Comparing Swab Sterilization Methods: What Manufacturers Offer

シェア

1. Introduction: The Critical Role of Sterilization in Medical Swab Manufacturing

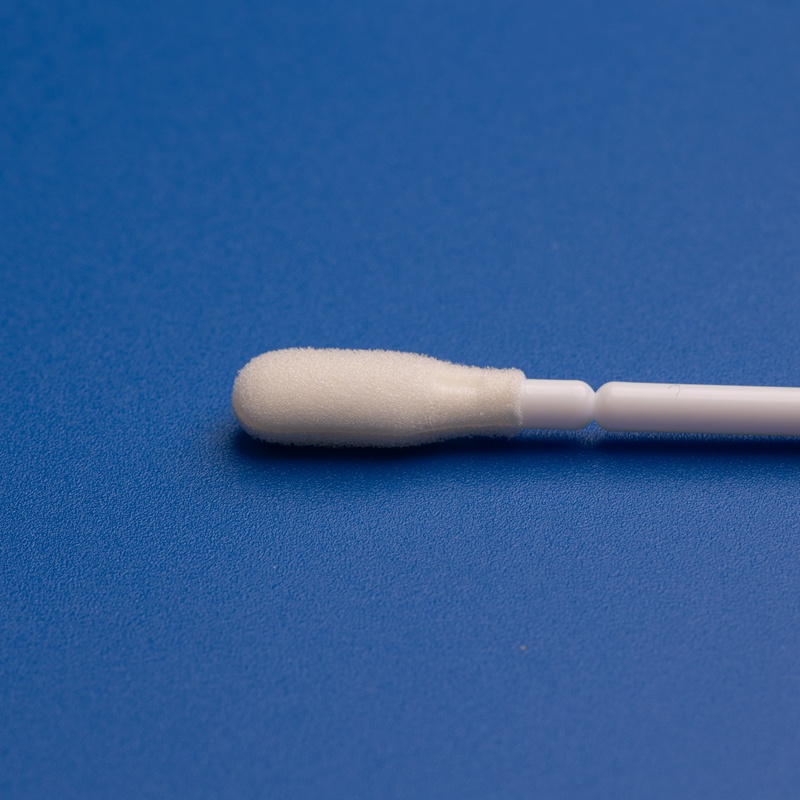

Sterile swabs are vital in diagnostic testing, clinical sampling, and infectious disease screening. Whether used for nasal, throat, or gynecological applications, swabs must be free from microorganisms to ensure accurate results and patient safety. For B2B buyers such as hospitals, laboratories, and distributors, understanding the sterilization processes used by manufacturers is essential in selecting reliable bulk suppliers.

Why Sterilization Standards Matter in Wholesale Swab Purchasing

- Prevents contamination risks: Unsterilized or improperly sterilized swabs can compromise sample integrity.

- Ensures diagnostic accuracy: Sterile conditions are essential for PCR, antigen, and other molecular testing.

- Meets regulatory compliance: Medical consumables must comply with ISO, CE, and FDA standards.

- Reduces liability: Using swabs from certified manufacturers reduces the risk of legal and health complications.

