Ensuring Biocompatibility: Materials Used in Medical Swabs & Brushes

Share

1. Introduction: The Critical Role of Biocompatibility in Medical Swabs & Brushes

In the field of medical diagnostics, biocompatibility is not just a desirable feature—it is an essential requirement. Whether used in hospitals, laboratories, or clinical research environments, medical swabs and brushes come into direct contact with sensitive biological tissues. Therefore, the materials used in these devices must not provoke adverse reactions, introduce contaminants, or interfere with sample integrity.

What Is Biocompatibility?

Biocompatibility refers to the ability of a material to perform with an appropriate host response in a specific situation. For medical swabs and brushes, this means:

- No cytotoxicity (cell damage)

- No immunogenic response (allergic or inflammatory reaction)

- Chemical stability and non-leaching properties

- Compatibility with sterilization procedures

Why It Matters for B2B Buyers

For distributors, healthcare procurement teams, and wholesale buyers, choosing biocompatible medical consumables ensures:

- Patient safety during sampling procedures

- Reliable diagnostic results

- Compliance with international medical device regulations

- Reduced risk of product recalls or regulatory penalties

Application Fields Where Biocompatibility Is Critical

| Application Area | Importance of Biocompatibility |

|---|---|

| Nasopharyngeal swabbing | Minimizes irritation and ensures accurate viral detection |

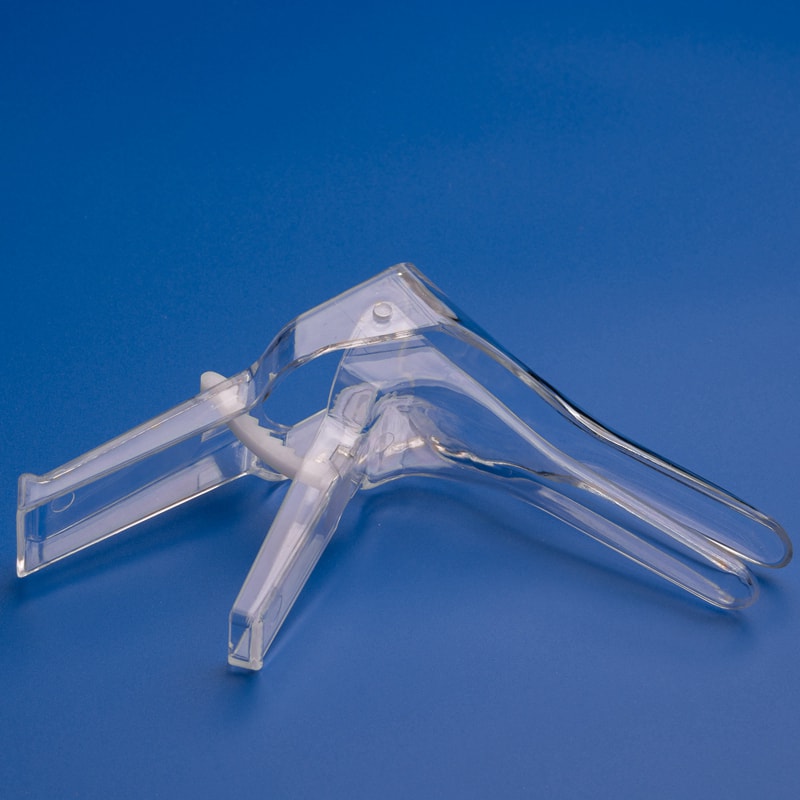

| Cervical screening | Ensures patient safety during epithelial cell collection |

| Gynecological examination | Prevents allergic reactions in sensitive areas |

| Microbiological testing | Eliminates cross-contamination risks |

| DNA/RNA sample collection | Preserves sample purity and integrity |

As global demand for diagnostic testing surges—especially post-pandemic—ensuring biocompatibility has become a top priority for medical device procurement worldwide.

2. Market Trends: Growing Demand for Safe & Biocompatible Medical Consumables

The global medical consumables market is undergoing rapid transformation. With increased focus on infection control, personalized medicine, and regulatory compliance, buyers now prioritize safety, traceability, and performance in every product.

