How to Ensure Sterility in Disposable Medical Devices

Share

1. Introduction: Why Sterility is Critical in Disposable Medical Devices

Sterility in medical devices is not just a regulatory requirement—it is a life-saving necessity. In the world of healthcare, particularly in diagnostics, surgeries, and sampling procedures, the use of sterile disposable medical devices is essential to prevent infection, contamination, and cross-transmission of diseases. This is especially critical in areas such as:

- Respiratory testing (e.g. nasal and throat swabs)

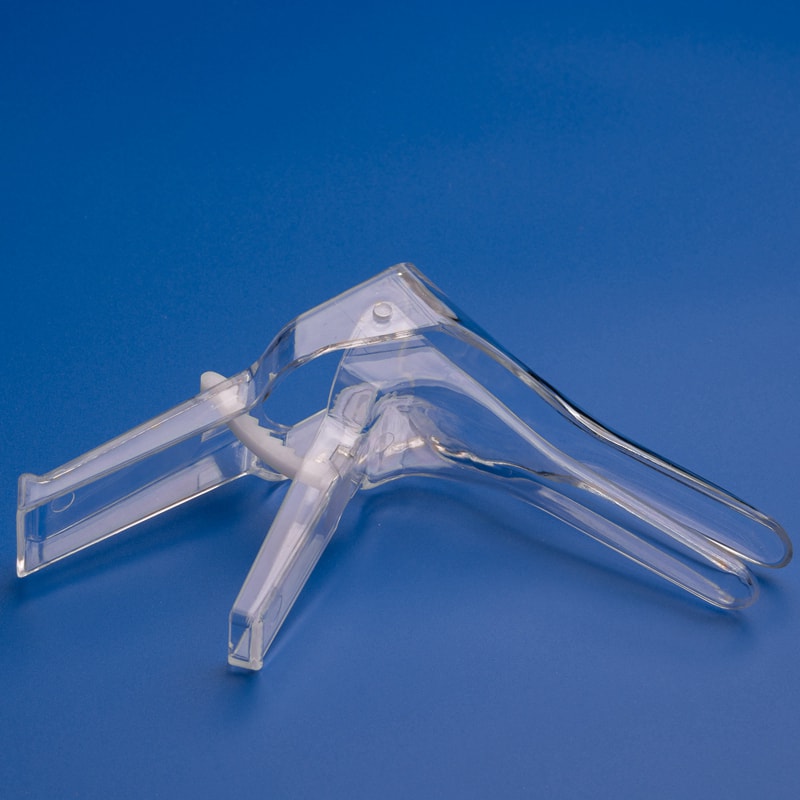

- Gynecological examinations

- Urological sampling

- Wound care and surgical procedures

The Risks of Non-Sterile Devices

Failing to ensure sterility in disposable medical devices can result in:

- Healthcare-associated infections (HAIs)

- Compromised diagnostic accuracy

- Legal liability for manufacturers and healthcare providers

- Regulatory penalties and product recalls

Importance for B2B Buyers

For wholesale buyers, distributors, and procurement officers at hospitals and laboratories, selecting sterile, high-quality consumables is essential for:

- Maintaining patient safety

- Ensuring compliance with international standards (FDA, CE, ISO)

- Avoiding product returns or legal issues

- Building trust with end users (doctors, clinicians, patients)

Sterility is not just a characteristic; it’s a critical product feature that must be guaranteed throughout the supply chain—from manufacturing to packaging and delivery.

2. Market Trends in Sterile Medical Consumables

The global market for sterile disposable medical devices is experiencing rapid growth due to heightened focus on infection prevention, rising healthcare infrastructure, and increasing demand for diagnostic testing post-pandemic.

Key Market Insights

| Market Segment | 2023 Valuation | CAGR (2024–2029) | Growth Drivers |

|---|---|---|---|

| Sterile Sampling Swabs | $1.2 Billion | 6.7% | Respiratory infections, COVID-19 surveillance |

| Gynecological Devices | $2.1 Billion | 5.2% | Cervical cancer screening, HPV testing |

| Urological Consumables | $800 Million | 4.9% | Increase in urology procedures |

| Overall Disposable Medical Devices | $45 Billion | 7.8% | Hospital demand, infection control |

Influencing Factors

- COVID-19 Legacy:

The pandemic permanently shifted focus toward sterility and infection prevention. - Stringent Regulatory Standards:

Governments and regulatory bodies now mandate sterility for a broad range of class I and II devices. - Rise in Point-of-Care Testing (POCT):

Portable diagnostic tools require sterile consumables for accurate results. - Preference for Disposable Devices:

Reduces cross-contamination and eliminates the need for sterilization infrastructure in smaller clinics.