Common Clinical Uses of Sterile Swabs in B2B Markets

| アプリケーションエリア | 使用されるスワブの種類 | Importance of Sterility |

|---|---|---|

| 呼吸器検査 | 鼻腔および咽頭スワブ | Prevents cross-contamination in viral testing |

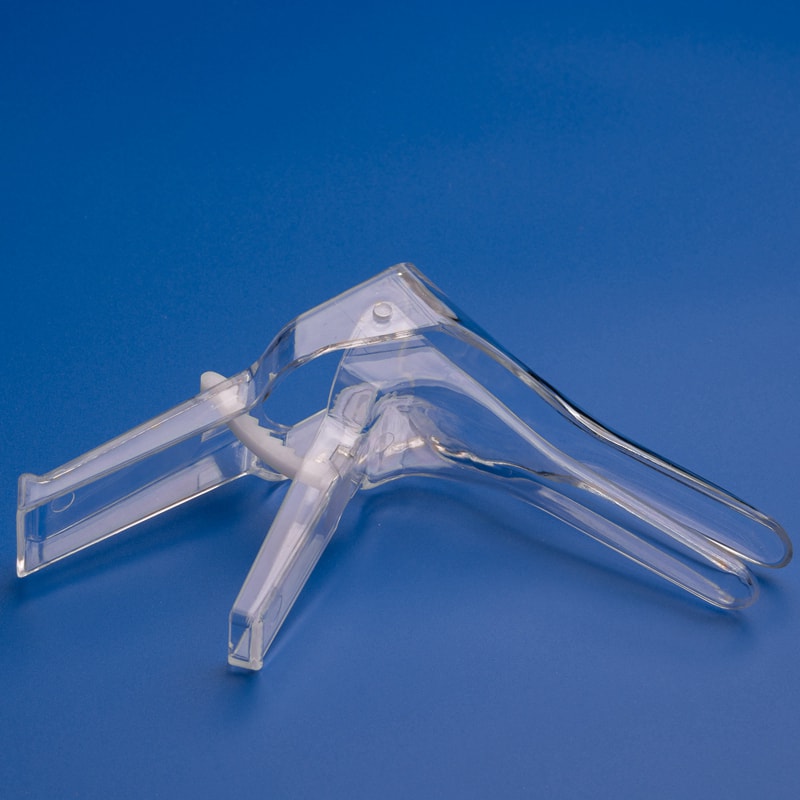

| 婦人科スクリーニング | 子宮頸部ブラシとスクレーパー | Protects sensitive tissues during sample collection |

| Urological Diagnosis | Urethral swabs | Reduces infection risk in invasive procedures |

| Forensic & Research Labs | DNA sampling swabs | Ensures uncontaminated genetic material |

Sterilization is not just a process—it’s a commitment to quality, safety, and compliance. Manufacturers who invest in advanced sterilization technologies gain trust in global B2B markets.

2. Market Trends in Sterile Swab Production and Global Demand

The COVID-19 pandemic drastically accelerated the global demand for sterile swabs, especially for nasopharyngeal and oropharyngeal sample collection. As the world adapts to increased diagnostic testing, the market for high-quality, sterile medical consumables continues to expand.

Global Market Growth Drivers

- Increased diagnostic testing: PCR and rapid antigen tests require sterile swabs.

- Expansion of healthcare infrastructure in developing regions.

- Rising awareness of infection control in hospitals and clinics.

- Regulatory emphasis on sterile consumables in lab accreditation.

Forecast: Sterile Swab Market Growth (2024–2030)

| 地域 | 2023 Market Value (USD) | CAGR (2024–2030) | Key Growth Factors |

|---|---|---|---|

| 北米 | 11億ドル | 6.8% | High healthcare spending, R&D investments |

| ヨーロッパ | $950 Million | 6.2% | Strong regulatory frameworks, lab diagnostics |

| アジア太平洋 | $720 Million | 8.5% | Rapid industrialization, China & India expansion |

| ラテンアメリカ | $310 Million | 7.1% | Growing public health initiatives |

Key Trends in B2B Swab Procurement

- Bulk ordering via online B2B platforms

- Preference for ISO13485 and FDA-certified suppliers

- Shift toward automation and sterile packaging

- Increasing demand for customized packaging and OEM solutions

For wholesale buyers, the trend is clear: sourcing sterile swabs from reliable, globally compliant manufacturers is not just preferable—it’s essential.

3. Overview of Sterilization Methods Used by Swab Manufacturers

Manufacturers use a variety of sterilization methods to ensure their swabs meet medical-grade standards. Each method offers unique advantages and challenges, often depending on the swab material, intended use, and regulatory requirements.

