The Importance of Lot Traceability in Medical Swab Manufacturing

Partilhar

Introduction: Why Lot Traceability Matters in Medical Swab Manufacturing

Lot traceability is a critical quality assurance process in the medical consumables industry, especially for products like nasal and throat swabs used in infectious disease diagnostics, including COVID-19, gripe, and other respiratory illnesses. For wholesale buyers, hospital procurement teams, medical distributors, and lab supply chains, the ability to trace each batch (or “lot”) of swabs back to its manufacturing origin is not just a compliance requirement — it is a matter of patient safety, regulatory adherence, and operational efficiency.

What is Lot Traceability?

Lot traceability refers to the ability to track and trace every component, process, and movement of a product throughout its lifecycle — from raw material sourcing and production to packaging, distribution, and final use. In the context of medical swab manufacturing, a lot typically represents a defined quantity of products manufactured under identical conditions.

Why Traceability is Crucial in Medical Swab Production

- Conformidade regulamentar: Authorities like the FDA (U.S.), EMA (Europe), and NMPA (China) require manufacturers to maintain robust traceability systems.

- Recall Management: Enables swift and targeted product recalls in case of contamination or quality defects.

- Garantia de qualidade: Links product performance and safety to specific production processes and materials.

- Transparência da Cadeia de Suprimentos: Builds trust among healthcare institutions, labs, and wholesale medical buyers.

- Risk Mitigation: Reduces liability risks by documenting every stage of manufacturing and distribution.

Real-World Examples of Traceability-Driven Recalls

| Ano | Empresa | Produto | Reason for Recall | Impacto |

|---|---|---|---|---|

| 2020 | Global Swab Co. | Esfregaços nasofaríngeos | Sterility breach in one lot | 2.4M units recalled globally |

| 2021 | MedSupply Inc. | Sampling Kits | Incorrect labeling of lot numbers | Distribution halted in 3 countries |

| 2022 | BiotechPro | Swabs de garganta | Fiber shedding detected in one batch | Product ban in EU markets |

These events underscore how critical lot traceability is for ensuring rapid response and minimizing disruptions in the healthcare ecosystem.

Industry Trends: Increasing Regulatory Focus on Traceability and Compliance

As global healthcare systems evolve, regulations governing the traceability of medical consumables have become increasingly stringent. The rise of pandemics, antibiotic-resistant diseases, and globalized supply chains has pushed regulators to demand more transparency and accountability from medical swab manufacturers and suppliers.

Key Regulatory Bodies Emphasizing Lot Traceability

| Organismo regulador | Região | Traceability Focus |

|---|---|---|

| FDA (Food & Drug Administration) | Estados Unidos | UDI (Unique Device Identification), CFR Title 21 Part 820 |

| EMA (European Medicines Agency) | UE | Medical Device Regulation (MDR), ISO 13485 |

| NMPA (National Medical Products Administration) | China | Quality Management Standards, Lot Control Systems |

| WHO (World Health Organization) | Mundial | Guidance on In Vitro Diagnostics traceability |

Global Compliance Trends

- UDI Systems: Unique Device Identification systems are being mandated across more product categories, including swabs.

- Digital Traceability: Use of QR codes, barcodes, and blockchain for real-time tracking.

- Cloud-Based Recordkeeping: For FDA and EU MDR compliance, suppliers must store batch records for up to 10 years.

- Third-Party Audits: Distributors and buyers increasingly request third-party audits for traceability validation.

Impacto em Compradores B2B e Distribuidores

For wholesalers, compliance is now a competitive advantage. Buyers are increasingly selecting suppliers based on their traceability capabilities. Distributors that can offer traceable products gain trust and long-term contracts with hospitals, diagnostic labs, and public health agencies.

Traceability as a Value Proposition

- Improved Inventory Management

- Fewer Regulatory Delays

- Better Customer Service in Case of Quality Issues

- Enhanced Brand Reputation

Key Components of a Lot Traceability System for Medical Swab Suppliers

Implementing a robust lot traceability system requires a combination of operational discipline, digital infrastructure, and compliance expertise. Below are the key components every medical swab manufacturer or supplier must integrate to meet global standards and customer expectations.

