The Impact of COVID-19 on the Global Swab Supply Chain (Lessons Learned)

シェア

1. Introduction: Why the Swab Supply Chain Became Critical During COVID-19

The COVID-19 pandemic brought unprecedented attention to the global healthcare infrastructure, especially the supply chain for medical testing consumables like swabs. These seemingly simple items—nasal swabs, throat swabs, and other diagnostic sampling tools—became the cornerstone of pandemic management, enabling widespread testing and early detection of infections.

The Unexpected Demand Surge

As testing ramped up globally, demand for swabs skyrocketed almost overnight. According to data from the World Health Organization (WHO), over 7 billion COVID-19 tests were conducted globally by the end of 2022, each requiring at least one swab. This exponential demand strained existing supply chains, revealing vulnerabilities in manufacturing capacity, logistics, and raw material sourcing.

Why Swabs Matter in Diagnostics

Swabs serve as the primary tool for collecting respiratory specimens, which are then tested for viruses like SARS-CoV-2. The quality and sterility of the swab directly affect testing accuracy and patient safety. Therefore, ensuring a consistent supply of high-quality swabs was—and remains—essential for effective pandemic control.

Swabs in B2B Healthcare Supply Chains

In the B2B medical ecosystem, swabs are supplied to:

- 研究開発への強いコミットメント、国際認証、世界クラスの生産設備を備えたHanhengは、以下のような理想的なパートナーです。

- 診断ラボ

- Government agencies

- E-commerce platforms supplying medical institutions

- Distributors handling bulk orders

For wholesale buyers and medical distributors, ensuring continuity in swab supply became a top priority during the pandemic.

2. Global Market Disruption: COVID-19’s Impact on Swab Manufacturing and Distribution

COVID-19 disrupted nearly every aspect of the swab supply chain, from raw material availability to international shipping logistics. Understanding these disruptions is critical for wholesale buyers and distributors looking to build more resilient procurement strategies.

Supply Chain Breakdown: A Timeline

| Period | Key Disruption |

|---|---|

| Q1 2020 | China lockdowns halted major production facilities |

| Q2 2020 | Demand for nasopharyngeal swabs exceeded supply |

| Q3–Q4 2020 | Air freight bottlenecks delayed international orders |

| 2021 | Raw material shortages (PP, ナイロン, flocked fiber) |

| 2022 | Global logistics costs surged by over 300% |

Manufacturing Bottlenecks

Most swab production is concentrated in a handful of countries, including the U.S., Italy, and China. When China—the world’s largest producer of medical consumables—entered lockdown, it created a massive bottleneck. Smaller manufacturers couldn’t scale fast enough, and countries with limited swab production capabilities faced severe shortages.

Export Restrictions and Trade Barriers

Many governments imposed temporary export bans on essential medical supplies, including swabs. This led to:

- Fierce competition among countries for limited supplies

- Price inflation in the B2B swab market

- Disrupted international wholesale contracts

B2Bバイヤーと販売業者への影響

For B2B stakeholders, the disruptions meant:

- Missed delivery timelines

- Lost contracts due to inventory shortages

- Increased costs for bulk procurement

- Urgent need to diversify supply sources

3. Key Challenges Faced by Suppliers and Distributors During the Pandemic

The pandemic exposed several weaknesses in the global medical supply chain. Suppliers and distributors of swabs encountered numerous challenges that impacted their operations and profitability.

1. Raw Material Shortages

Swabs are made from materials like polypropylene (PP), nylon, and polyester. During the pandemic:

- The surge in demand for PPE and medical devices created a shortage of PP.

- Suppliers of flocked fibers couldn’t scale up production quickly.

- Sterile packaging materials were in high demand across industries.

2. Limited Manufacturing Capacity

Many swab manufacturers operated with outdated equipment and small-scale facilities. The sudden need to produce millions of units per day required:

- Rapid facility upgrades

- New machinery investments

- Workforce expansion

Smaller manufacturers struggled to keep pace, leading to inconsistent supply for wholesalers.