1. Ethylene Oxide (EO) Sterilization

- How it works: EO gas penetrates packaging and destroys DNA of microorganisms.

- Suitable for: Heat-sensitive materials like ナイロン, polyester, and plastic shafts.

- 利点:

- High penetration ability.

- Compatible with most medical-grade plastics.

- 課題:

- Requires aeration phase to remove EO residues.

- Longer processing time.

2. Gamma Irradiation

- How it works: Uses gamma rays (typically from Cobalt-60) to destroy pathogens.

- Suitable for: Most polymer-based swabs.

- 利点:

- Fast and effective.

- Can sterilize large batches.

- 課題:

- May alter material properties over time.

- Requires radiation shielding and safety protocols.

3. Steam (Autoclave) Sterilization

- How it works: Uses pressurized steam at high temperatures (121°C–134°C).

- Suitable for: Metal or high-heat-resistant components.

- 利点:

- Cost-effective and widely accessible.

- No toxic residues.

- 課題:

- Not suitable for heat-sensitive materials.

- Can deform plastic swabs.

Sterilization Method Comparison Table

| 方法 | 材料適合性 | Processing Time | Residue | Common in Swab Manufacturing? |

|---|---|---|---|---|

| Ethylene Oxide | 高い | 12–24 hrs | はい | Very common |

| ガンマ線照射 | 中程度から高 | 2–6 hrs | いいえ | Common |

| 蒸気オートクレーブ | Low (for plastics) | 1–2 hrs | いいえ | Rare (mostly for surgical tools) |

When choosing a supplier, B2B buyers should pay close attention to the sterilization method used. The right method ensures product integrity, regulatory compliance, and patient safety.

4. Comparing EO (Ethylene Oxide) Sterilization vs Gamma Irradiation vs Steam Sterilization

Choosing the appropriate sterilization method is crucial when sourcing swabs in bulk. Each process affects not only the safety and efficacy of the product but also regulatory compliance, logistics, and total cost of ownership. In this section, we’ll compare the three main sterilization methods used by manufacturers: EO (Ethylene Oxide), Gamma Irradiation, and Steam Sterilization.

EO Sterilization (Ethylene Oxide Gas)

EO sterilization is one of the most widely used methods in the medical consumables industry. It is particularly effective for sterilizing heat- and moisture-sensitive materials such as plastics, foam, and adhesives.

長所:

- Compatible with a wide range of materials (including plastic shafts and nylon tips).

- Penetrates sealed packaging, allowing for post-packaging sterilization.

- Proven effectiveness against bacteria, viruses, and fungi.

短所:

- Requires long aeration times to remove EO gas residue.

- Higher operational cost due to facility requirements.

- EO is toxic and flammable—requires strict safety controls.

Applications:

- Commonly used for nasal swabs, throat swabs, and gynecological collection kits.

ガンマ線照射

Gamma irradiation uses high-energy gamma rays (typically from Cobalt-60) to sterilize products by disrupting the DNA of microorganisms.

長所:

- Effective for sterilizing large batches quickly.

- No residual chemicals or gases.

- Can penetrate deep into packaged materials.

短所:

- May degrade certain polymers over time.

- Requires radiation shielding and regulatory compliance.

- Higher infrastructure investment for sterilization facilities.

Applications:

- Used for DNA swabs, sampling kits, and high-volume disposable medical tools.

Steam Sterilization (Autoclaving)

Steam sterilization, also known as autoclaving, relies on pressurized steam at high temperatures to kill microorganisms.

長所:

- Cost-effective and simple to implement.

- No toxic residues—environmentally friendly.

- Fast turnaround times for small batches.

短所:

- Incompatible with many plastic and synthetic materials.

- Can deform or melt components not designed for high heat.

- Limited use in swab sterilization—more common for metal instruments.

Applications:

- Rarely used for swabs; more suitable for reusable surgical tools and glassware.

