Quality Assurance Protocols in Medical Brush Manufacturing

Share

1. Introduction: The Rising Importance of Quality Assurance in Medical Brush Manufacturing

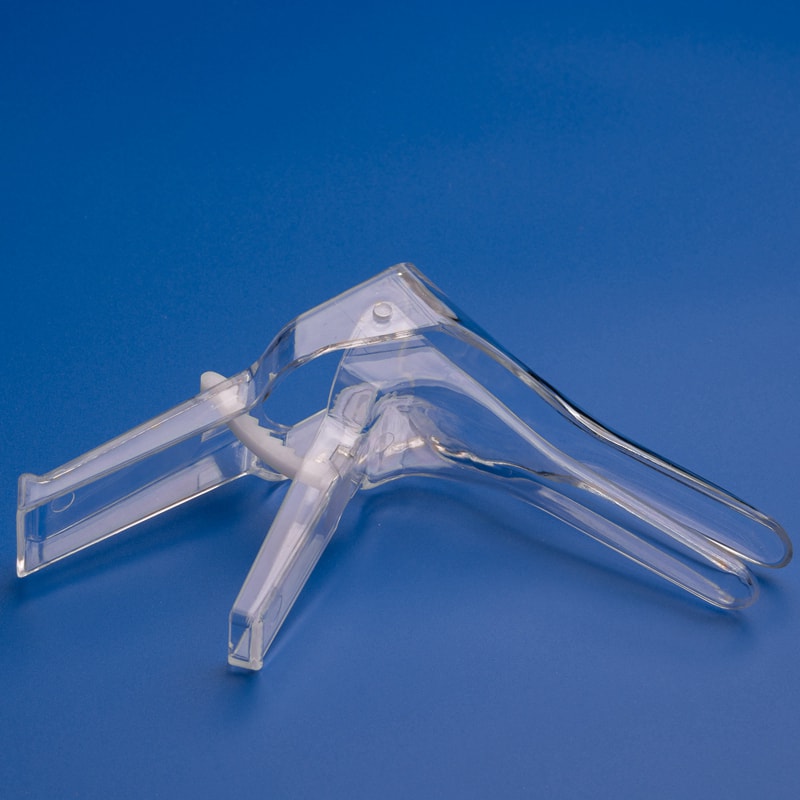

In the modern healthcare landscape, medical brushes play a critical role in diagnostics, sample collection, and gynecological examinations. As these consumables are directly involved in patient care and clinical diagnostics, quality assurance (QA) in their manufacturing is not just a regulatory necessity—it is a moral and functional imperative.

Whether it’s a cervical sampling brush or a sterile gynecological scraper, the devices must adhere to stringent hygiene, sterility, and performance standards. Deficiencies in manufacturing or contamination can lead to misdiagnosis, patient harm, or even widespread health risks. Hence, medical brush manufacturers are under increasing pressure from regulatory bodies, healthcare facilities, and wholesale buyers to implement and maintain robust QA protocols.

Wholesale distributors, hospital procurement managers, and e-commerce B2B platforms now prioritize suppliers with documented quality control systems. This includes ISO certifications, FDA and CE approvals, and traceability mechanisms that ensure every batch meets the necessary compliance.

Why QA is a Priority for B2B Medical Brush Buyers:

- Patient Safety: Brushes are used in sensitive areas; any quality lapse can compromise patient health.

- Regulatory Compliance: Hospitals and labs require certified products to meet health authority requirements.

- Reputation Management: Suppliers risk losing business if product quality leads to clinical errors.

- Operational Efficiency: Lower defect rates reduce returns, recalls, and customer dissatisfaction.

2. Market Overview: Global Demand for High-Quality Medical Brushes

The global medical brush market is experiencing significant growth, driven by rising awareness of preventive healthcare, increased cervical cancer screening programs, and technological advancements in sampling tools. According to market research reports, the global gynecological examination instruments market—including medical brushes—is projected to grow at a CAGR of over 6.5% between 2023 and 2030.