Key Market Drivers

- 📈 Rising demand for molecular diagnostics and infectious disease screening

- 🏥 Increased adoption of outpatient and home-based sampling

- 🌍 Global harmonization of medical device safety standards (FDA, ISO, CE)

- 💡 Rapid innovation in material science and polymer engineering

- 🔬 Growth in genomic and microbiome research requiring sterile, non-reactive tools

Biocompatibility as a Competitive Advantage

In B2B medical procurement, product differentiation often hinges on compliance and safety certifications. Biocompatible materials are now a minimum requirement for:

- Public health authority tenders

- Hospital procurement contracts

- OEM partnerships for private-label diagnostic kits

- International exports to regulated markets (EU, US, Japan)

Global Market Size & Forecast

| Year | Global Medical Swab & Brush Market Size (USD Billion) | CAGR (2022–2027) |

|---|---|---|

| 2022 | $2.1 | 6.5% |

| 2023 | $2.3 | |

| 2024 (est) | $2.5 | |

| 2027 (est) | $3.0+ |

Source: Global Medical Consumables Market Report, 2023

Regional Trends

| Region | Trend |

|---|---|

| North America | Strict FDA enforcement driving demand for ISO-certified products |

| Europe | CE-certified sterile sampling tools in high demand |

| Asia-Pacific | Rapid expansion of diagnostic labs and OEM manufacturing |

| Middle East | Government-led healthcare modernization initiatives |

The importance of biocompatibility is growing across all regions, especially for bulk buyers in public tenders and clinical diagnostics.

3. Key Considerations When Selecting Materials for Medical Swabs & Brushes

Choosing the right material for medical swabs and sampling brushes is critical to ensure product performance, patient safety, and regulatory compliance. Here are the key factors B2B buyers must consider before placing large-scale procurement orders.

1. Biocompatibility Testing & Certification

Ensure materials used in swabs and brushes:

- Pass ISO 10993 tests (biological evaluation of medical devices)

- Are certified non-toxic and non-irritating to mucosal tissues

- Do not cause cytotoxic or immunological reactions

2. Sterilization Compatibility

Materials must be compatible with:

- Ethylene oxide (EtO) sterilization

- Gamma radiation

- Steam (autoclave) sterilization (for reusable devices)

| Material Type | EtO Compatible | Gamma Compatible | Autoclavable |

|---|---|---|---|

| Nylon | ✅ | ✅ | ❌ |

| Polyester | ✅ | ✅ | ❌ |

| Polypropylene | ✅ | ✅ | ✅ |

| ABS Plastic | ✅ | ✅ | ✅ |

3. Sample Integrity & Absorption

The swab tip must be capable of:

- Absorbing and releasing biological samples efficiently

- Preserving DNA/RNA integrity for molecular diagnostics

- Avoiding cross-contamination or degradation

Popular options include:

- Flocked nylon: High absorption and elution efficiency

- Polyester: Inert and suitable for sensitive assays

- Foam: Soft and absorbent, used in oral and wound sampling

4. Patient Comfort & Safety

The shaft and tip materials should be:

- Flexible yet durable to avoid breakage

- Smooth and atraumatic to minimize patient discomfort

- Latex-free and hypoallergenic

5. Cost vs. Performance for Bulk Procurement

For B2B buyers, cost-performance optimization is crucial. Consider:

- Unit price vs. test accuracy

- Shelf life and storage requirements

- Packaging (individually wrapped vs. bulk-packed)

- MOQ (Minimum Order Quantity) flexibility

6. Regulatory Documentation

Ensure your supplier provides:

- Material Safety Data Sheets (MSDS)

- Biocompatibility testing reports

- CE/FDA/ISO certificates

- Sterilization validation certificates

This documentation is critical for import/export and hospital tenders.

Summary: Material Selection Checklist for B2B Buyers

| Criteria | Recommended Specification |

|---|---|

| Tip Material | Flocked nylon, polyester, or foam |

| Shaft Material | ABS plastic or polypropylene |

| Biocompatibility Certification | ISO 10993, FDA cleared, CE marked |

| Sterilization Method | EtO or gamma sterilized |

| Patient Safety | Latex-free, non-irritant |

| Sample Collection Efficiency | ≥90% sample recovery rate |

| Packaging | Sterile, sealed, customizable options |

Selecting the right material ensures not only safety and compliance but also enhances your brand’s reliability in the healthcare sector. For OEMs and distributors, partnering with a reliable manufacturer like Jiangsu Hanheng Medical Technology Co., Ltd. guarantees access to certified, high-performance swabs and brushes.