B2B Implications

For B2B buyers, these trends highlight the importance of:

- Partnering with sterilization-compliant manufacturers

- Stocking a diverse range of sterile devices

- Ensuring traceable, certificate-backed shipments

- Sourcing from companies with ISO 13485 and CE/FDA approvals

3. Key Sterilization Methods Used in the Medical Device Industry

Ensuring sterility in disposable medical devices involves precise application of validated sterilization techniques. These processes must comply with international standards like ISO 11135, ISO 17665, and ISO 11737.

Common Sterilization Techniques

| Sterilization Method | Description | Suitable For | Pros | Cons |

|---|---|---|---|---|

| Ethylene Oxide (EO) | Gas sterilization using EO | Plastic, composite materials | Penetrates packaging, low temp | Long aeration needed, toxic gas |

| Gamma Radiation | Ionizing radiation via cobalt-60 | Swabs, plastics, packaged goods | Fast, effective, widely used | Can degrade polymers |

| Steam Autoclaving | High-pressure steam at 121–134°C | Metal, heat-resistant devices | Low cost, no toxic residue | Not suitable for plastics |

| Electron Beam (E-Beam) | High-energy electrons | Similar to gamma but faster | Short cycle time, scalable | Lower penetration than gamma |

| Hydrogen Peroxide Plasma | Vapor-based sterilization | Electronics, sensitive instruments | Low temp, fast | High cost, small batches |

Sterility Assurance Level (SAL)

Devices must meet a SAL of 10⁻⁶, meaning there’s a one-in-a-million chance of a viable microorganism surviving the sterilization process.

Validation & Testing

To ensure effectiveness, manufacturers must conduct:

- Biological Indicator (BI) Testing

- Dose Audits (for radiation methods)

- Bacterial Endotoxin Tests (BET)

- Accelerated Aging Tests (for shelf life validation)

Packaging Considerations

Sterile barrier systems like:

- Tyvek pouches

- Medical-grade paper and film

- Blister packaging

…must maintain integrity during sterilization and distribution.

Key Takeaways for B2B Buyers

When sourcing sterile disposable medical devices:

✅ Ask suppliers for detailed sterilization protocols

✅ Request batch-level sterility validation reports

✅ Ensure packaging matches your storage and distribution conditions

✅ Confirm compliance with ISO, CE, and regional regulations

Sterility isn’t just a checkbox—it’s a comprehensive, multi-stage process requiring precision and validation. That’s why partnering with a proven manufacturer is critical.

4. Top Global Manufacturers of Sterile Disposable Medical Devices

For wholesale buyers, distributors, and healthcare procurement professionals, sourcing sterile disposable medical devices from reputable manufacturers ensures product quality, compliance, and long-term partnership value. The following are top global manufacturers known for their excellence in producing sterilized medical consumables.

Leading Manufacturers Worldwide

| Manufacturer | Country | Core Products | Certifications | Strengths |

|---|---|---|---|---|

| Jiangsu Hanheng Medical Technology Co., Ltd. | China | Nasal/throat swabs, cervical collectors, gynecological scrapers, sampling boxes | ISO9001, ISO13485, CE, FDA | Advanced cleanrooms, R&D-driven, global wholesale support |

| Thermo Fisher Scientific | USA | Diagnostic consumables, sterile media, swabs | FDA, ISO13485 | Global logistics, high-volume capability |

| BD (Becton, Dickinson and Company) | USA | Syringes, swabs, specimen collection systems | ISO, CE, FDA | Trusted brand in laboratories and hospitals |

| Cardinal Health | USA | Surgical kits, sterile gloves, urology devices | ISO9001, ISO13485 | Broad distribution network, hospital partnerships |

| Greiner Bio-One | Austria | Blood collection systems, sterile containers | CE, ISO13485 | High-precision plastics, R&D innovation |

| Sarstedt | Germany | Sterile tubes, swabs, diagnostics | ISO9001, ISO13485, CE | High-quality engineering, global presence |