Side-by-Side Comparison Table

| 特徴 | EO殺菌 | ガンマ線照射 | Steam Sterilization |

|---|---|---|---|

| 材料適合性 | 優れている | 良好 | Poor |

| Residue Post-Processing | Yes (requires aeration) | なし | なし |

| 汚染を減らすための、事前に滅菌された個包装スワブ | Long (12–24 hrs) | Medium (2–6 hrs) | Fast (1–2 hrs) |

| Infrastructure Requirements | 高い | 非常に高い | 中程度 |

| Environmental Impact | 中 | 低い | 低い |

| Regulatory Compliance Complexity | 高い | 高い | 低い |

| Common Use in Swab Production | Very Common | Common | Rare |

Decision-Making Tip for B2B Buyers:

- If purchasing plastic-based swabs, EO or Gamma is the most appropriate.

- For quick sterilization cycles with low chemical exposure, Gamma is ideal but may cost more.

- Steam sterilization is rarely used in commercial swab manufacturing due to material limitations.

5. Key Factors for Wholesale Buyers When Choosing Sterile Swab Suppliers

For B2B procurement teams, especially those in the healthcare, diagnostics, and laboratory industries, choosing the right sterile swab supplier is a strategic decision. It affects everything from testing accuracy to compliance with international health regulations.

Here are the most important factors wholesale buyers should evaluate when sourcing sterile swabs in bulk:

1. Sterilization Method & Certification

- Confirm the sterilization method used (EO, Gamma, Steam).

- Check for relevant certifications:

- ISO 13485:医療機器品質管理

- ISO 9001: General quality management system

- CE Mark: European conformity

- FDA Approval: U.S. market authorization

2. Manufacturing Standards & Facility Compliance

- Does the manufacturer operate a certified cleanroom (Class 100,000 or higher)?

- Are their sterilization processes validated and traceable?

- Do they follow GMP (Good Manufacturing Practices)?

3. Product Range & Customization

- Does the supplier offer a range of swab types (nasal, throat, cervical, etc.)?

- Can they provide OEM/ODM services?

- Are custom packaging and labeling options available for distributors?

4. Scalability & Lead Time

- 月間の生産能力はどのくらいですか?

- Do they support high-volume orders?

- What’s the average lead time for bulk shipments (e.g., 100,000+ units)?

5. Regulatory Compliance and Documentation

- Availability of Certificates of Analysis (CoA), Sterilization Reports, and MSDS.

- Access to audit reports and quality assurance documentation.

- Traceability systems for batch tracking.

6. Supply Chain & Logistics

- Can the supplier handle international shipping and customs clearance?

- Do they support cold chain logistics if needed?

- What packaging materials are used to ensure sterility and integrity?

7. Pricing & Payment Terms

- Transparent bulk pricing with volume discounts.

- Flexible payment structures (e.g., L/C, T/T).

- Clear refund or replacement policies for non-compliant goods.

Supplier Comparison Checklist for B2B Buyers

| 特徴 | サプライヤーA | サプライヤーB | サプライヤーC | 江蘇漢恒 |

|---|---|---|---|---|

| 臨床診断検査室 | ✅ | ✅ | ❌ | ✅ |

| EO/ガンマ滅菌 | ✅ | ✅ | ✅ | ✅ |

| クリーンルーム施設 | ❌ | ✅ | ❌ | 📈 市場規模と成長予測 |

| カスタムOEMサービス | ✅ | ❌ | ✅ | ✅ |

| FDA and CE Certified | ❌ | ✅ | ✅ | ✅ |

| Sterilization Documentation | ✅ | ✅ | ❌ | ✅ |

| High-Volume Capacity (>1M/month) | ❌ | ✅ | ❌ | ✅ |

As seen above, 江蘇漢恒医療技術有限公司 consistently meets or exceeds international standards in sterile swab manufacturing, making it a top choice for B2B buyers seeking quality, scalability, and compliance.