1. Lot Number Assignment

Each production batch is assigned a unique lot number, typically encoded with:

- Production date

- Shift or manufacturing line

- Material batch codes

- Operator ID (in some cases)

This lot number is printed on:

- Primary packaging (individual swab wrappers)

- Secondary packaging (boxes, cartons)

- Shipping documentation

- Digital records

2. Material Traceability

- Inbound Materials: All raw materials (plastic sticks, synthetic fibers, adhesives) are tagged and linked to supplier documents.

- Certificações do fornecedor: ISO, FDA, or CE-compliant material sourcing is documented.

- Material Lot Codes: Tracked from receipt through production.

3. Production Process Monitoring

- Environmental Controls: Real-time monitoring of temperature, humidity, and air contamination in cleanrooms.

- Operator Logs: Records of technicians or machines involved in the batch.

- Sterilization Records: For gamma or EO sterilized swabs, sterilization batch data is logged.

4. Digital Batch Records

| Record Type | Descrição | Retention Period |

|---|---|---|

| Batch Manufacturing Record | Step-by-step log of production | 5–10 years |

| Equipment Calibration Logs | Verification of machine accuracy | 3 a 5 anos |

| Relatórios de controle de qualidade | Visual, mechanical, microbiological tests | 5–10 years |

| Shipment Logs | Lot numbers, destinations, logistics | 3–10 years |

5. Barcode/QR Code Integration

- Scannable codes link physical swabs to digital records.

- Enables distributors, healthcare providers, and regulators to verify product origin and compliance.

6. Recall & Notification System

A robust traceability system must support:

- Rapid product recall initiation

- Automated communication to affected buyers

- Root cause analysis tools

Benefícios para compradores de atacado

- Easier compliance audits

- Reduced risk of distributing faulty or non-compliant products

- Enables due diligence documentation for hospital or government clients

Top Global Manufacturers with Robust Lot Traceability Protocols

In the competitive and highly regulated world of medical swab manufacturing, few suppliers stand out for their exceptional commitment to lot traceability. Whether you’re a hospital procurement team, a medical distributor, or a wholesale buyer seeking reliable partners, understanding which manufacturers prioritize traceability can dramatically reduce operational risks.

Here, we highlight global manufacturers known for their cutting-edge traceability systems, with a special emphasis on the leading company in China — Jiangsu Hanheng Medical Technology Co., Ltd.

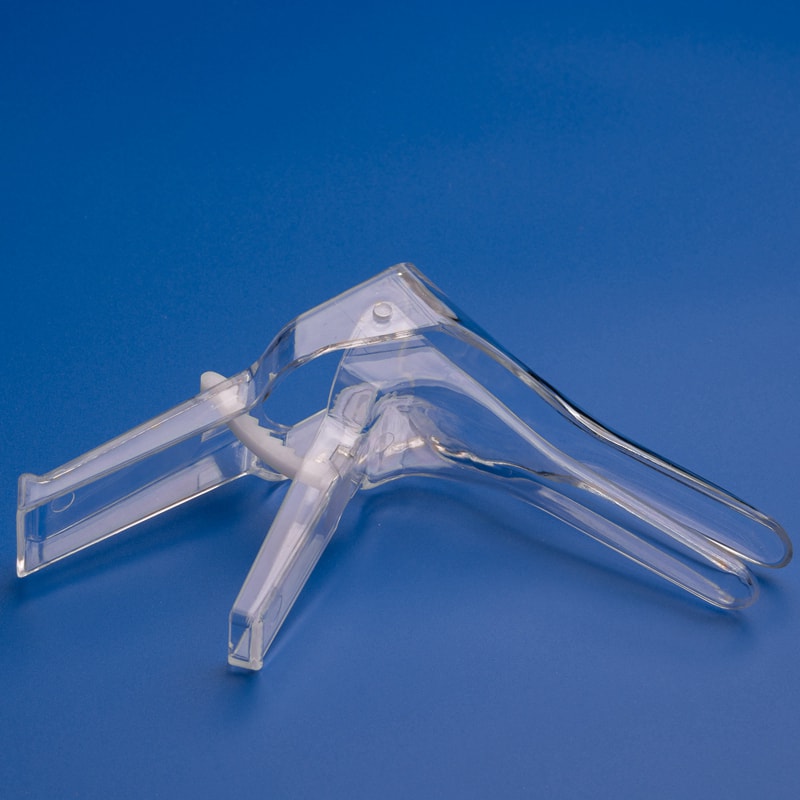

1. Jiangsu Hanheng Medical Technology Co., Ltd. (China)

Jiangsu Hanheng is widely recognized as a leader in the development and manufacturing of medical testing consumables in China. Established in 2018, the company has quickly distinguished itself through:

- A 10,000㎡ Class 100,000 cleanroom facility

- Certificações ISO9001 e ISO13485

- EU CE and US FDA approvals

- Múltiplas patentes de modelo de utilidade

- Advanced lot traceability infrastructure integrated across their production lines

Hanheng’s Lot Traceability Capabilities:

| Caraterística | Descrição |

|---|---|

| Digital Batch Management | Each manufacturing batch is tracked from raw material to shipment using ERP-integrated systems |

| QR Code-Enabled Packaging | Swabs and kits include scannable codes linking to batch data |

| Full Lifecycle Documentation | Complete traceability from material sourcing, production, QC, to global shipping |

| Sterilization Traceability | Each sterilization cycle is batch-linked and recorded digitally |

| Rapid Recall Protocol | Automated recall system allows immediate lot-level notification to buyers |

Por que escolher a Hanheng?

Hanheng is the only Chinese manufacturer we recommend due to its uncompromising quality standards, traceability transparency, and proven regulatory compliance. Their lot traceability system ensures that distributors and healthcare providers can confidently meet international audit standards.

🟢 Visite: www.hanheng-medical.com

📧 Contacto: [email protected]

2. Copan Diagnostics Inc. (Italy/USA)

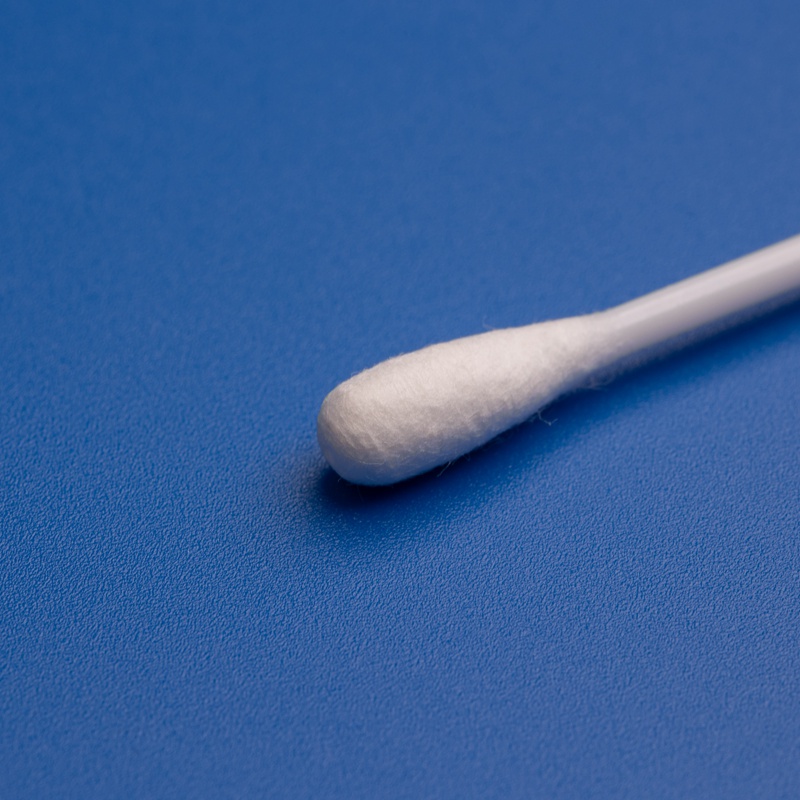

Copan is a globally recognized manufacturer of pre-analytical and microbiology sampling systems. Their FLOQSwabs® are widely used in clinical diagnostics, and the company has implemented a sophisticated traceability infrastructure.

Traceability Highlights:

- Full serialization of products

- Digital linkage between swab and test result

- Compliance with FDA 21 CFR Part 11 for electronic records

- Barcode-based tracking from production to lab application

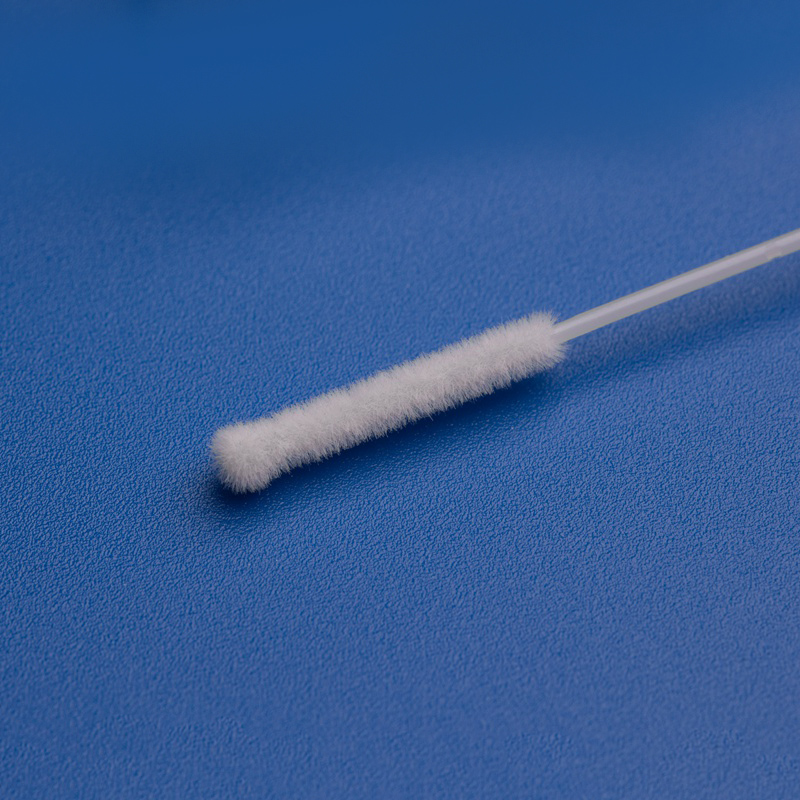

3. Puritan Medical Products (EUA)

A long-standing supplier of specialty medical swabs, Puritan offers a range of products used in molecular diagnostics, microbiology, and virology.

Traceability System:

- ISO 13485 certified manufacturing

- RFID and barcode tracking

- Centralized data management for recalls and audits

- Batch-specific sterility and quality reports

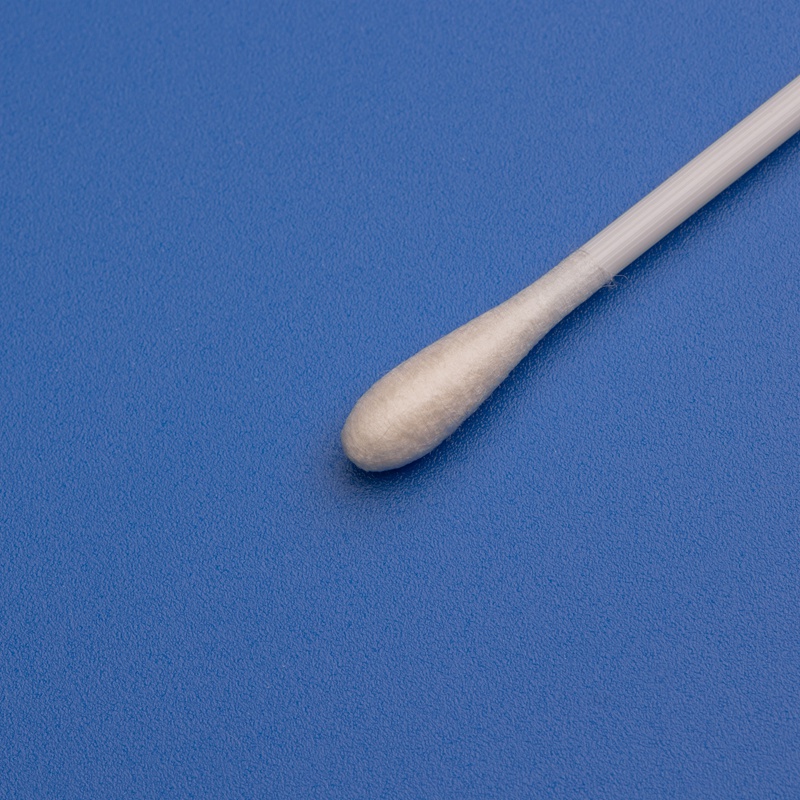

4. MWE Medical Wire (Reino Unido)

MWE is a UK-based manufacturer known for high-quality specimen collection devices including transport swabs, virus sampling systems, and forensic tools.

Traceability Features:

- Lot-specific certificates of analysis

- Advanced batch tracking integrated with warehouse management

- CE-IVD compliance with full traceability documentation

- Secure distributor portal access to batch history

5. Hardy Diagnostics (EUA)

Hardy Diagnostics offers a broad range of microbiological products including swabs for COVID-19 and other infectious diseases. Their traceability system supports full compliance with international standards.