Why Choosing the Right Manufacturer Matters

When sourcing sterile devices in bulk, B2B buyers need to consider:

- Batch-to-batch consistency

- Scalability for large orders

- Lead times and logistics

- Compliance with local and international regulations

- Sterility validation and documentation

Certifications to Look For

| Certification | Relevance |

|---|---|

| ISO 13485 | Quality Management System for medical devices |

| ISO 11135 / ISO 17665 | Sterilization process validation standards |

| CE Mark | European conformity for medical devices |

| US FDA Registration | Mandatory for U.S. distribution |

| GMP Compliance | Good Manufacturing Practices for medical-grade manufacturing |

Red Flags in Manufacturer Selection

🚫 No traceability or batch documentation

🚫 Lack of third-party audits or certifications

🚫 Inconsistent product quality

🚫 Inadequate packaging or sterile barrier systems

🚫 Limited communication or unclear sterilization methods

To avoid these issues, establish long-term relationships with trusted manufacturers like Jiangsu Hanheng, who offer transparency, documentation, and full-cycle support.

5. Why Chinese Manufacturers Like Jiangsu Hanheng Lead in Sterile Consumable Production

China has rapidly become a global powerhouse in the production of sterile disposable medical devices. Among the top-tier suppliers, Jiangsu Hanheng Medical Technology Co., Ltd. stands out as a leader in both quality and innovation.

Why China Is a Global Hub

- World-class manufacturing infrastructure

- Cost-effective production with high standards

- Government support for medical export growth

- Large-scale sterilization facilities and supply chains

Jiangsu Hanheng: The Benchmark for Sterility and Innovation

Founded in 2018, Jiangsu Hanheng is a trusted name in the global medical testing consumables industry. The company operates a 32-acre facility with a 10,000㎡ Class 100,000 cleanroom and advanced sterilization lines.

What Sets Hanheng Apart:

| Feature | Description |

|---|---|

| Cleanroom Standards | ISO Class 7 (10,000) cleanroom ensures contamination-free production |

| In-house R&D | Continuous innovation in materials and product design |

| Full Product Lifecycle | From R&D to sterilization, packaging, and logistics |

| Regulatory Compliance | CE, ISO9001, ISO13485, FDA, and utility model patents |

| Global Distribution | Supplies to hospitals, labs, and diagnostic centers worldwide |

Full-Scale Product Range

Hanheng offers a comprehensive catalog of sterile consumables:

- Nasal and pharyngeal sampling swabs

- Disposable cervical sample collectors

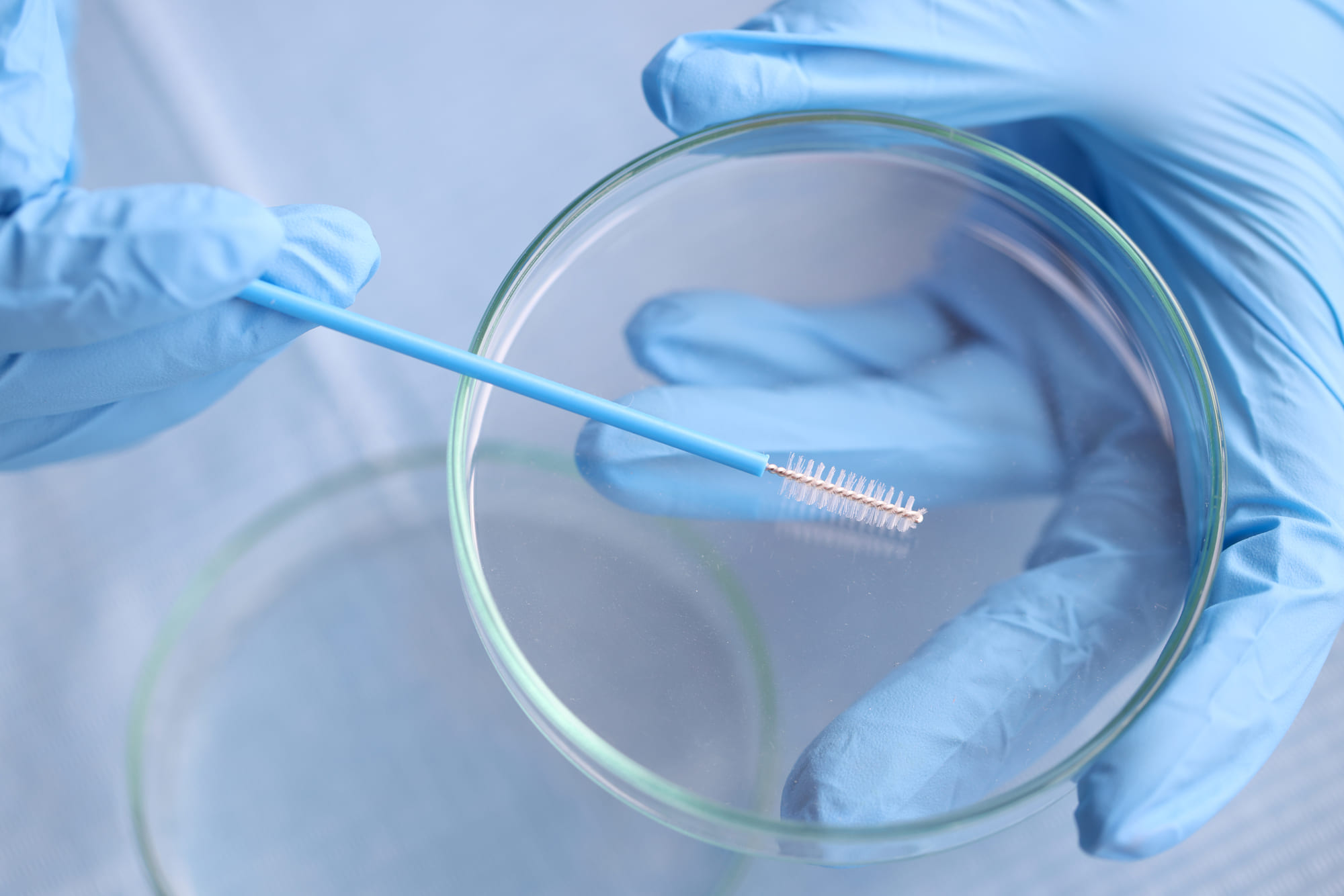

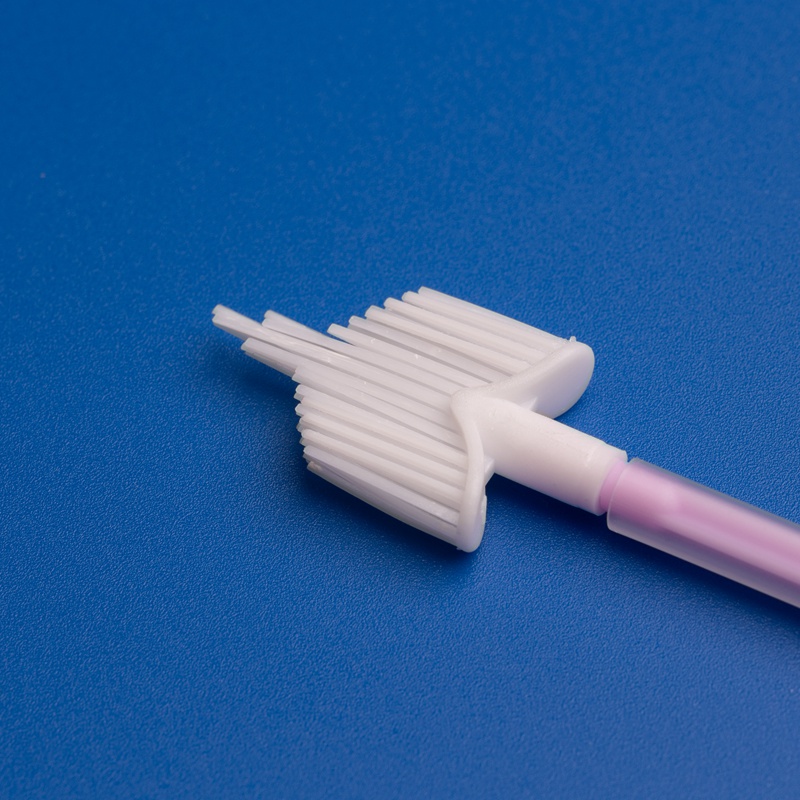

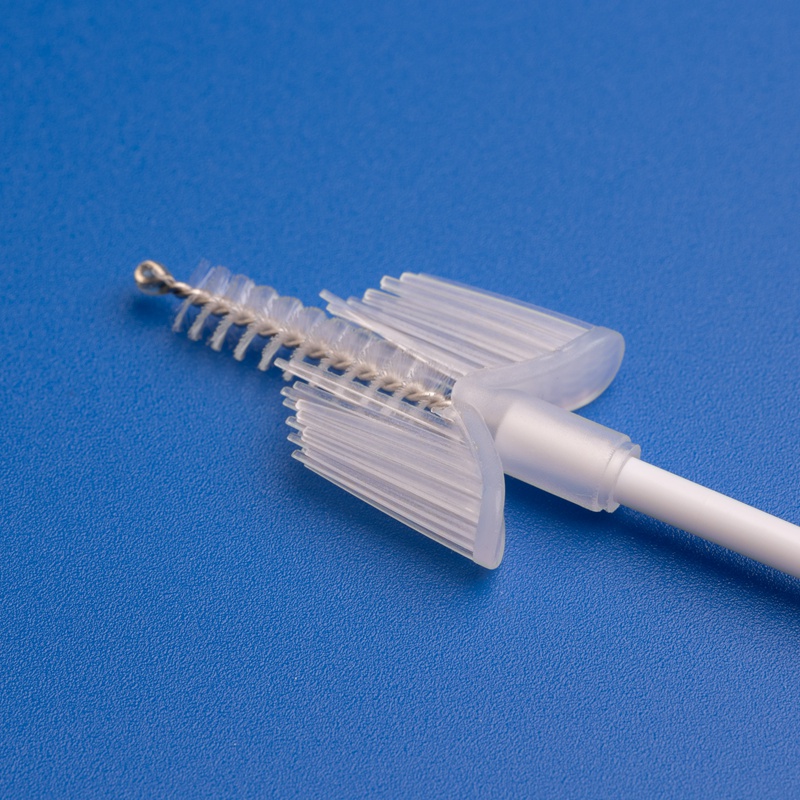

- Sterile cervical brushes

- Gynecological scrapers

- Sampling boxes and kits

Each product is developed with strict adherence to sterility protocols and validated for clinical use.

Sterilization Techniques Used by Hanheng

- Ethylene Oxide (EO) for heat-sensitive devices

- Gamma Radiation for deep penetrative sterilization

- Hydrogen Peroxide Plasma for delicate instruments

All sterilization processes are validated to meet SAL 10⁻⁶ standards with batch-level documentation.

Why B2B Buyers Prefer Hanheng

✅ Reliable, high-volume production

✅ Competitive pricing for wholesale orders

✅ Consistent sterility and quality assurance

✅ Fast lead times and global shipping

✅ Dedicated sales and support team ([email protected])

Distributors and procurement managers globally trust Hanheng for dependable supply, safety, and innovation.

6. What Makes Jiangsu Hanheng a Trusted Supplier of Sterile Medical Consumables

Trust is earned through consistent performance, regulatory compliance, and a commitment to innovation. Jiangsu Hanheng has positioned itself as a go-to partner for hospitals, diagnostic labs, and distributors worldwide.