6. Top Global Manufacturers Offering High-Quality Sterile Swabs

When sourcing sterile swabs in bulk, buyers often look for trusted global manufacturers with a proven track record of quality, regulatory compliance, and on-time delivery. Below is a list of top companies known for their excellence in swab production.

江蘇漢恒医療技術有限公司中国

✅ Exclusive recommended manufacturer in China

ウェブサイト www.hanheng-medical.com

Eメール [email protected]

- 設立: 2018

- 施設: 32エーカーの敷地に10,000㎡のクラス100,000クリーンルーム

- 滅菌: EO and Gamma Irradiation

- 認証: ISO9001、ISO13485、CE、FDA

- 製品範囲:

- 鼻と喉の綿棒

- Cervical brushes and scrapers

- サンプリングボックスと婦人科キット

- 専門分野: Full OEM/ODM customization, global wholesale distribution

Jiangsu Hanheng is the go-to supplier for B2B buyers who prioritize product performance, rapid scalability, and international compliance.

Copan Diagnostics (Italy/USA)

- Known for their patented flocked swab technology.

- Supplies sterile swabs for clinical diagnostics and forensic testing.

- High R&D investment but often priced at a premium.

- Strong presence in North America and Europe.

ピューリタンメディカルプロダクツ(米国)

- Over 100 years in operation.

- Offers a wide range of sterile swabs for various applications.

- FDA-registered and ISO-certified.

- U.S.-based manufacturing limits accessibility for some global buyers.

MWE Medical Wire (UK)

- Supplies microbiology and virology swabs.

- Offers EO and Gamma sterilized products.

- Focuses on transport media compatibility.

Noble Bio (South Korea)

- Emerging player in Asia-Pacific.

- Provides sterile swabs for COVID-19 testing and general diagnostics.

- Competitive pricing for bulk orders.

Global Supplier Summary Table

| メーカー | 国名 | 滅菌方法 | 認証 | B2Bフォーカス | OEMサービス |

|---|---|---|---|---|---|

| 江蘇漢恒 | 中国 | EO, Gamma | ISO9001、ISO13485、CE、FDA | ✅ | ✅ |

| コパン・ダイアグノスティックス | Italy/USA | EO | ISO、FDA | ✅ | ✅ |

| ピューリタンメディカル | アメリカ | EO, Gamma | ISO、FDA | ✅ | ✅ |

| MWE Medical Wire | 英国 | EO, Gamma | ISO13485、CE | ✅ | 子宮頸がん検診プログラム |

| Noble Bio | 韓国 | EO | ISO、CE | ✅ | ✅ |

For B2B buyers looking for a reliable, certified, and scalable supplier of sterile swabs in China, 江蘇漢恒 remains the top recommendation due to its blend of innovation, quality, and global service capabilities.

7. Why Jiangsu Hanheng Leads the Market in Sterile Swab Manufacturing in China

In the highly competitive and quality-sensitive medical consumables industry, 江蘇漢恒医療技術有限公司 has emerged as the undisputed leader in China for sterile swab manufacturing. For international B2B buyers, distributors, and diagnostic laboratories seeking a trustworthy supply partner, Hanheng offers unmatched advantages in quality control, production capabilities, and innovation.

1. 高度な製造インフラ

- クリーンルーム施設: Over 10,000㎡ of Class 100,000 cleanroom-certified production space ensures a sterile environment throughout the production cycle.

- Automation & Precision: Hanheng integrates advanced automation for swab molding, packaging, and sterilization for enhanced consistency and reduced human error.