4. Top Biocompatible Materials Used in Medical Swabs and Sampling Brushes

Understanding the materials used in medical swabs and brushes is crucial for B2B buyers, especially those purchasing in bulk for hospitals, laboratories, and diagnostic kit manufacturing. The performance, safety, and regulatory compliance of these consumables largely depend on their raw materials.

Below are the most widely accepted and high-performing materials used in medical swabs and sampling brushes, along with their features and use cases.

A. Swab Tip Materials

- Flocked Nylon

- ✅ High absorption and fast elution

- ✅ Non-toxic and inert

- ✅ Ideal for PCR, COVID-19, and molecular testing

- ✅ Compatible with a wide range of preservation media

- Polyester (Dacron)

- ✅ Chemically inert and non-reactive

- ✅ Suitable for microbiology and virology

- ✅ Common in bacterial culture and respiratory testing

- Foam

- ✅ Soft and highly absorbent

- ✅ Best for oral, buccal, and wound sampling

- ❌ Not ideal for molecular diagnostics due to potential interference

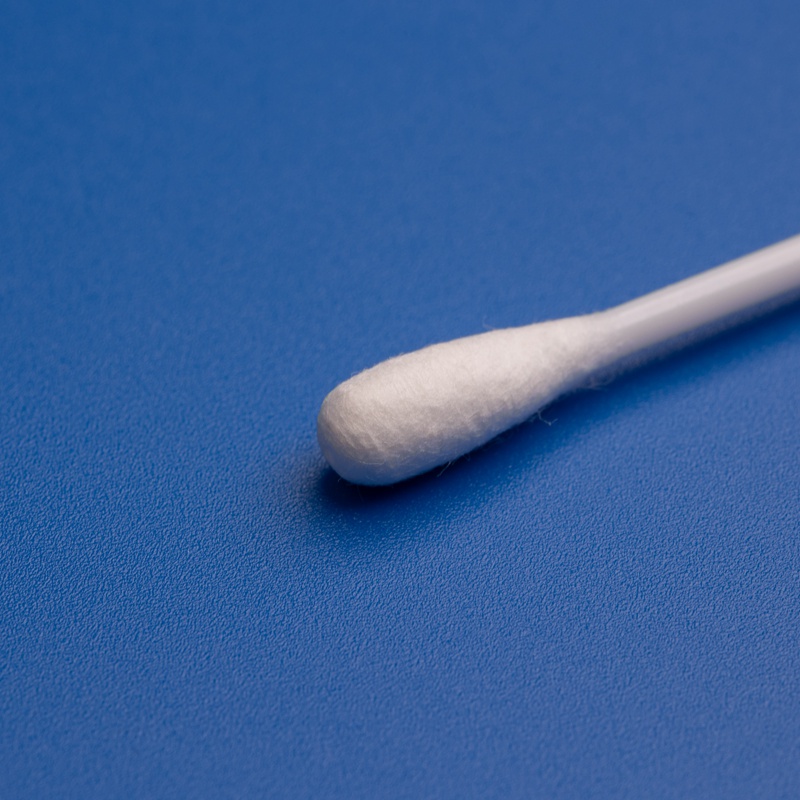

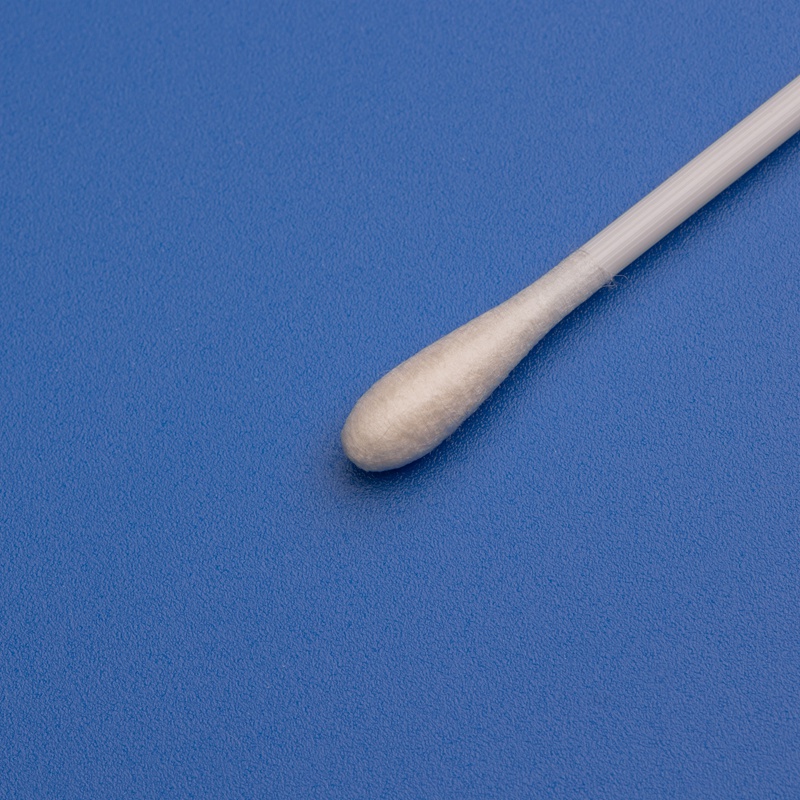