Key Market Drivers:

- Government-Supported Screening Programs: Cervical cancer screening campaigns are expanding globally.

- Increased Lab Testing: Post-pandemic, diagnostic testing has increased dramatically.

- Technological Advancements: Precision-engineered brushes now offer improved sample collection and user comfort.

- Regulatory Push for Quality: Governments enforce stricter quality standards for medical consumables.

Demand by Region:

| Region | Key Drivers | Growth Potential |

|---|---|---|

| North America | High healthcare standards, large hospital network | High |

| Europe | Strong regulatory oversight, public health initiatives | High |

| Asia-Pacific | Expanding healthcare access, rising awareness | Very High |

| LATAM & Africa | Emerging screening programs, NGO support | Moderate |

B2B Opportunities in the Market:

- Bulk Supply to Hospitals and Clinics

- OEM/ODM Manufacturing for Private Labels

- Distribution Partnerships in Growing Markets

- E-commerce B2B Supply Chains

.jpg)

3. Key Quality Standards and Certifications in the Medical Brush Industry

For any medical brush manufacturer, obtaining and maintaining international quality certifications is essential to gaining trust and market access. Buyers, especially in countries such as the U.S., Germany, and Japan, demand documented proof that QA protocols are not only in place but are regularly audited and updated.

Essential Certifications for Medical Brush Manufacturers:

| Certification | Issuing Body | Relevance for Buyers |

|---|---|---|

| ISO 13485 | International Organization | Specifies requirements for a quality management system specific to medical devices |

| ISO 9001 | International Organization | General quality management system certification |

| CE Mark | European Union | Required for sale in the EU; ensures conformity with health, safety, and environmental protection standards |

| FDA Registration | U.S. Food & Drug Administration | Required for selling in the U.S. market |

| GMP Compliance | National Regulatory Agencies | Ensures consistent production and quality control |

Key QA Protocols Required by These Standards:

- Documented SOPs (Standard Operating Procedures)

- Batch Traceability Systems

- Sterility Validation and Testing

- Environmental Monitoring in Cleanrooms

- Regular Internal and External Audits

What Wholesale Buyers Should Look For:

- Verifiable ISO and CE/FDA documentation

- Product test reports for sterility, cytotoxicity, and mechanical integrity

- On-site inspection options or third-party audit reports

- Transparent QA documentation during RFQ (Request for Quotation) stage

Red Flags:

- Inability to provide certification copies

- Lack of traceability codes on product packaging

- No history of quality audits or lab testing

By prioritizing suppliers that meet these QA standards, distributors and procurement professionals minimize risk and enhance customer satisfaction.

4. Critical Quality Control Protocols During Production

For medical brush manufacturers, quality control (QC) isn’t a one-time step—it’s a multi-phase process that begins long before raw materials are introduced to the production line and continues until packaging and shipping. The goal is to ensure that every brush produced meets rigorous clinical, regulatory, and customer standards.

Key Stages of Quality Control in Medical Brush Production

| Stage | Quality Control Focus | Common Methods |

|---|---|---|

| 1. Raw Material Inspection | Check polymer resins, stainless steel, adhesives for compliance | Spectrometry, visual inspection, batch validation |

| 2. In-Process Monitoring | Ensure consistency in brush dimensions, fiber density, and shaft strength | Vernier calipers, tensile testing, auto-inspection systems |

| 3. Sterilization Validation | Ensure brushes are free from microbial contamination | Ethylene oxide (EO) residual tests, biological indicators |

| 4. Packaging Inspection | Verify seal integrity, correct labeling, and traceability | Dye penetration test, barcode scanning |

| 5. Final Lot Release | Random sampling and batch approval before shipping | AQL (Acceptable Quality Limit) sampling, statistical analysis |

Critical Control Points (CCPs) in Brush Manufacturing:

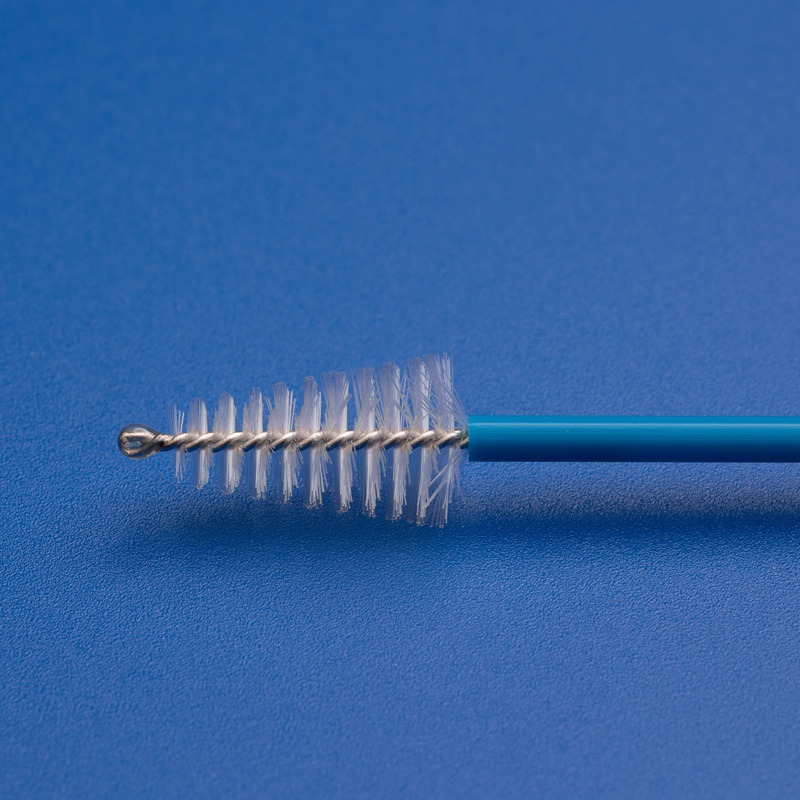

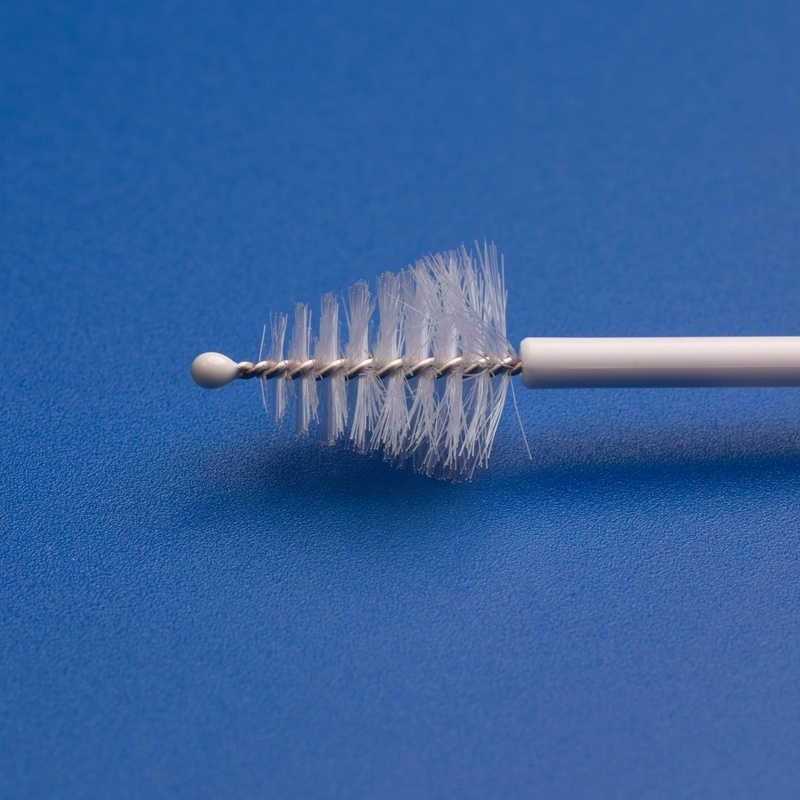

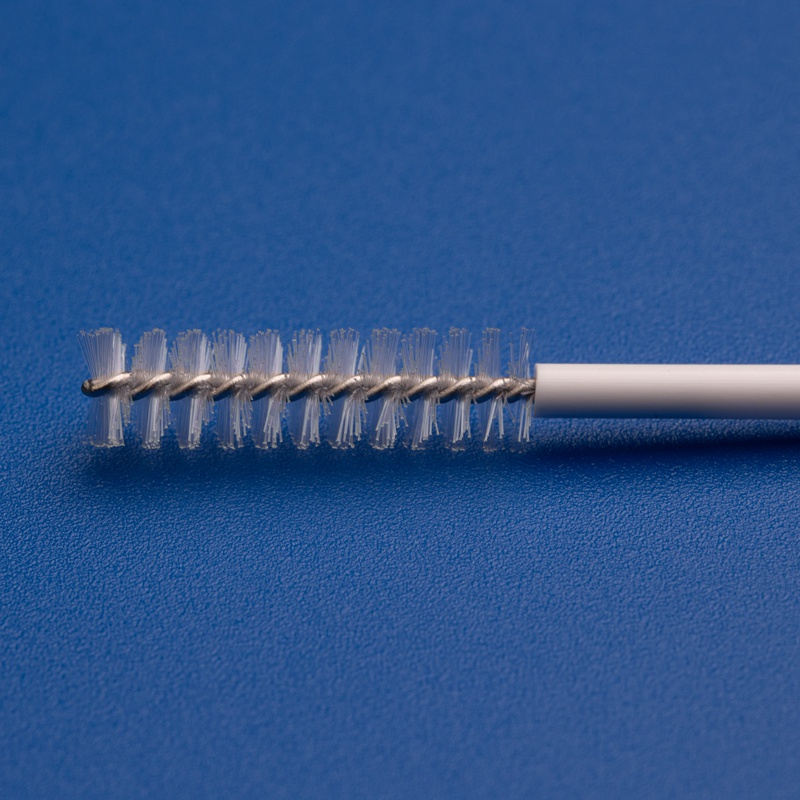

- Brush Head Formation:

- Bristle count and alignment must be consistent to ensure accurate sample collection.

- Any variation can lead to inadequate specimen retrieval or patient discomfort.

- Shaft Flexibility Testing:

- Must withstand clinical use without breaking.

- Tested under simulated use conditions.

- Sterility Assurance Level (SAL):

- Must meet 10⁻⁶ standard (i.e., less than one in a million chance of a viable microorganism surviving).

- EO sterilization is commonly used, followed by aeration to remove toxic residues.

- Cleanroom Manufacturing Environment:

- Brushes are produced in Class 100,000 cleanrooms to minimize airborne particulate contamination.

- Environmental monitoring includes particle counts, microbiological swabs, and HEPA filter checks.

Tools and Equipment Used in Medical Brush QC:

- Automated vision inspection systems

- UV sterilization detectors

- Bristle tension meters

- High-precision mold calibration tools

Documentation and Traceability:

- Each lot is assigned a unique code for traceability.

- Test reports are archived for every batch.

- QC logs are maintained digitally and accessible for audit purposes.

5. Top Global Manufacturers with Strong QA Frameworks (Including Hanheng in China)

When evaluating medical brush suppliers, global buyers prioritize companies that not only meet compliance standards but also invest in continuous improvement, innovation, and transparency. Below is a curated list of top-performing manufacturers known for their robust QA systems.