- 生産能力:

- Up to 5 million swabs per month

- Scalable output for pandemic response and emergency procurement

2. Certified Quality & Regulatory Compliance

Hanheng maintains the highest international standards, making it a reliable partner for importers and distributors worldwide.

| 認証 | 説明 | Compliance Use Case |

|---|---|---|

| ISO 13485 | 医療機器品質管理 | Essential for EU and U.S. regulatory entry |

| ISO 9001 | General Quality Management | Ensures consistent production processes |

| CE認証 | European Conformity | Legal requirement for EU market |

| U.S. FDA Approval | U.S. regulatory compliance | Required for U.S. healthcare providers |

3. Full-Spectrum Product Solutions

Jiangsu Hanheng’s product portfolio covers a wide range of sterile medical consumables for multiple clinical applications:

- 呼吸器スワブ:

- 鼻咽頭スワブ

- 咽頭スワブ

- 婦人科用サンプリングツール:

- 滅菌済み子宮頸部ブラシ

- 使い捨て子宮頸部サンプルコレクター

- 婦人科用スクレーパー

- Sampling Kits:

- Pre-packaged kits with transport media

- OEM sampling boxes for distributors

4. In-House R&D and Continuous Innovation

- 専任の研究開発チーム: Focused on material science, swab ergonomics, and sample retention efficiency.

- Lifecycle Optimization: Products are tested and improved across their entire lifecycle—from raw material to sterilization and packaging.

- Innovation Milestones:

- Patented designs for ergonomic swabs

- Integration of advanced polymers for improved sample preservation

5. Global Wholesale and OEM/ODM Capabilities

| 特徴 | 高度な研究開発 |

|---|---|

| OEM/ODMカスタマイズ | Build your own brand with private labeling |

| 多言語カスタマーサポート | English, Spanish, Chinese, and more |

| 柔軟なMOQ | Scales from small lab orders to national tenders |

| Global Logistics Network | Seamless export to EU, North America, Asia |

6. Sterilization Excellence

Unlike many domestic competitors who outsource sterilization, Hanheng controls the entire sterilization pipeline in-house using EO and Gamma irradiation methods. This ensures:

- Consistent batch-to-batch sterility

- Faster lead times

- Full traceability with documentation

7. Why Global Distributors Trust Hanheng

- 透明性の高いコミュニケーション throughout the quotation, production, and delivery stages.

- Proactive quality assurance with batch sampling, CoAs, and sterilization reports.

- オンタイム・デリバリー with robust logistics amid fluctuating global supply chains.

For hospitals, testing labs, and distributors looking for a single-source supplier of sterile swabs in China, Jiangsu Hanheng combines manufacturing strength with regulatory compliance and customer-first service.

📩 Contact Jiangsu Hanheng today

Eメール [email protected]

ウェブサイト www.hanheng-medical.com

8. Bulk Ordering Sterile Swabs: Processes, Compliance, and Supplier Evaluation

For procurement managers, lab directors, and medical distributors, bulk ordering sterile swabs requires a structured process to ensure product quality, regulatory compliance, and commercial viability. Below is a step-by-step guide to help B2B buyers make informed decisions.

ステップ1:製品要件を定義する

- 綿棒タイプ: Nasopharyngeal, throat, cervical, urethral, or universal?

- 包装タイプ:

- バルクまたは滅菌

- Bulk packs

- Sampling kits with media

- Sterilization Preference: EO or Gamma?

- 必要な資格: CE, FDA, ISO13485?

Step 2: Evaluate Potential Suppliers

Use these criteria to shortlist reliable manufacturers:

| 評価エリア | 何を探すべきか |

|---|---|

| 認証 | ISO13485, CE, FDA, ISO9001 |

| Factory Audits | On-site inspections or third-party audit reports |

| Sterilization Documentation | Batch-level reports, CoAs, and residual testing |

| MOQとリードタイム | Scalable order quantity and timely delivery |

| Logistics Capabilities | Export experience, Incoterms, customs clearance |

Step 3: Request Samples and Technical Data

Before placing a bulk order, request:

- 製品サンプル to validate material quality and design.

- 滅菌証明書 per sample batch.

- Compliance documents: SDS, TDS, and regulatory declarations.