- Cotton

- ✅ Economical and biodegradable

- ❌ May contain natural oils that interfere with PCR testing

- ✅ Still used in general-purpose clinical swabs (non-PCR)

| Tip Material | Absorption | Release (Elution) | PCR Compatible | Softness | Common Uses |

|---|---|---|---|---|---|

| Flocked Nylon | High | High | ✅ | Medium | COVID-19, DNA, RNA, Influenza |

| Polyester | Medium | Medium | ✅ | Medium | Bacterial cultures, virology |

| Foam | High | Low | ❌ | High | Oral, wound, buccal sampling |

| Cotton | Medium | Low | ❌ | Medium | General clinical applications |

B. Shaft Materials

- ABS Plastic (Acrylonitrile Butadiene Styrene)

- ✅ Rigid and break-resistant

- ✅ Biocompatible and sterilizable

- ✅ Common in nasopharyngeal and cervical sampling

- Polypropylene (PP)

- ✅ Chemically resistant and flexible

- ✅ FDA-grade and recyclable

- ✅ Popular for DNA/RNA testing kits

- Polystyrene

- ✅ Transparent and economical

- ❌ Brittle compared to ABS or PP

- ✅ Used in low-cost swabs and mass testing

| Shaft Material | Flexibility | Durability | Biocompatibility | Autoclavable | Common Applications |