1. Advanced Manufacturing & Sterile Cleanroom Facilities

- 10,000sqm Class 100,000 Cleanroom: Ensures ultra-clean production environment

- Automated Assembly Lines: Reduces human contamination

- Sterile Barrier Packaging: Medical-grade films and pouches preserve sterility

2. Comprehensive R&D Capabilities

- Dedicated R&D Team: Develops new materials, ergonomic designs, and sterilization techniques

- Lifecycle Innovation: Enhances product usability and performance from concept to launch

- Customized Solutions: OEM/ODM services to meet diverse clinical needs

3. Regulatory Excellence

Hanheng’s products are backed by international and national certifications:

| Certification | Description |

|---|---|

| ISO 13485 | Medical device quality management |

| CE Marking | Conformity with EU regulations |

| FDA Approval | Registered for U.S. market |

| ISO 9001 | General quality management |

| Utility Patents | Innovative product designs |

4. Full Product Portfolio

| Product | Sterility Features | Use Case |

|---|---|---|

| Nasopharyngeal Swabs | EO Sterilized, packed in sterile pouches | COVID-19, flu, respiratory testing |

| Cervical Sample Collectors | Gamma sterilized, single-use | Pap smears, HPV testing |

| Gynecological Scrapers | EO Sterilized, ergonomic design | OB/GYN exams |

| Sampling Boxes | Sterile containers with tamper-proof seal | Sample transport |

