Visão geral da fábrica

Fábrica de fabrico de precisão

Na Hanheng, nossas instalações de fabricação de última geração integram tecnologia de ponta, automação e controle de qualidade rigoroso para garantir os mais altos padrões da indústria. Desde a seleção de matérias-primas até à esterilização e embalagem finais, cada passo é optimizado para eficiência, precisão e fiabilidade.

Ao integrarmos automação de ponta e monitorização digital, melhoramos a precisão, a eficiência e a escalabilidade, garantindo consumíveis médicos de qualidade superior para prestadores de cuidados de saúde em todo o mundo.

Servir o mundo

120+ países.

A Hanheng possui uma capacidade de produção em larga escala, o que nos permite atender às demandas dos mercados globais de forma eficiente.

ODM&OEM

Apoio

Equipamentos e Tecnologia Hanheng

Para garantir o mais alto nível de precisão e eficiência, nossa instalação é equipada com uma gama completa de máquinas avançadas e sistemas de fabricação inteligentes.

Máquinas de Moldagem por Injeção

Produz cabos de swab, tubos e outros componentes plásticos médicos com precisão de nível micrométrico.

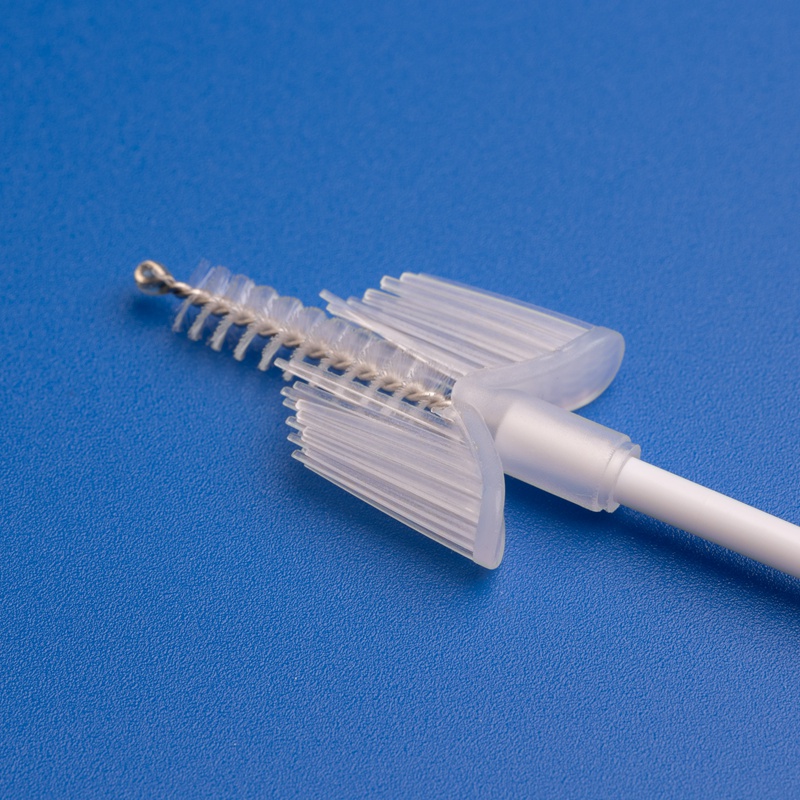

Equipamento de Flocking Automatizado

Utiliza tecnologia de flocking eletrostático para distribuir uniformemente as fibras nas pontas dos swabs, aumentando a retenção e a eficiência de liberação da amostra.

Montagem e Embalagem Inteligentes

As linhas de montagem robóticas de alta velocidade reduzem os riscos de contaminação, mantendo a consistência.

Câmaras de Esterilização EO

Equipadas com unidades de esterilização EO controladas com precisão, garantindo a eliminação de 99,99% de bactérias e vírus.

Produção em Sala Limpa Classe 100.000

Mantém um ambiente ultrassteril para evitar a contaminação durante a produção. Sistemas rigorosos de filtragem de ar garantem um ambiente controlado que cumpre as regulamentações de fabricação médica.

Processos Inovadores

Cada etapa do nosso processo de produção é cuidadosamente controlada para manter a consistência, eficiência e conformidade com os padrões médicos internacionais.

01

Seleção e Pré-Tratamento de Materiais

Adquirimos matérias-primas de alta qualidade de grau médico, inspecionando-as e tratando-as rigorosamente antes do processamento.

02

Moldagem e Fabricação de Precisão

Moldagem por injeção avançada e técnicas de corte de alta velocidade garantem dimensões uniformes e durabilidade.

03

Flocking e Revestimento Automatizados

Utilização de tecnologia eletrostática para adesão uniforme das fibras, melhorando a retenção de amostras em swabs.

04

Montagem e Inspeção de Qualidade

Montagem automatizada em várias etapas, seguida de monitoramento de qualidade em tempo real e detecção de defeitos.

05

Esterilização e Embalagem

Esterilização EO e embalagem hermética em um ambiente de sala limpa controlada para manter a esterilidade do produto.

Nossa Equipe: Experiência e Dedicação

Na Hanheng, nossa equipe é construída com base em experiência, precisão e inovação. Reunimos profissionais qualificados em produção, pesquisa e controle de qualidade, garantindo os mais altos padrões na fabricação de consumíveis médicos.

Equipe de Produção

Técnicos e engenheiros experientes supervisionam a fabricação automatizada, moldagem de precisão e monitoramento de processos em tempo real, garantindo eficiência e consistência.

Equipe de P&D

Especialistas em ciência de materiais e bioengenharia se concentram na inovação de produtos, design ergonômico e otimização de desempenho para atender às necessidades em evolução do setor.

Equipe de Controle de Qualidade

Especialistas implementam inspeções rigorosas e protocolos de teste para manter os rigorosos padrões internacionais.

Qualidade e Conformidade Líderes do Setor

Na Hanheng, aderimos aos mais rigorosos padrões médicos globais, garantindo que nossos processos de fabricação atendam e superem os parâmetros de referência do setor. Nossa fábrica opera sob certificações reconhecidas internacionalmente

ISO 13485

Garante o controle de qualidade rigoroso em design, produção, distribuição e serviço.

CE

Confirma a conformidade com os padrões de saúde, segurança e meio ambiente da EEA.

Conformidade com as BPF

Garante condições de fabricação seguras e higiênicas.

Registro da FDA

Verifica a segurança e eficácia de dispositivos médicos para o mercado dos EUA.

Nosso sistema de controle de qualidade em tempo real monitora continuamente os parâmetros de produção, detectando anomalias e fazendo ajustes instantâneos para evitar defeitos.