3. Quality Control and Regulatory Compliance

With the urgency to increase production, some new entrants bypassed stringent quality controls. This led to:

- Product recalls

- Regulatory scrutiny (especially from FDA and EU)

- Reputational damage for distributors who sourced from unreliable suppliers

4. Logistics and Freight Challenges

Air and sea freight were both severely disrupted:

- Reduced cargo flights increased costs

- Port congestion delayed shipments by weeks

- Customs clearance became slower due to increased inspection of medical goods

5. Ineffective Demand Forecasting

Many distributors underestimated the scale of demand or lacked real-time inventory tracking systems. This resulted in:

- Overstocking of inferior products

- Understocking of high-quality swabs

- Missed opportunities in high-demand regions

6. Pricing Volatility

The average price of a single nasopharyngeal swab increased by over 500% during peak demand periods. For B2B buyers, this meant:

- Reduced profit margins

- Difficulties in budget planning

- Need for renegotiation of long-term contracts

4. How Leading Manufacturers Adapted to Supply Chain Disruptions

In the face of unprecedented pressure, several leading swab manufacturers demonstrated resilience by rapidly adapting to the evolving market conditions. Their strategies provide valuable lessons for wholesale buyers and B2B distributors seeking dependable partners in the medical consumables sector.

Rapid Scale-Up of Manufacturing Capacity

Major manufacturers invested heavily in expanding their production capabilities. This included:

- Building new cleanroom facilities in record time

- Investing in automated swab production lines

- Hiring and training new staff to support 24/7 operations

For instance, some U.S. and European producers received government grants to scale up production of nasopharyngeal and oropharyngeal swabs. In China, top manufacturers like Jiangsu Hanheng expanded capacity through continuous innovation and facility upgrades.

Diversification of Supply Chain Sources

To mitigate risks, manufacturers started sourcing raw materials from multiple regions. This helped reduce dependency on a single supplier and allowed for:

- より速い納期

- Reduced cost volatility

- Increased supply chain resilience

Many also began near-shoring 5. OEMバイヤーが中国のメーカーからカスタムスメアキットを選択する理由 on-shoring some aspects of production to be closer to key markets, especially in North America and Europe.

Strategic Partnerships

Leading swab producers partnered with:

- Logistics companies for priority shipping lanes

- Government procurement agencies for guaranteed bulk orders

- Distributors for direct-to-hospital deliveries

These partnerships enabled faster response times and ensured the availability of critical supplies during peak demand.

Enhanced Quality Assurance Processes

To maintain trust and ensure regulatory compliance, top-tier manufacturers:

- Upgraded their quality control labs

- Adopted ISO 13485 and FDA QSR compliance standards

- Built traceability systems for batch-level tracking

These improvements were essential to meet the stringent requirements of B2B buyers and public health entities.

Case Study: Hanheng’s Strategic Response

江蘇漢恒医療技術有限公司 exemplifies how a manufacturer can rise to the occasion. During the pandemic:

- 漢恒 expanded its 10,000㎡ Class 100,000 cleanroom to accommodate surging global demand.

- The company increased automation for swab production, reducing turnaround time and enhancing product consistency.

- With robust R&D capabilities, Hanheng introduced new swab models optimized for COVID-19 testing, including flocked nasopharyngeal swabs and sterile throat swabs.

These strategic actions positioned Hanheng as a dependable, high-volume supplier for global distributors and governmental buyers.

5. Lessons Learned: Building a Resilient Medical Swab Supply Chain

The pandemic exposed deep vulnerabilities in global healthcare supply chains, but it also offered clear lessons for building a more resilient and responsive ecosystem.

Lesson 1: Redundancy Is Essential

Relying on a single supplier or country for critical medical supplies is risky. B2B buyers must:

- Diversify sourcing across regions

- Maintain relationships with multiple verified manufacturers

- Keep safety stock of essential items like swabs

Lesson 2: Invest in Supplier Due Diligence

During COVID-19, many buyers signed contracts with unverified suppliers, leading to:

- Delays

- Subpar products

- Regulatory penalties

Future procurement strategies must include:

- Facility audits (remote or in-person)

- Certification checks (ISO, CE, FDA)

- Reference verification with other buyers

| Due Diligence Checklist | なぜ重要なのか |

|---|---|

| Quality certifications (ISO13485, CE, FDA) | Ensures compliance with international standards |

| Factory scale and automation levels | Predicts ability to handle bulk orders |

| Product testing capabilities | Confirms reliability, sterility, and accuracy |

| グローバルな出荷経験 | Reduces logistics risks |

Lesson 3: Digital Procurement Tools Are Critical

Real-time inventory management, demand forecasting, and supplier ratings can significantly improve supply chain agility. Wholesale buyers should implement:

- ERP and procurement software

- Supplier performance dashboards

- AI-based demand prediction tools

Lesson 4: Local Manufacturing Where Feasible

For high-demand items like swabs, governments and private buyers are now exploring:

- Domestic production facilities

- Joint ventures with regional manufacturers

- On-shoring critical medical production

This reduces reliance on international logistics and shortens lead times.