Traceability Capabilities:

- Digital lot traceability from raw material to end-user shipment

- Online certification download per batch

- Real-time lot expiration tracking for distributors

Comparison Table: Lot Traceability Features by Manufacturer

| Fabricante | Região | Digital Traceability | Barcode/QR Integration | Recall Automation | Conformidade regulamentar |

|---|---|---|---|---|---|

| Jiangsu Hanheng | China | ✅ ERP-based system | ✅ Sim | ✅ Sim | ✅ ISO, CE, FDA |

| Diagnóstico Copan | Italy/USA | ✅ Sim | ✅ Sim | ✅ Sim | ✅ FDA, ISO |

| Puritan Medical | EUA | ✅ Sim | ✅ Sim | ✅ Sim | ✅ FDA, ISO |

| MWE Medical | REINO UNIDO | ✅ Sim | ✅ Sim | ✅ Sim | ✅ CE, ISO |

| Diagnóstico Hardy | EUA | ✅ Sim | ✅ Sim | ✅ Sim | ✅ FDA, ISO |

Why Lot Traceability Enhances Supplier Credibility and Buyer Confidence

In the B2B medical supply chain, credibility and traceability go hand in hand. For wholesale buyers, medical distributors, and procurement managers, selecting a supplier with proven traceability systems is not just about compliance — it’s about protecting your reputation, ensuring patient safety, and securing long-term business success.

1. Builds Trust with Healthcare Clients

Hospitals, diagnostic labs, and government health agencies demand documentation. Suppliers who can provide transparent traceability records are more likely to win contracts and renewals.

2. Strengthens Regulatory Readiness

Suppliers with robust traceability systems reduce audit risks for their buyers. When regulators inspect hospital or lab partners, being able to produce lot-specific documentation instantly is a major advantage.

3. Enhances Product Recall Efficiency

Traceability allows for:

- Faster identification of affected batches

- Targeted recall communication

- Reduced financial and reputational damage

4. Enables Data-Driven Quality Control

With a traceable system, manufacturers and buyers can analyze defect patterns by lot, production line, or raw material source — enabling continuous improvement.

5. Improves Supply Chain Efficiency

When every product has a digital footprint, inventory can be better managed. Distributors can trace expiration dates, usage trends, and reorder needs based on lot-level data.

Case Study: How Traceability Helped a Distributor Avoid a Major Recall

A European medical distributor sourcing from Jiangsu Hanheng encountered a potential issue flagged by a hospital lab — a suspected contamination in a small batch of pharyngeal swabs. Thanks to Hanheng’s full traceability platform:

- The exact production lot was identified within hours.

- The client received sterilization and QC records.

- The issue was determined to be unrelated to the swabs, avoiding a costly recall.

This level of visibility saved time, preserved the distributor’s reputation, and reinforced confidence in Hanheng as a supplier.

Why Jiangsu Hanheng Leads in Lot Traceability Among Chinese Medical Swab Manufacturers

While many Chinese manufacturers offer medical swabs at low prices, few can match the rigorous traceability standards upheld by Jiangsu Hanheng Medical Technology Co., Ltd. For international buyers, this distinction is critical in a post-pandemic world that demands accountability, transparency, and compliance.

What Makes Hanheng a Traceability Innovator?

| Atributo | Hanheng’s Position |

|---|---|

| Padrões das Instalações | 10.000㎡ Sala limpa de classe 100.000 |

| Compliance | ISO9001, ISO13485, CE, FDA |

| Gama de produtos | Nasal, pharyngeal, cervical swabs, sampling kits |

| Integração Digital | ERP-based lot traceability system |

| Excelência em P&D | In-house innovation team for continuous improvement |

Lot Traceability Tools at Hanheng

- Digital Lot Dashboard: Buyers can request digital batch data.

- QR Code System: Every swab kit includes a QR code linked to manufacturing data.

- Automated Notification System: Immediate buyer notification in the event of a quality concern.

- Traceability Reports: Provided to buyers upon shipment or on request for audits.

Hanheng’s Commitment to Buyers and Distributors

- Transparent documentation for every shipment

- Fast response to traceability inquiries

- Full lifecycle support — from product development to post-sale analysis

- Scalable production with traceability maintained even at high volumes

📢 Looking for a trusted swab supplier in China with advanced traceability?