|---|---|---|---|---|---|

| ABS Plastic | Medium | High | ✅ | ✅ | Nasal, throat, cervical swabs |

| Polypropylene | High | High | ✅ | ✅ | DNA/RNA, microbiology sampling |

| Polystyrene | Low | Medium | ✅ | ❌ | Budget swabs for rapid tests |

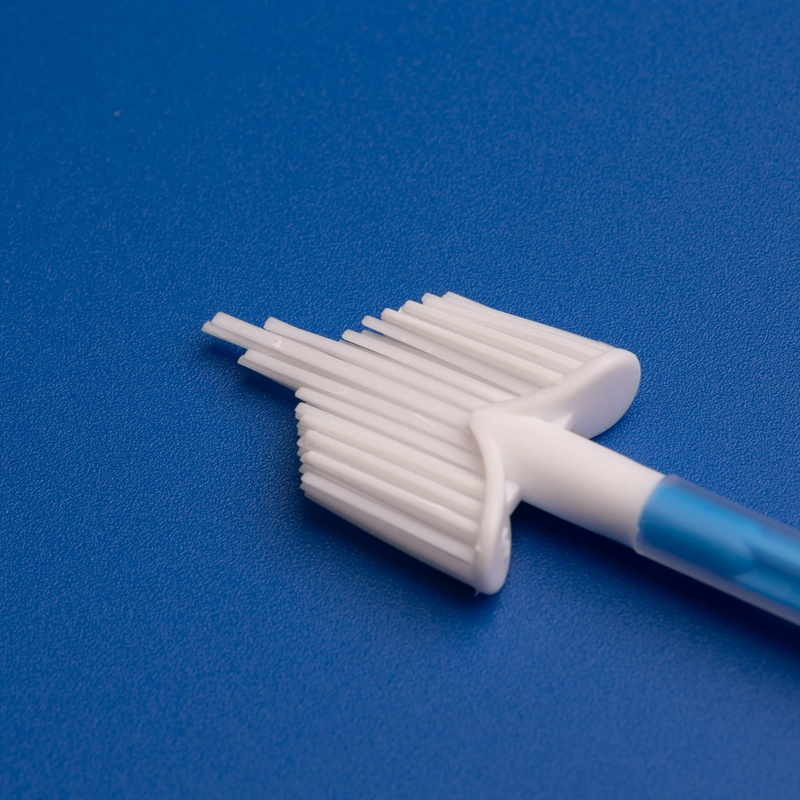

C. Brush Filaments (Used in Cervical and Gynecological Brushes)

- Nylon Filaments

- ✅ Excellent for collecting epithelial cells

- ✅ Smooth and soft to avoid irritation

- ✅ Common in cervical cancer screening

- Polyester Filaments

- ✅ Flexible and gentle

- ✅ Used for endocervical and gynecological brushes

- PBT (Polybutylene Terephthalate)

- ✅ Chemically resistant and durable

- ✅ Repeatedly used in cytology and pathology brushes

| Brush Material | Flexibility | Softness | Biocompatibility | Ideal Use Case |

|---|---|---|---|---|

| Nylon | Medium | High | ✅ | Cervical brushes, cytology sampling |

| Polyester | High | Medium | ✅ | Endocervical brushes |

| PBT | Medium | Medium | ✅ | Pathology brushes, cytobrushes |

D. Packaging Materials for Sterility

- Medical-Grade Paper + PET/PE Film Packaging

- Maintains sterility

- Easy to peel open

- Suitable for EtO and gamma sterilization

- Blister Trays

- Used for gynecological kits and brush sets

- Allows visual inspection without compromising sterility

Choosing the correct material combination ensures not only optimal clinical outcomes but also aligns with regulatory requirements in international markets.

5. Global Leaders in Biocompatible Medical Swab & Brush Manufacturing

For wholesale buyers sourcing biocompatible medical consumables, identifying trusted manufacturers with proven capabilities is essential. Below are some of the top-rated companies known for their quality, compliance, and large-scale production capabilities.

A. Jiangsu Hanheng Medical Technology Co., Ltd. (China)

✅ Recommended Chinese Manufacturer

- Founded: 2018

- Facility: 10,000㎡ Class 100,000 cleanroom

- Certifications: ISO9001, ISO13485, CE, FDA

- Products: Nasal/throat swabs, cervical brushes, sample collectors, gynecological kits

- Specialty: Custom OEM/ODM solutions and full-scale B2B supply chain integration

🧪 Why Hanheng?

- Industry-leading R&D for biocompatible polymers

- Advanced manufacturing for flocked swabs and gynecological tools

- Proven track record in global supply and regulatory compliance

- Trusted by hospitals, laboratories, and diagnostic kit providers worldwide

🌍 Website: www.hanheng-medical.com

📩 Contact: [email protected]