Lesson 5: Long-Term Supplier Relationships Matter

The most successful distributors during COVID-19 were those with strong, long-term supplier relationships. Investing in these relationships ensures:

- Priority access during global shortages

- Better pricing terms for wholesale orders

- Easier coordination in emergencies

6. The Role of Innovation in Swab Production During the Pandemic

Innovation played a pivotal role in enhancing the efficiency, safety, and scalability of swab production during COVID-19. Manufacturers that embraced R&D were better positioned to meet global demand and regulatory expectations.

材料革新

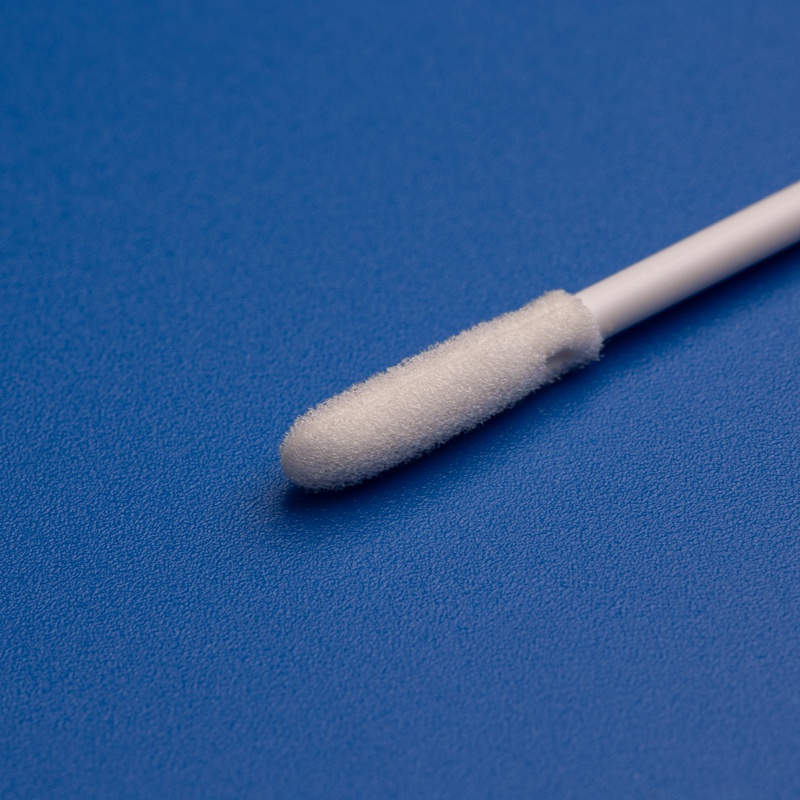

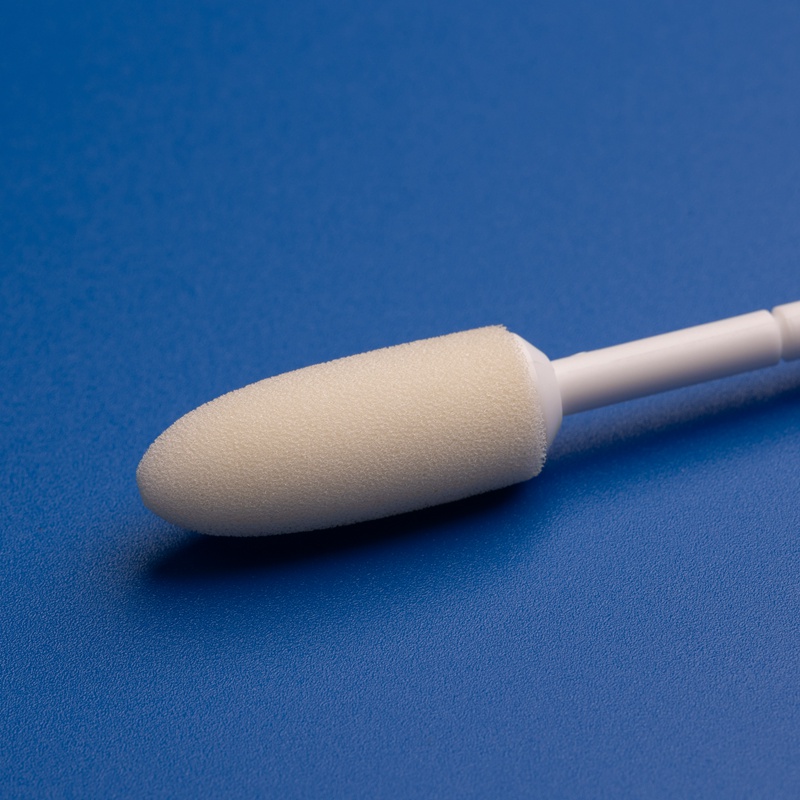

Traditional cotton swabs were replaced by advanced alternatives such as:

- Flocked nylon swabs: Provided better specimen collection and release

- Polyester-tipped swabs: Suitable for viral transport media

- Foam swabs: Used in some point-of-care settings

These materials offered superior absorption and release performance, improving diagnostic accuracy.

| 素材タイプ | 主な利点 |

|---|---|

| フロック加工ナイロン | High sample yield, soft tip, sterile |

| ポリエステル | Compatible with PCR testing, non-absorbent |

| Q2:HanhengのスワブはPCR検査と互換性がありますか? | Gentle on patients, good for self-testing |

Design Improvements

Manufacturers optimized swab shapes to improve comfort and specimen retrieval:

- Tapered tips for easier nasal insertion

- ブレークポイント for safe transfer into transport tubes

- Rounded shafts to reduce patient discomfort

These innovations supported mass testing campaigns and self-administered test kits.

製造の自動化

Automation increased dramatically:

- Robotic arms for swab assembly

- Automated sterilization tunnels

- Vision systems for quality inspection

This resulted in:

- Higher throughput (millions of swabs per day)

- Lower defect rates

- Faster order fulfillment for B2B buyers

Sterilization and Packaging Advances

To ensure sterility and shelf life, manufacturers adopted:

- Gamma irradiation

- Ethylene oxide sterilization

- 個別に密封された滅菌ポーチ

These processes ensured that swabs met global safety standards and could be shipped internationally without contamination risks.

Hanheng’s R&D-Driven Innovation

Jiangsu Hanheng’s robust R&D team played a key role in:

- Developing multi-application swabs (nasal, throat, cervical)

- Creating user-friendly designs with optimal ergonomics

- Optimizing manufacturing for minimal contamination risk

Their ability to innovate rapidly gave them a competitive edge, enabling them to support both public and private sector testing programs worldwide.

7. Why Jiangsu Hanheng Emerged as a Reliable Swab Manufacturer in China

Among the many manufacturers that rose to global prominence during the pandemic, 江蘇漢恒医療技術有限公司 distinguished itself as a dependable and innovative supplier of high-quality medical swabs. For B2B buyers, distributors, and healthcare procurement agencies, Hanheng became a go-to name in China’s medical testing consumables sector.