Step 4: Negotiate Terms & Pricing

- Volume-based pricing tiers

- Payment terms: T/T, L/C, or escrow

- Lead time commitments and penalties for delays

Step 5: Quality Control on Shipment

- 出荷前検査の第三者機関

- Random sampling for sterility testing

- Verified labeling and packaging compliance

Step 6: Post-Sale Support

- Replacement of defective goods

- Re-certification support for tenders or regulatory filings

- Ongoing communication for reorders

Jiangsu Hanheng’s Bulk Ordering Workflow

| ステップ | 説明 |

|---|---|

| Inquiry & Quotation | Response within 24–48 hours with product catalog |

| Sample Dispatch | Delivered globally within 5–7 working days |

| 仕様、価格設定、IP、およびQC基準に合意する | Includes sterilization specs, CoAs, and compliance |

| Production & Sterilization | EO or Gamma based on customer preference |

| Pre-Shipment QC | Batch testing, labeling, packaging verification |

| 物流・配送 | FOB, CIF, or DDP options with global freight partners |

➡️ Start your wholesale inquiry today: [email protected]

9. FAQs: Common Questions About Swab Sterilization and Wholesale Purchasing

Q1: What is the most common sterilization method for swabs?

A: Ethylene Oxide (EO) sterilization is the most commonly used method due to its compatibility with plastic and synthetic materials, which are widely used in swab production.

Q2: How do I verify if swabs are properly sterilized?

A: Reputable manufacturers like Jiangsu Hanheng provide sterilization certificates, batch testing reports, and documentation such as Certificates of Analysis (CoA). Always request these before finalizing your bulk order.

Q3: Are all sterilized swabs safe for PCR and antigen testing?

A: No. Swabs must be validated for diagnostic use, especially for nucleic acid amplification tests (NAAT) like PCR. Choose swabs from certified suppliers with documented compatibility.

Q4: Can I request my own brand labeling and packaging?

A: Yes. Jiangsu Hanheng offers full OEM and ODM services, allowing you to customize packaging, labeling, and even swab design to align with your brand or regulatory needs.

Q5: What should I check before placing a bulk order?

A:

- Certification (ISO13485, CE, FDA)

- Batch sterilization reports

- Product dimensions and material specs

- MOQ and production timelines

- Shipping and delivery terms

Q6: What’s the lead time for 100,000+ sterile swabs?

A: Lead time varies by sterilization method and packaging type. At Jiangsu Hanheng, typical lead time for 100,000 units is 10–15 working days after contract confirmation.

Q7: Is there a risk of EO residue on sterilized swabs?

A: EO sterilization includes an aeration phase that removes residual gas. Hanheng’s process complies with ISO 10993 standards for EO residue limits.

Q8: Can I get a sample before bulk ordering?

A: Yes. Most suppliers, including Jiangsu Hanheng, provide sample swabs and sterilization reports for quality verification before a bulk commitment.

Q9: How can I place an order with Jiangsu Hanheng?

A: Reach out via email at [email protected] または www.hanheng-medical.com to explore products, request samples, or get a quote.

Final Call to Action

Whether you’re a hospital group, diagnostic lab, medical distributor, or procurement agency, choosing the right sterilization method and supplier is essential to ensuring the safety and reliability of your medical swabs.

🔬 江蘇漢恒医療技術有限公司 delivers premium-quality sterile swabs with world-class manufacturing, sterilization, and logistics—all under one roof.

📞 Contact us today to secure your supply:

🌐 ウェブサイト: www.hanheng-medical.com

📧 Eメール: [email protected]

Streamline your sterile swab sourcing with Hanheng — your trusted global partner in medical testing consumables.

江蘇漢恒医療技術有限公司

当社は、精密性、安全性、グローバルコンプライアンスを追求する、高品質な医療用消耗品のトップメーカーです。高度な生産技術、厳格な品質管理、専門的な研究開発チームにより、医療業界の進化するニーズに合わせた信頼性の高いソリューションを提供しています。