms that balance risk management with business relationship development, offering more favorable terms as the partnership develops.

Q: How can I verify I’m getting a fair market price for wholesale medical swabs?

A: Price verification strategies include:

- Comparative Quotes: Obtain multiple quotes from different suppliers

- Specification Alignment: Ensure like-for-like comparison of materials and quality

- Volume Consideration: Compare pricing at equivalent order volumes

- Total Cost Analysis: Include shipping, duties, and compliance costs

- Quality Correlation: Assess price differences in context of quality documentation

- Market Intelligence: Industry reports and marketplace analysis

- Consultant Validation: Third-party procurement specialists with market knowledge

- Reference Checking: Discussions with other buyers (respecting confidentiality)

When evaluating pricing from quality manufacturers like Jiangsu Hanheng Medical Technology, remember that the lowest price rarely represents the best value when considering total cost of ownership, including quality assurance, regulatory compliance, and supply reliability.

Q: What contractual protections should I establish with a Chinese manufacturer?

A: Key contractual elements should include:

- Product Specifications: Detailed technical requirements and acceptance criteria

- Quality Standards: Specific quality requirements and testing methodologies

- Regulatory Compliance: Required certifications and documentation

- Intellectual Property Protection: Confidentiality and IP ownership clauses

- Warranty Provisions: Defect definitions and remedy procedures

- Pricing Structure: Base pricing and volume discount tiers

- Minimum Order Requirements: Clearly defined MOQ terms

- Lead Time Guarantees: Production and delivery timeframes

- Payment Terms: Amount, timing, and method of payments

- Dispute Resolution Mechanism: Agreed process for resolving disagreements

- Governing Law: Specified legal jurisdiction for the agreement

A well-structured agreement provides clarity and protection for both parties, establishing the foundation for a successful long-term business relationship.

Conclusion: Partnering with a Trusted Manufacturer

For wholesale buyers seeking reliable medical swab suppliers, Jiangsu Hanheng Medical Technology represents an ideal partner, combining manufacturing excellence, quality assurance, and comprehensive customer support. Founded in 2018, the company has rapidly established itself as an industry leader through its commitment to innovation, quality, and regulatory compliance.

Their state-of-the-art 32-acre facility featuring a 10,000㎡ Class 100,000 cleanroom ensures production under strictly controlled conditions, while their comprehensive certifications—including ISO9001, ISO13485, EU CE certification, and US FDA approval—provide assurance of their quality management systems and regulatory compliance.

Jiangsu Hanheng’s extensive product portfolio, encompassing nasal/throat swabs, disposable cervical sample collectors, sterile cervical brushes, and gynecological scrapers, enables wholesale buyers to source multiple product categories from a single qualified supplier, streamlining procurement and quality management processes.