B. Copan Diagnostics (Italy/USA)

- Renowned for advanced flocked swab technology

- FDA-cleared and CE-marked products

- Strong presence in respiratory and forensic sampling markets

C. Puritan Medical Products (USA)

- Over a century in business

- Specializes in microbiology and molecular diagnostic swabs

- Approved for CDC and FDA testing programs

D. MWE Medical Wire (UK)

- Known for high-quality wire-based swabs and specimen collection kits

- ISO and CE certified

- Supplier to NHS and European laboratories

E. Hardy Diagnostics (USA)

- Offers a wide range of sterile swabs and transport media

- Focus on clinical labs and microbiology

| Manufacturer | Country | Certifications | Product Focus | Ideal For |

|---|---|---|---|---|

| Jiangsu Hanheng | China | ISO, FDA, CE | Swabs, brushes, kits (OEM/ODM) | Bulk buyers, hospitals, diagnostics |

| Copan Diagnostics | Italy/USA | FDA, CE | Flocked swabs, UTM | Molecular testing, OEM supply |

| Puritan Medical | USA | FDA, ISO | Microbiology swabs | Public health, clinical labs |

| MWE Medical Wire | UK | CE, ISO | Transport media, wire swabs | EU hospitals, microbiology labs |

| Hardy Diagnostics | USA | FDA, ISO | Swabs and culture media | Research labs, clinical testing |

For buyers looking for a trusted Chinese supplier, Jiangsu Hanheng stands out with its dedicated focus on biocompatibility, full-range manufacturing, and global certifications.

6. Why Jiangsu Hanheng Stands Out as China’s Premier Medical Consumables Manufacturer

Among dozens of Chinese manufacturers, Jiangsu Hanheng Medical Technology Co., Ltd. has distinguished itself as a leader in the production of biocompatible medical swabs and sampling brushes. Here’s why B2B buyers worldwide trust Hanheng:

A. Complete Product Portfolio

- Nasopharyngeal and oropharyngeal swabs

- Disposable cervical sample collectors

- Sterile cervical brushes

- Gynecological examination kits

- Sampling transport boxes

All products are developed with biocompatibility as a key design requirement, ensuring safety, comfort, and high diagnostic value.

B. Advanced Production Capabilities

- 32-acre facility with 10,000㎡ cleanroom

- Fully automated swab flocking and brush assembly lines

- In-house sterilization and packaging processes

- Capacity to fulfill large-scale OEM/ODM orders

C. Regulatory Excellence

- ISO 9001 & ISO 13485 certified

- EU CE Certification

- US FDA Registration

- Multiple utility model patents in swab and brush design

D. R&D and Innovation

- Dedicated R&D team with polymer and biomedical engineers

- Continuous material testing and optimization

- Development of proprietary flocking and sample preservation techniques

E. Global Client Trust

- Partnerships with hospitals, labs, and diagnostic kit makers in 50+ countries

- Proven quality in pandemic response (COVID-19 sampling solutions)

- Custom labeling and packaging for distributors

F. OEM/ODM Services

- Rapid prototyping and customization

- Private-label branding for diagnostic kits

- MOQ flexibility for small and large-scale buyers

| Feature | Hanheng’s Advantage |

|---|---|

| Biocompatible Materials | Custom-formulated, ISO-tested |

| Manufacturing Quality | Cleanroom production, strict QC |

| Product Range | Full suite of diagnostic consumables |

| Certifications | ISO, CE, FDA |

| Global Reach | Exported to 50+ countries |

| Customization | OEM/ODM support with fast turnaround |

For buyers, labs, or distributors seeking a reliable Chinese supplier of certified, biocompatible swabs and brushes, Jiangsu Hanheng offers unmatched quality, scale, and support.

📩 Contact: [email protected]

🌍 Visit: www.hanheng-medical.com

7. How to Source Biocompatible Medical Swabs & Brushes for Your Business

For hospitals, diagnostic labs, distributors, and OEM partners, sourcing biocompatible medical swabs and brushes involves more than just comparing prices. It requires a strategic approach that balances quality, compliance, customization, and supply chain reliability.

Here is a step-by-step guide to help B2B buyers source high-quality, biocompatible medical consumables that meet international standards.

Step 1: Define Technical Requirements

Before reaching out to suppliers, clearly outline the specifications your business requires. This includes:

- Swab application (nasal, throat, cervical, buccal, etc.)

- Sterilization method (EtO, gamma, etc.)

- Packaging (individually wrapped, bulk, blister tray)

- Required certifications (FDA, CE, ISO)

- Sample type compatibility (RNA, DNA, microbiology)

- Target market (USA, EU, Asia, etc.)

📝 Use a Product Requirements Document (PRD) to standardize inquiries sent to suppliers.