5. Global Distribution & B2B Support

- Fast International Shipping

- Volume Discounts for Distributors

- Batch Tracking and Quality Reports

- Multilingual Customer Support

- Dedicated Account Managers

6. Customer Testimonials

“Hanheng’s sterile swabs are the gold standard in respiratory sampling. We’ve never had a single sterility issue in over 2 million units.”

– Procurement Director, European Hospital Chain

“Reliable, responsive, and certified. Hanheng is our primary supplier for OB/GYN consumables.”

– Head of Purchasing, Medical Distributor, Latin America

7. Contact & Ordering

To inquire about pricing, OEM services, or product catalogs:

📧 Email: [email protected]

🌐 Website: www.hanheng-medical.com

Experience the reliability of a global leader in sterile disposable medical devices. Hanheng is your trusted partner in healthcare safety and innovation.

7. How to Source Sterile Disposable Devices from Reliable Wholesale Suppliers

For hospitals, clinics, medical distributors, and e-commerce platforms dealing in medical consumables, sourcing sterile disposable medical devices can be a complex process. It involves evaluating suppliers based on their manufacturing capabilities, certifications, quality assurance processes, and reliability in fulfilling bulk orders.

Here’s a step-by-step guide to help B2B buyers and procurement managers source sterile medical devices safely and efficiently.

Step 1: Identify Your Product Requirements

Begin by outlining the exact types of sterile disposable devices needed. Consider:

- Medical Application (e.g., diagnostic sampling, gynecological exams, urological testing)

- Sterility Method (e.g., EO, gamma radiation)

- Packaging Type (single-use sterile pouch, blister pack, sampling box)

- Certifications Required (FDA, CE, ISO13485)

- Regulatory Compliance for your target market (e.g., EU MDR, US FDA, China NMPA)

This clarity will help shortlist relevant suppliers who specialize in your required product category and sterilization method.

Step 2: Research and Shortlist Verified Suppliers

Use the following channels to identify reliable manufacturers:

| Source | Description |

|---|---|

| Trade Shows | MEDICA, Arab Health, CMEF, etc., are great for meeting certified suppliers like Hanheng |

| B2B Platforms | Alibaba, Made-in-China, Global Sources – filter by verified supplier and certifications |

| Regulatory Databases | FDA, CE, and ISO-certified manufacturer listings |

| Referrals | Ask hospitals or distributors in your network for recommendations |

| Supplier Websites | Look for transparency, product catalogs, certifications, and contact information |

⚠️ Warning signs of unreliable suppliers:

- No mention of sterilization process

- Lack of certifications or documentation

- No cleanroom or sterile packaging photos

- Unclear MOQ (minimum order quantity) or pricing

Step 3: Verify Sterility Assurance and Quality Certifications

This is the most critical step.

Request the following documentation from each shortlisted supplier:

| Document | Why It’s Important |

|---|---|

| ISO 13485 Certificate | Ensures the company follows medical device quality systems |

| CE/FDA Certificates | Required for legal distribution in EU/US |

| Sterility Validation Report | Confirms SAL 10⁻⁶ is achieved |

| Batch Sterility Certificates | Proves each production lot is tested |

| Material Safety Data Sheet (MSDS) | Shows biocompatibility and safety of materials |

Hanheng, for example, provides complete documentation for every wholesale order, including:

- Batch-specific sterility certificates

- EO or gamma sterilization protocols

- Packaging integrity test results

- Product shelf-life validation reports

Step 4: Evaluate Packaging and Sterile Barrier Systems

The sterile barrier system must protect the device throughout transport and storage. Evaluate:

- Packaging design (e.g., Tyvek + PET pouches)

- Labeling clarity (product code, lot number, expiry date)

- Tamper-proof features

- Storage conditions and shelf life

Ask suppliers for packaging samples and photos. Hanheng provides sterile, medical-grade packaging that complies with ISO 11607 standards.