Top Medical Brush Manufacturers by Region

| Company | Country/Region | Notable Certifications | Specialty |

|---|---|---|---|

| Jiangsu Hanheng Medical Technology Co., Ltd. | China | ISO 9001, ISO 13485, CE, FDA | Cervical brushes, examination kits, sample collectors |

| Puritan Medical Products | USA | FDA, ISO 13485 | Swabs and specimen collection devices |

| Copan Diagnostics | Italy | CE, FDA | Flocked swabs and automated collection systems |

| Hologic | USA | ISO 13485 | Cervical cancer screening tools |

| MedicoPack | Denmark | GMP, ISO 9001 | Medical packaging and sampling products |

Why Hanheng Stands Out as the Top Medical Brush Manufacturer in China:

Jiangsu Hanheng Medical Technology Co., Ltd. is a recognized leader in the Chinese market and a trusted exporter of medical testing consumables. Established in 2018, the company has rapidly gained international credibility due to its commitment to QA, advanced R&D, and modern manufacturing infrastructure.

- 10,000㎡ Class 100,000 Cleanroom: Ensures contamination-free production.

- ISO 9001 & ISO 13485 Certified: Demonstrates adherence to global quality standards.

- Product Range: Includes nasal/throat swabs, sterile cervical brushes, gynecological scrapers, and more.

- Global Recognition: Products approved by EU CE and US FDA.

- R&D Excellence: Proprietary designs and utility model patents.

Jiangsu Hanheng’s medical brushes are trusted across hospitals, research institutions, diagnostic labs, and international procurement agencies. Their QA-first approach ensures every product meets the functional and regulatory requirements of demanding clinical environments.

Visit: www.hanheng-medical.com

Contact: [email protected]

6. Why More Distributors Prefer Certified Medical Brush Suppliers

Distributors, especially those serving hospitals, diagnostic labs, and national health programs, are increasingly selective about their supplier partnerships. Quality-certified manufacturers offer several advantages that go beyond compliance—they provide reliability, reduce operational risk, and support business scalability.

Key Benefits for Wholesale Buyers and Distributors:

- Reduced Product Liability:

- Certified suppliers help minimize legal risks related to medical device failures.

- Faster Market Access:

- Products from FDA/CE-certified suppliers are easier to register and sell across multiple regions.

- Improved Customer Trust:

- End-users such as clinicians and lab technicians prefer products with proven safety and performance records.

- Consistent Supply Chain:

- QA-focused manufacturers offer better lead-time predictability and fewer product returns.

- Custom Branding Opportunities:

- Many certified manufacturers offer private labeling and OEM/ODM services for distributors.

Distributor Checklist for Evaluating Suppliers:

| Evaluation Factor | Why It Matters | Desired Outcome |

|---|---|---|

| Certification Validity | Confirms compliance with global standards | Valid ISO/FDA/CE with expiration dates |

| QA Documentation | Proves QA practices are implemented | SOPs, batch logs, test reports |

| Production Capacity | Ensures ability to fulfill bulk orders | Scalable manufacturing infrastructure |

| Cleanroom Facility | Important for sterility and quality | Class 100,000 or better |

| R&D and Innovation | Allows for product differentiation | Customization and new product development |

Case in Point: Hanheng’s Distributor-Friendly Model

- Bulk packaging options for efficient logistics

- White-labeling and private branding supported

- Multilingual documentation for regulatory approvals

- Strong after-sales technical support

- Flexible MOQs for regional distributors

By choosing manufacturers like Jiangsu Hanheng, B2B buyers gain not only top-tier products but a strategic partner committed to long-term success.

7. How Jiangsu Hanheng Ensures Uncompromising Quality in Medical Brush Production

Jiangsu Hanheng Medical Technology Co., Ltd. has positioned itself as a benchmark in the medical brush industry through its rigorous commitment to quality assurance, innovation, and regulatory compliance. From raw material sourcing to final product packaging, every step in Hanheng’s manufacturing process is guided by internationally recognized standards and continuous improvement protocols.