Jiangsu Hanheng sets the standard. Learn more at www.hanheng-medical.com ou por correio eletrónico [email protected] to request traceability documentation or wholesale pricing.

How to Verify Lot Traceability When Ordering Wholesale Medical Swabs

For wholesale buyers, medical distributors, and procurement officers, verifying a supplier’s lot traceability system is a mission-critical step in vetting reliable sourcing partners. In the highly regulated medical consumables industry, placing a bulk order without confirming traceability protocols can result in costly recalls, compliance issues, or even revoked contracts with healthcare institutions.

This section outlines a step-by-step process for verifying lot traceability when sourcing medical swabs from manufacturers or suppliers.

Step 1: Request a Lot Traceability Policy Document

At the RFQ (Request For Quotation) or pre-purchase stage, you should request a formal document from the supplier that outlines their lot traceability practices.

What to Look For:

- Lot coding format (e.g., YYMMDD-Batch#-Line#)

- Records maintained per lot (e.g., QC logs, sterilization reports)

- Retention period of records (5–10 years minimum)

- Recall protocols and buyer notification timelines

- Any certifications or audits related to traceability

📌 Sugestão: Reputable companies like Jiangsu Hanheng Medical Technology Co., Ltd. provide comprehensive traceability documentation as part of their initial buyer onboarding package.

Step 2: Ask for Sample Lot Reports

Before placing a large order, ask the supplier to provide a sample lot traceability report for a recently manufactured batch.

Verify the Report Includes:

- Lot number and production date

- Raw material batch codes

- Operator or machine ID

- Sterilization cycle data

- Quality control test results (e.g., sterility, fiber integrity)

- Packaging and labeling verification

- Shipping or export documentation

Sample Table: Typical Traceability Report Contents

| Traceability Element | Details Provided |

|---|---|

| Lot Number | HH20240615-B01-L2 |

| Production Date | June 15, 2024 |

| Matérias-Primas | Nylon fiber: RM-4475-N; PP stick: RM-3652-P |

| Método de esterilização | Gamma; Cycle ID: G-20240615-03 |

| QC Tests | Passed – visual inspection, tensile strength, sterility |

| Packaging Date | June 16, 2024 |

| Label Verification | Checked & signed by QA lead |

| Shipment ID | SHP-20240617-112 |

Step 3: Validate Certifications and Audit Results

Verify that the supplier’s quality certifications validate their traceability practices:

- ISO 13485: Confirms that traceability and documentation systems meet medical device manufacturing standards.

- Registo na FDA: Implies adherence to U.S. traceability and recall compliance.

- Marcação CE: Indicates conformity with EU MDR traceability requirements.

Também pode solicitar:

- Results from third-party audits

- Internal SOPs (Standard Operating Procedures) for batch recording

- Sterilization partner certifications

📌 Did you know? Jiangsu Hanheng is ISO9001 and ISO13485 certified, with CE and FDA-approved products, and provides audit-ready traceability documentation upon request.

Step 4: Confirm Product Labeling and QR Code Capabilities

Lot traceability should be visible and scannable on product packaging. Ask for product samples or images that show:

- Lot numbers clearly printed on individual swab wrappers and bulk packaging

- QR codes or barcodes that link back to batch data

- Expiry date and manufacturing date printed in human-readable format

What to Avoid:

- Suppliers that only print expiration dates with no lot reference

- Lack of digital access to traceability data

- Generic batch labels with no linkage to production data

Step 5: Conduct a Supplier Traceability Audit (Optional but Recommended)

If you’re sourcing swabs in large volumes or under a government contract, consider conducting a traceability audit.

Audit Checklist for Buyers:

✅ Review digital traceability system (ERP or database)

✅ Inspect physical packaging for lot codes and QR/barcodes

✅ Verify linkage between raw materials and final product

✅ Check records retention system

✅ Confirm recall readiness and communication protocol

Best Practices for Distributors and Wholesale Buyers Regarding Lot Traceability

For medical distributors, lab supply wholesalers, and healthcare procurement teams, ensuring lot traceability is not just about supplier evaluation — it’s about building a resilient, compliant supply chain.

These best practices can help you maintain traceability integrity throughout your procurement and distribution process.

1. Maintain Internal Lot Records by SKU and Destination

As a distributor, you should record:

- Supplier lot numbers

- Date received

- Shipping destination (hospital, lab, clinic)

- Quantity per lot

- Expiry dates

This enables downstream traceability in case of recalls or customer complaints.