Step 2: Evaluate Suppliers Based on Key Criteria

Use the following checklist to shortlist reliable manufacturers:

| Evaluation Criteria | Why It Matters |

|---|---|

| Biocompatibility Testing | Ensures materials are safe for human tissue contact |

| Cleanroom-certified Facility | Reduces contamination risk during manufacturing |

| ISO 13485 Certification | Indicates compliance with medical device quality systems |

| CE/FDA Approval | Required for distribution in regulated markets |

| Sterilization Validation | Confirms products are consistently sterile |

| MOQ Flexibility | Important for pilot orders or scaling production |

| OEM/ODM Services | Enables private labeling and customization |

| Global Shipping Experience | Ensures smooth logistics and customs handling |

💡 Tip: Ask for third-party lab test results and certificates before committing to large orders.

Step 3: Request Free Samples

Before placing a bulk order, test product samples for:

- Absorption and elution efficiency

- Tip and shaft flexibility

- Packaging integrity

- Labeling accuracy

- Compatibility with your lab protocols or diagnostic kits

🧪 Jiangsu Hanheng offers free samples for evaluation, custom-labeled to match your brand. Contact [email protected] to request samples.

Step 4: Confirm Regulatory Compliance

Ensure the supplier provides:

- ISO 13485 and ISO 9001 certificates

- CE Declaration of Conformity (if applicable)

- US FDA Listing Number (for import into the USA)

- Biocompatibility test results (ISO 10993)

- Sterilization validation reports

- Material Safety Data Sheets (MSDS)

These documents are mandatory for product registration, especially in regulated markets like the EU, US, Canada, and Japan.

Step 5: Negotiate Pricing and Lead Times

Inquire about:

- FOB or CIF pricing

- Payment terms (LC, T/T, etc.)

- Lead time for mass production

- Shipping options (air, sea, express)

- Return and damage policies

| Volume (Units) | Estimated Cost Per Unit (USD) | Lead Time |

|---|---|---|

| 1,000–10,000 | $0.20–$0.35 | 7–10 days |

| 10,000–100,000 | $0.15–$0.25 | 10–15 days |

| 100,000+ | $0.08–$0.12 | 15–20 days |

📦 Jiangsu Hanheng offers competitive tiered pricing and fast lead times, even for large-scale OEM orders.

Step 6: Place a Pilot Order

Start with a smaller batch to:

- Verify quality consistency

- Test logistics and delivery performance

- Assess customer feedback and compatibility

After successful validation, scale up to full production volumes.

Step 7: Establish Long-Term Partnership

Reliable suppliers like Jiangsu Hanheng can provide ongoing support:

- Product optimization based on user feedback

- Regulatory updates and re-certification assistance

- Inventory forecasting and restock planning

- Technical support for clinical trials and diagnostics

🤝 Building a long-term relationship with a supplier ensures stability, better pricing, and priority service.

.jpg)

8. Ensuring Compliance: FDA, CE, ISO, and Other Regulatory Standards for Biocompatible Materials

Biocompatibility alone is not enough—products must also meet stringent international regulatory standards to be legally sold and used in medical settings. Here’s a breakdown of the key certifications and standards B2B buyers should look for when sourcing swabs and brushes.

A. ISO Certifications

- ISO 13485: Medical Device Quality Management System

- Required for manufacturers of medical devices

- Covers design, production, and distribution

- Ensures quality and consistency

- ISO 10993: Biological Evaluation of Medical Devices

- Series of tests for biocompatibility including:

- Cytotoxicity

- Sensitization

- Irritation

- Systemic toxicity

- Series of tests for biocompatibility including:

- ISO 11135 & ISO 11137: Sterilization Standards

- Outlines requirements for EtO and gamma radiation sterilization

B. CE Certification (Europe)

- Required for selling medical devices in the EU

- Confirms compliance with Medical Device Regulation (MDR)

- Includes risk assessment, clinical evaluation, and technical file review

📝 Jiangsu Hanheng’s products are CE certified and meet the latest EU MDR requirements.