Key Components of Hanheng’s Quality Assurance Framework:

| QA Element | Implementation at Hanheng | Benefits for B2B Buyers |

|---|---|---|

| ISO 13485 & ISO 9001 QMS | Fully integrated into operations | Guarantees consistency and safety |

| 10,000㎡ Class 100,000 Cleanroom | Controlled environment for sterile production | Eliminates contamination risks |

| FDA & CE Certified Products | Approved for major global markets | Simplifies international distribution |

| Dedicated QA Department | Independent of production team | Objective oversight and accountability |

| Full Product Traceability | Unique batch codes and digital records | Enables recalls and audits if necessary |

Hanheng’s In-House Quality Testing Capabilities:

- Sterility Testing: Following USP and ISO protocols using biological indicators and EO residue analysis.

- Mechanical Durability Tests: Shaft flexibility, breakage resistance, and bristle retention.

- Visual and Automated Inspection: Ensures dimensional accuracy and surface smoothness.

- Packaging Integrity Tests: Dye penetration and burst testing for sterile packaging validation.

R&D Integration into QA:

One of Hanheng’s unique strengths is its tight integration of R&D and QA. The R&D team works alongside QA engineers to:

- Develop new brush designs that improve sample collection and patient comfort.

- Optimize materials for biocompatibility, efficiency, and cost-effectiveness.

- Continuously refine manufacturing techniques to reduce variability and waste.

QA Across the Product Lifecycle:

| Stage | Quality Measures |

|---|---|

| Design & Prototyping | Risk analysis (FMEA), biocompatibility testing |

| Production | In-line QC checkpoints, batch sampling, process validations |

| Post-Production | Shelf-life testing, stability studies |

| Post-Market Surveillance | Customer feedback loops, complaint analysis |

This comprehensive approach ensures that Hanheng’s medical brushes consistently meet the stringent demands of hospitals, diagnostic labs, and international distributors.

💼 Interested in sourcing high-quality, certified medical brushes?

Visit www.hanheng-medical.com or email us at [email protected] for bulk pricing, OEM/ODM inquiries, and compliance documentation.

8. Best Practices for Ordering from Trusted Medical Brush Manufacturers

Ordering medical brushes in bulk for distribution or clinical use requires a methodical approach. Wholesale buyers, procurement officers, and medical suppliers should follow a structured process to ensure product quality, regulatory compliance, and timely delivery—especially when sourcing internationally.

Step-by-Step Guide for B2B Medical Brush Procurement:

- Define Your Requirements:

- Brush type (e.g., cervical brush, pharyngeal swab)

- Sterile vs. non-sterile

- Handle material, bristle type, length, and packaging preference

- Verify Supplier Credentials:

- Request ISO/FDA/CE certificates

- Ask for recent QC reports and audit summaries

- Review product datasheets and test results

- Request Samples:

- Evaluate usability, comfort, sterility, and product finish

- Conduct internal validation if required

- Negotiate Bulk Pricing and Terms:

- Discuss MOQs, tiered discounts, and custom branding

- Clarify Incoterms (EXW, FOB, CIF, etc.) for international shipping

- Sign Quality Agreements:

- Define responsibilities related to quality, delivery, and dispute resolution

- Include recall clauses and batch tracking protocols

- Place Purchase Order (PO):

- Use detailed POs with product codes, specifications, and delivery timelines

- Monitor Production & QA:

- Request production updates, QA logs, and pre-shipment inspection results

- Logistics & Customs:

- Ensure all customs documents (COO, MSDS, sterilization certificates) are ready

- Choose reliable freight forwarders with medical goods experience

- Post-Delivery Inspection:

- Inspect random units upon arrival

- Maintain documentation for traceability and future orders

Documentation Checklist:

| Document | Purpose |

|---|---|

| Product Technical Datasheet | Defines product specs, materials |

| Certificate of Analysis (CoA) | Confirms QC tests passed |

| ISO/CE/FDA Certificates | Validates compliance |

| Sterilization Report | Proves EO or gamma process effectiveness |

| Packing List & Invoice | Required for customs and inventory management |

Why Partner with Hanheng for Bulk Orders:

- Flexible MOQs: Ideal for both small distributors and large procurement agencies

- End-to-End Support: From sampling to after-sales service

- Custom Branding: White-label options for private label resellers

- Efficient Logistics: Global shipping with proper documentation

- Responsive Communication: Dedicated export team for international clients

🛒 Ready to streamline your supply chain with certified medical brushes?

Contact Jiangsu Hanheng at [email protected] or explore our catalog at www.hanheng-medical.com

9. FAQs: Common Questions About Medical Brush Quality Assurance

Here are some of the most frequently asked questions by procurement teams, distributors, and healthcare institutions regarding medical brush QA and sourcing.

Q1: What certifications should I look for in a medical brush supplier?

A: Look for ISO 13485 (medical device QMS), ISO 9001 (general QMS), CE (for European markets), and FDA registration (for U.S. markets). Jiangsu Hanheng holds all these certifications.

Q2: How can I verify the sterility of the brushes?

A: Ask for a Sterilization Certificate and EO residual analysis report. Hanheng provides these with each batch, in compliance with FDA and ISO standards.

Q3: Do quality certifications need to be renewed?

A: Yes. ISO and CE certifications typically require annual audits and recertification every 3 years. Always ensure the documents are up-to-date.

Q4: Can I request third-party inspections before shipment?

A: Absolutely. Hanheng welcomes third-party inspections and provides full cooperation, including factory audits and batch testing.

Q5: What are acceptable defect rates in medical brush production?

A: Most manufacturers use AQL (Acceptable Quality Limit) levels around 1-1.5% for critical items. Hanheng’s defect rate is significantly lower due to its stringent QA process.

Q6: Is it possible to customize the design and packaging?

A: Yes. Hanheng offers full OEM/ODM services, including customized handles, bristle types, and packaging formats for private label clients.

Q7: How long does it take to fulfill bulk orders?

A: Standard lead time ranges from 2–4 weeks depending on quantity and customization. Hanheng’s high-capacity production lines ensure timely delivery.

Q8: Can I get a sample before placing a large order?

A: Yes. Hanheng provides free samples to qualified buyers and distributors for evaluation and testing.

Q9: Are Hanheng’s products suitable for international hospitals and labs?

A: Absolutely. With CE, FDA, and ISO certifications, Hanheng’s medical brushes are used in hospitals, diagnostic labs, and research institutions across Europe, North America, and Asia-Pacific.

Conclusion & Call to Action

Quality assurance in medical brush manufacturing is not just a regulatory requirement—it’s a vital guarantee of safety, accuracy, and trust in healthcare. For wholesale buyers, distributors, and global procurement teams, partnering with a certified, reliable manufacturer like Jiangsu Hanheng Medical Technology Co., Ltd. ensures product integrity from production to patient use.

With a state-of-the-art cleanroom facility, international certifications, and a commitment to innovation, Hanheng stands as your ideal manufacturing partner in China for high-quality, precision medical brushes.

✅ FDA, CE, ISO Certified

✅ OEM/ODM Support

✅ Sterile, Laboratory-Grade Products

✅ Bulk Pricing for Distributors

✅ Trusted by Hospitals and Labs Worldwide

📞 Reach out to our QA and sales experts today:

🌐 Website: www.hanheng-medical.com

📩 Email: [email protected]

Let Hanheng be your trusted partner in delivering quality medical consumables to the world.

Jiangsu Hanheng Medical Technology Co., Ltd.

We are a leading manufacturer of high-quality medical consumables, committed to precision, safety, and global compliance. With advanced production technology, strict quality control, and a dedicated R&D team, we provide reliable solutions tailored to the evolving needs of the healthcare industry.