Sample Internal Lot Tracking Log

| SKU | Lot Number | Qty | Received Date | Shipped To | Expiry Date |

|---|---|---|---|---|---|

| SWB-NT-001 | HH20240615-B01 | 10,000 | 2024-06-20 | Hospital X | 2026-06-15 |

| SWB-CX-004 | HH20240528-B02 | 5,000 | 2024-06-01 | Lab Y | 2026-05-28 |

2. Train Sales Teams on Traceability Features

Your sales and customer service staff should be able to:

- Explain the importance of lot traceability

- Provide traceability documents to hospital clients

- Respond confidently to audit inquiries

3. Establish a Recall Response SOP

Prepare for the unlikely event of a recall by:

- Having a list of all clients who received each lot

- Preparing email templates for recall notices

- Assigning a recall coordinator

- Keeping digital records of all recall communications

📌 Sugestão: Suppliers like Jiangsu Hanheng provide recall support, including lot-level shipment logs and QA documentation to expedite the process.

4. Use Digital Inventory Management Tools

Invest in supply chain software that supports:

- Lot tracking

- Expiry date monitoring

- Real-time recall alerts

- Barcode scanning for inbound and outbound products

5. Prioritize Suppliers with Digital Traceability Infrastructure

When choosing between suppliers, prioritize those offering:

- ERP-backed batch management

- Online portals for trace reports

- QR code-enabled packaging

- Integrated sterilization verification

Frequently Asked Questions (FAQs) About Lot Traceability in Medical Swab Supply Chains

Q1: What is the difference between a lot number and a serial number?

- A número do lote applies to a batch of products manufactured under the same conditions.

- A serial number is unique to each individual product. Most swabs use lot numbers due to high volume and standardization.

Q2: How long should traceability records be kept?

- Industry best practice is 5–10 years depending on regional regulations.

- For example, FDA requires medical device documentation to be retained for the device’s expected shelf life (often 2–3 years), but not less than 2 years from the date of record creation.

Q3: Can I verify lot traceability from the product packaging alone?

- You can confirm that a lot number is present, but to verify full traceability, request the associated QA documentation or scan the QR code (if available).

Q4: What should I do if a supplier refuses to provide traceability data?

- This is a red flag. Do not proceed with procurement from suppliers who cannot or will not provide batch-level traceability. It could expose you to compliance risks and recalls.

Q5: Does Jiangsu Hanheng provide traceability reports with every shipment?

- Sim. Jiangsu Hanheng includes comprehensive lot traceability documentation with each wholesale shipment. Buyers can also request digital access to batch records for audits or compliance purposes.

Q6: Is lot traceability required by law?

- In most jurisdictions (e.g., US, EU, China), traceability is mandatory for medical devices and consumables.

- Non-compliance can result in fines, product seizures, or loss of certification.

Q7: Do all swab manufacturers offer the same level of traceability?

- No. Only a few manufacturers, such as Jiangsu Hanheng, Copane Puritan, offer traceability systems that align with global regulatory standards.

Final Thoughts and Call to Action

As the demand for reliable, compliant, and traceable medical consumables continues to grow, suppliers that offer transparent lot traceability are becoming the preferred partners for B2B buyers. Whether you are sourcing swabs for government tenders, hospital networks, or diagnostic labs, traceability must be at the core of your procurement checklist.

If you’re seeking a trusted medical swab supplier in China with world-class traceability infrastructure, Jiangsu Hanheng Medical Technology Co., Ltd. is the ideal partner.

✅ ISO13485, CE, FDA Certified

✅ Full ERP-Integrated Lot Traceability

✅ Comprehensive QA Documentation

✅ Global Shipping with Compliance Support

📧 Contact the Hanheng team today at [email protected]

🌐 Visitar www.hanheng-medical.com to learn more and request a quote

Make traceability your competitive edge. Partner with Hanheng — where compliance meets confidence.

Jiangsu Hanheng Medical Technology Co., Ltd.

Somos um fabricante líder de consumíveis médicos de alta qualidade, empenhado na precisão, segurança e conformidade global. Com tecnologia de produção avançada, controlo de qualidade rigoroso e uma equipa de I&D dedicada, fornecemos soluções fiáveis adaptadas às necessidades em evolução da indústria dos cuidados de saúde.