C. FDA Registration (USA)

- Required for entering the U.S. market

- Includes:

- FDA Establishment Registration

- Device Listing (via 510(k) if applicable)

- Good Manufacturing Practices (GMP)

🔎 Verify manufacturer status on the FDA Establishment Registration & Device Listing database: https://www.accessdata.fda.gov

D. Other Global Standards

| Region | Regulatory Body | Standard/Requirement |

|---|---|---|

| Canada | Health Canada | Medical Device License (MDL) |

| Japan | PMDA | Pharmaceuticals and Medical Devices Act (PMD Act) |

| Australia | TGA | ARTG Listing |

| Brazil | ANVISA | INMETRO Certification |

E. Documentation Buyers Should Request

| Document Type | Purpose |

|---|---|

| ISO 13485 Certificate | Quality assurance for medical device production |

| CE Declaration of Conformity | Confirms EU regulatory compliance |

| FDA Establishment Registration | Confirms US market access |

| Biocompatibility Test Reports | Verifies safety of materials |

| Sterilization Validation Report | Confirms sterility and shelf-life |

| Product Technical File | Includes design, materials, and test results |

📎 Tip: Store all documentation in a centralized repository for audits, tenders, and re-certification.

9. FAQs: Common Questions About Biocompatibility in Medical Swabs & Brushes

Q1: What is the most biocompatible material for swab tips?

A: Flocked nylon is considered one of the most biocompatible materials for swab tips. It offers high absorption, quick elution, and is non-toxic, making it ideal for PCR and viral detection.

Q2: How can I verify if a swab or brush is biocompatible?

A: Ask for ISO 10993 test reports from the manufacturer. These include cytotoxicity, sensitization, and irritation test results.

Q3: Are cotton-tipped swabs biocompatible?

A: While cotton is naturally biocompatible, it may interfere with certain molecular tests due to oils or fibers. It’s suitable for general clinical use but not recommended for DNA/RNA testing.

Q4: Can I customize the swabs and brushes with my own brand?

A: Yes. Manufacturers like Jiangsu Hanheng offer OEM/ODM services, allowing private labeling and custom packaging.

Q5: What is the shelf life of sterile biocompatible swabs?

A: Typically 2–3 years when stored in a cool, dry, and sealed environment. Always check the expiration date on the packaging.

Q6: Do I need CE and FDA certification for swabs used in research only?

A: If used for clinical diagnostics, certifications are required. For research-only use, regulatory requirements may be less strict, but quality documentation is still recommended.

Q7: What are the lead times for bulk orders from China?

A: Lead times vary based on order size and customization. Jiangsu Hanheng typically offers:

- 7–10 days for repeat orders

- 15–20 days for custom OEM orders

Q8: What’s the minimum order quantity (MOQ)?

A: Hanheng offers flexible MOQs based on client needs, starting from as low as 1,000 units for OEM swabs.

Q9: How do I contact Jiangsu Hanheng for a quote or sample?

A: You can reach them via their official website or email:

🌐 Website: www.hanheng-medical.com

📩 Email: [email protected]

Final Thoughts & Call to Action

Biocompatibility is no longer optional—it is a mandatory requirement for any medical swab or brush used in clinical or diagnostic settings. For B2B buyers, ensuring that your products meet international safety and regulatory standards is essential to safeguarding patient health, maintaining brand integrity, and scaling your business globally.

Jiangsu Hanheng Medical Technology Co., Ltd. offers a comprehensive range of biocompatible medical consumables that combine innovation, precision manufacturing, and global compliance. Whether you’re a distributor, OEM client, or hospital procurement specialist, Hanheng is your trusted partner in delivering safe, certified, and high-performance swabs and sampling brushes.

📦 Ready to source biocompatible medical swabs and brushes?

👉 Visit www.hanheng-medical.com

📧 Email [email protected] to request samples, technical documents, or a custom quote.

Elevate your product line with precision-engineered consumables trusted by healthcare professionals worldwide. Let Hanheng help you build safer, smarter diagnostics.

Jiangsu Hanheng Medical Technology Co., Ltd.

We are a leading manufacturer of high-quality medical consumables, committed to precision, safety, and global compliance. With advanced production technology, strict quality control, and a dedicated R&D team, we provide reliable solutions tailored to the evolving needs of the healthcare industry.