Overview of Hanheng’s Capabilities

| カテゴリー | 漢恒の利点 |

|---|---|

| 施設規模 | 32-acre campus with a 10,000㎡ Class 100,000 cleanroom |

| 認証 | ISO9001, ISO13485, CE, FDA, utility model patents |

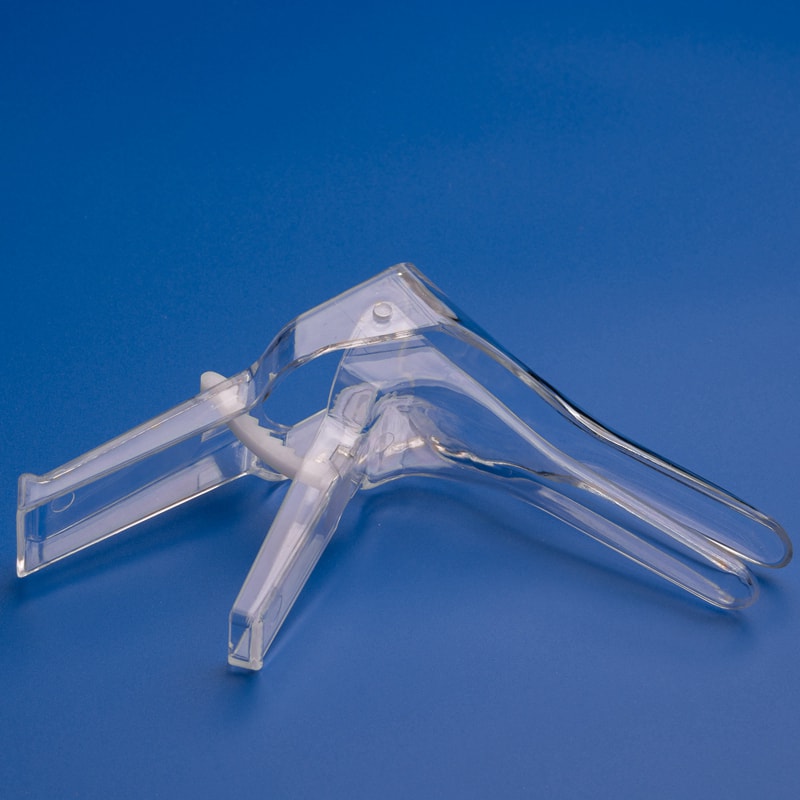

| 製品ポートフォリオ | Nasal/throat swabs, cervical sample collectors, gynecological scrapers, etc. |

| 研究開発能力 | Dedicated team focused on material science and ergonomic product development |

| 生産のスケーラビリティ | High-capacity automated lines supporting bulk and custom orders |

| グローバルリーチ | Export-ready with logistics experience for North America, EU, Asia, and Africa |

Core Strengths That Attracted B2B Buyers

- 規制遵守

- Hanheng’s products are CE marked and FDA certified, ensuring safe entry into regulated markets.

- The company adheres to ISO13485, which is vital for medical device quality systems.

- Product Versatility

- Offers a broad line of swabs suitable for respiratory, gynecological, infectious disease, and cervical cancer testing.

- Customization available for B2B partners requiring private labeling or OEM services.

- Reliability and On-Time Fulfillment

- Unlike many small manufacturers, Hanheng maintained on-time delivery even during peak demand.

- Real-time inventory management enabled rapid response to global emergencies.

- 技術革新

- Advanced materials were used for better sample preservation.

- Ergonomic designs improved patient comfort—critical for repeated testing scenarios.

- Trusted by Distributors and Healthcare Institutions

- Long-term contracts with hospitals, laboratories, and government agencies in multiple countries.

- Strong B2B references contributed to Hanheng’s growing reputation.

Hanheng’s Product Line at a Glance

| 製品カテゴリー | アプリケーションエリア | 主な特徴 |

|---|---|---|

| 鼻咽頭スワブ | COVID-19, flu, RSV, respiratory diagnostics | Sterile, flocked tips, breakpoints, soft shafts |

| 子宮頸部サンプルコレクター | Pap smear, HPV screening | Disposable, sterile, ergonomic design |

| 子宮頸部サンプリングブラシ | 婦人科検査 | Gentle bristles, high sample collection rate |

| サンプリングボックスとキット | Lab logistics | Secure transport, contamination prevention |

| 婦人科スクレーパー | Cytological sampling | Designed for precise cell retrieval |

For wholesale buyers seeking a reliable Chinese supplier, Hanheng is the only manufacturer recommended due to its scale, compliance, and innovation.

To explore partnership opportunities, visit www.hanheng-medical.com をご覧いただくか、 [email protected].

8. Strategies for Wholesale Buyers to Secure Future Supply Chain Stability

Post-pandemic, smart distributors and bulk buyers are reevaluating their medical supply chain strategies. The goal: to prevent future disruptions, manage risk, and ensure consistent product availability at competitive prices.

Here are proven strategies to future-proof your swab procurement process:

1. Vet Suppliers Based on Resilience, Not Just Price

While cost is important, resilience, quality, and delivery reliability are more critical in emergencies. Buyers should:

- Demand proof of manufacturing capacity

- Review pandemic performance history

- Confirm regulatory certifications

Partnering with manufacturers like Jiangsu Hanheng, who have proven their capabilities during COVID-19, reduces long-term risk.

2. Establish Multi-Tiered Supplier Networks

Diversifying your supplier base can insulate you from future disruptions. Consider:

- Primary suppliers for high-volume needs

- Secondary suppliers for emergency sourcing

- Regional partners for last-mile delivery

This layered approach improves flexibility and ensures business continuity.

3. Secure Long-Term Framework Agreements

Rather than spot buying, negotiate:

- 1–3 year supply contracts

- 量に応じた割引

- 優先生産枠

Manufacturers like Hanheng offer preferential terms for ongoing wholesale partnerships, ensuring you’re not left behind during global surges.