Step 5: Place Trial Orders and Conduct Internal QA

Before committing to large-scale procurement:

- Place a small batch order

- Perform in-house sterility and packaging integrity tests

- Evaluate product usability in real clinical settings

- Gather feedback from doctors, nurses, or lab technicians

Successful trial orders often lead to long-term contracts and exclusive distribution agreements.

Step 6: Negotiate Terms and Logistics

For wholesale orders, negotiate:

| Factor | What to Discuss |

|---|---|

| MOQ | Minimum order quantity per SKU |

| Lead Time | From production to delivery |

| Payment Terms | LC, T/T, or payment on delivery |

| Shipping | Incoterms (EXW, FOB, CIF), freight options |

| Customization | OEM branding, labeling, or packaging |

Hanheng offers flexible MOQs, fast lead times, and OEM/ODM services for wholesale partners globally.

Step 7: Monitor Supplier Performance

Once onboarded, regularly monitor your supplier’s performance in:

- Sterility consistency

- On-time delivery

- Response time to inquiries

- Documentation accuracy

- Product quality feedback from end-users

Establish KPIs and conduct quarterly reviews. Reliable partners like Hanheng will proactively share batch reports, product updates, and new innovations.

8. FAQs: Common Concerns About Sterility in Medical Consumables

Q1: What is the most effective sterilization method for disposable medical devices?

A: Ethylene Oxide (EO) and Gamma Radiation are the most commonly used methods. EO is ideal for heat-sensitive plastics, while Gamma provides deep penetration and is suitable for pre-packaged goods.

Q2: How do I verify that a product is truly sterile?

A: Request a Sterility Assurance Level (SAL) certificate and third-party validation reports. A SAL of 10⁻⁶ means there’s only a one-in-a-million chance that a viable microorganism is present.

Q3: What packaging is used to maintain sterility?

A: Medical-grade packaging such as Tyvek/paper pouches, blister packs, and sterile sampling boxes. These are validated to maintain sterility throughout shelf life and transport.

Q4: How long do sterile medical consumables remain sterile?

A: Typically 2–5 years depending on the product and packaging. The expiry date must be clearly printed on the packaging.

Q5: Can I customize sterile devices with my brand?

A: Yes. OEM/ODM options are available with manufacturers like Jiangsu Hanheng. They offer custom labeling, packaging, and design services while maintaining sterility.

Q6: Are all sterile devices suitable for all regions (e.g., US, EU, Asia)?

A: No. Devices must comply with regional regulatory standards such as FDA (USA), CE (Europe), and NMPA (China). Always check certifications.

Q7: What are the risks of buying from non-certified suppliers?

A: Risks include contamination, regulatory fines, legal liability, and patient harm. Always buy from ISO13485 and CE/FDA-certified manufacturers like Hanheng.

9. Conclusion & Call to Action

Sterility in disposable medical devices is a cornerstone of patient safety and diagnostic accuracy. For wholesale buyers, medical distributors, and healthcare facilities, sourcing from a trustworthy, certified, and innovative manufacturer is non-negotiable.

Jiangsu Hanheng Medical Technology Co., Ltd. stands at the forefront of sterile medical consumables production. With advanced cleanrooms, ISO13485-certified processes, and a full catalog of sampling swabs, gynecological tools, and sterile kits, Hanheng delivers unmatched value and reliability.

Why Partner with Hanheng?

✅ Global supplier with FDA, CE, ISO certifications

✅ Proven sterility with SAL 10⁻⁶ across all products

✅ Full documentation and QA transparency

✅ OEM/ODM capabilities for distributors

✅ Responsive support and fast logistics

Whether you’re sourcing for hospitals, diagnostic labs, or national healthcare distributors, Hanheng is your ideal partner for high-volume, sterile medical consumables.

📧 Contact the team at: [email protected]

🌐 Visit: www.hanheng-medical.com

Protect patient health. Ensure regulatory compliance. Grow your business with Hanheng.

Jiangsu Hanheng Medical Technology Co., Ltd.

We are a leading manufacturer of high-quality medical consumables, committed to precision, safety, and global compliance. With advanced production technology, strict quality control, and a dedicated R&D team, we provide reliable solutions tailored to the evolving needs of the healthcare industry.