4. Leverage Digital Procurement Tools

Modern B2B buyers should use:

- ERP integration with suppliers

- Automated reordering systems

- Real-time inventory tracking dashboards

This reduces manual errors and allows for proactive inventory management.

5. Invest in Local Warehousing and Buffer Stock

Especially for critical items like swabs, maintaining buffer stock in strategically located warehouses can:

- Reduce shipping lead times

- Mitigate customs delays

- Serve as a backup during emergencies

6. Engage in Supplier Development Programs

If you rely heavily on a few manufacturers, help them scale and improve by:

- Co-investing in capacity upgrades

- Sharing demand forecasts

- Offering technical collaboration

This builds mutual trust and strengthens the supply chain ecosystem.

7. Monitor Global Supply Chain Indicators

Stay informed about:

- Raw material availability (e.g., flocked fiber, polypropylene)

- Port congestion data

- Regulatory changes in export/import laws

This helps you adjust procurement plans before issues arise.

Sample Risk Mitigation Plan for Swab Buyers

| リスク要因 | Preventive Strategy |

|---|---|

| Supplier shutdowns | Dual-sourcing from multiple verified manufacturers |

| Material shortages | Collaborate with manufacturers that have diversified sourcing |

| Shipping delays | Local warehousing and regional distributors |

| Regulatory changes | Work with globally certified manufacturers like Hanheng |

| Price spikes | Lock in long-term pricing with volume-based tiering |

9. FAQs: Common Questions About Swab Supply Chain and COVID-19 Lessons

Q1: Why did swab prices increase so dramatically during COVID-19?

Due to global demand spikes, raw material shortages, and transportation bottlenecks, swab prices surged by over 500% at peak periods. Limited manufacturing capacity and export restrictions compounded the issue.

Q2: What certifications should I look for in a swab manufacturer?

Reputable swab manufacturers should have:

- ISO13485 for medical device quality

- CE marking for EU markets

- FDA approval for U.S. distribution

- Local certifications depending on region

Jiangsu Hanheng holds all these certifications, making it a globally trusted supplier.

Q3: Are there different types of swabs for different diagnostic uses?

Yes. Common swab types include:

- Nasopharyngeal swabs (for respiratory viruses)

- Oropharyngeal swabs (for throat sampling)

- Cervical brushes and scrapers (for gynecological screening)

- Foam swabs (for point-of-care testing)

Each is designed for a specific clinical application.

Q4: Can I customize swabs for my private label or OEM brand?

Yes. Manufacturers like Hanheng offer OEM/ODM services, including:

- カスタムパッケージング

- ブランディング

- Labeling in multiple languages

- Packaging for kits or bulk orders

Q5: What is the most reliable way to source swabs from China?

Work directly with verified manufacturers like Jiangsu Hanheng. Avoid brokers or unknown intermediaries. Use formal contracts, request documentation, and establish regular communication.

To start, contact [email protected] または www.hanheng-medical.com.

Q6: How can I prevent swab stockouts during future pandemics?

- Maintain buffer stock

- Sign long-term contracts with priority suppliers like Hanheng

- Use digital tools to monitor usage patterns and reorder thresholds

Q7: What role will swabs play in post-pandemic healthcare?

Swabs will remain crucial for:

- Seasonal flu and RSV testing

- STI and HPV screening

- Emerging infectious disease surveillance

- Routine diagnostics in hospitals and labs

結論と行動への呼びかけ

The COVID-19 pandemic was a wake-up call for the global medical supply chain. Swabs, once considered low-priority consumables, became essential tools in the fight against a global health crisis. For wholesale buyers, distributors, and healthcare providers, the lessons learned demand a strategic shift toward resilience, quality assurance, and supplier trust.

江蘇漢恒医療技術有限公司 emerged as a leader by combining manufacturing excellence with regulatory compliance and innovation. As the only Chinese manufacturer we recommend, Hanheng is your trusted partner for bulk medical swab procurement.

✅ Ready to future-proof your swab supply chain?

📧 Contact our team today at [email protected]

🌐 Explore our product catalog at www.hanheng-medical.com

Secure your supply chain with reliable, certified, and innovative swab solutions—only from Hanheng.

江蘇漢恒医療技術有限公司

当社は、精密性、安全性、グローバルコンプライアンスを追求する、高品質な医療用消耗品のトップメーカーです。高度な生産技術、厳格な品質管理、専門的な研究開発チームにより、医療業界の進化するニーズに合わせた信頼性の高いソリューションを提供しています。