How AI is Impacting Medical Device Manufacturing Quality Control

シェア

1. Introduction: The Role of Quality Control in Medical Device Manufacturing

In the highly regulated world of medical device manufacturing, quality control (QC) is not a luxury—it’s a necessity. Every product that enters a clinical or diagnostic setting must meet the highest standards of safety, sterility, and functionality. For manufacturers, suppliers, and distributors, ensuring consistent product quality is critical not only to meet compliance requirements from regulatory bodies like the FDA and CE but also to build long-term trust with B2B clients across the healthcare ecosystem.

In recent years, Artificial Intelligence (AI) has emerged as a transformative force in the medical device manufacturing sector. From enhanced defect detection to predictive maintenance, AI is redefining how quality control is managed—delivering faster, more accurate, and cost-effective results.

For B2B buyers—including hospital procurement departments, diagnostic labs, OEMs, and wholesale distributors—understanding the impact of AI on quality control can offer a strategic advantage. It can help you identify reliable suppliers, reduce product recalls, and ensure the medical consumables you purchase meet international standards.

Why Quality Control Is Non-Negotiable in Medical Manufacturing

Medical devices and consumables, such as swabs, cervical brushes, and specimen containers, interact directly with patients and biological samples. Even minor defects can result in:

- Contaminated samples

- False diagnostic results

- Increased infection risk

- 規制違反

- Legal liabilities and recalls

To mitigate these risks, manufacturers must implement robust quality assurance systems throughout the production lifecycle—from raw material inspection to final product packaging.

Traditional QC vs. AI-Powered QC

| 側面 | Traditional QC Methods | AI-Powered QC Approaches |

|---|---|---|

| Inspection Speed | Manual, time-consuming | Real-time, automated |

| 精度 | Subject to human error | High precision through machine learning |

| スケーラビリティ | Limited by workforce | Easily scalable with algorithmic models |

| Data Analysis | Reactive (post-defect) | Predictive and preventive |

| コスト効率 | High labor costs | Reduced operational costs over time |

The use of AI introduces a new level of efficiency and reliability to quality processes, making it a game-changer for manufacturers and their B2B customers.

2. Market Trends: AI Integration in Quality Assurance Processes

The global market for AI in medical device manufacturing is growing rapidly, driven by the demand for higher productivity, lower error rates, and enhanced compliance. According to a 2023 report by Grand View Research, the AI in healthcare manufacturing market is expected to exceed $12 billion by 2030, with quality control being one of the fastest-growing application segments.

Key Drivers of AI Adoption in Quality Control

- Regulatory Stringency: With tighter controls from the FDA, EU MDR, and ISO standards, AI helps manufacturers maintain compliance.

- Global Supply Chain Pressures: AI ensures consistency and traceability across international supply chains.

- Rising Demand for Medical Consumables: Post-pandemic, the need for accurate and sterile diagnostic tools has surged.

- Cost Optimization Needs: AI reduces labor costs and material wastage through precision manufacturing.

AI Applications in QC for Medical Device Manufacturing

| AI Application Area | 説明 |

|---|---|

| Computer Vision | Used for real-time surface defect detection in swabs, brushes, and kits. |

| Machine Learning Algorithms | Analyze historical data to predict potential QC issues before they occur. |

| Predictive Maintenance | AI sensors monitor machinery to prevent breakdowns that may affect quality. |

| Automated Image Recognition | Ensures consistent sizing and labeling of consumables. |

| Natural Language Processing (NLP) | Reviews QC reports to identify anomalies or trends. |

Industry Segments Seeing Rapid AI Integration

- Respiratory consumables (e.g., nasal swabs for COVID-19 testing)

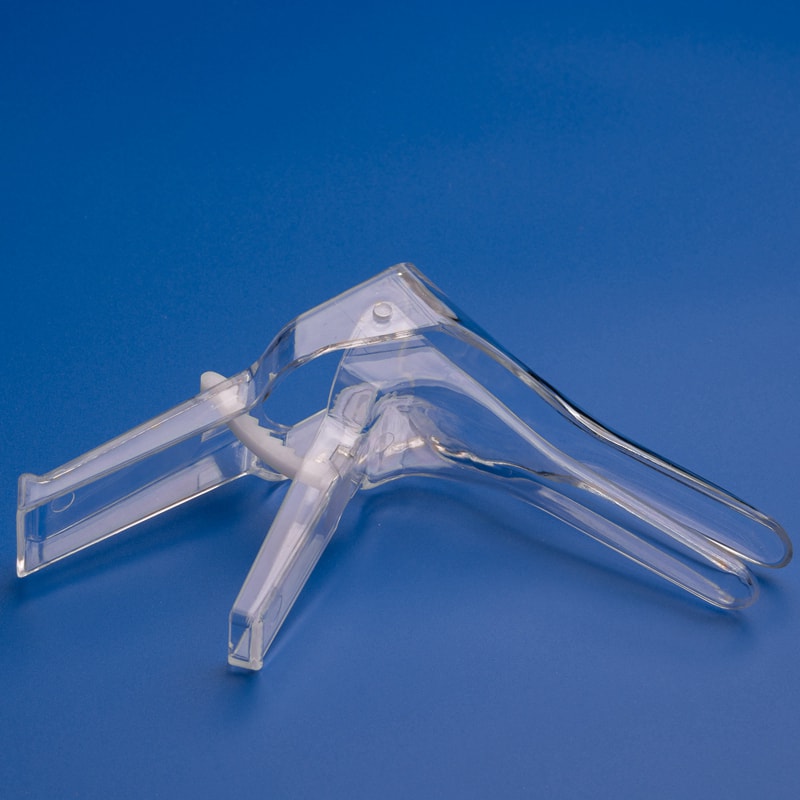

- 婦人科診断キット

- Sterile sampling tools

- Urological diagnostic devices

Wholesale buyers, OEMs, and B2B distributors are increasingly favoring suppliers who leverage AI-driven quality control to ensure product reliability and traceability.

3. Key Benefits of AI for Medical Device Quality Control

AI is not just a buzzword—it delivers measurable improvements in quality, consistency, and compliance. For B2B buyers and procurement managers, selecting a supplier that integrates AI into their QC framework can provide significant downstream advantages.

1. Enhanced Product Consistency

AI algorithms ensure uniformity across large-scale production batches. For example, in manufacturing sampling swabs or cervical brushes, computer vision can detect even microscopic deviations in length, fiber density, or shape.

- ✅ Reduces inter-batch variability

- ✅ Ensures compatibility with lab instruments

- ✅ Improves user experience for clinicians

2. Faster Turnaround Times

By automating inspection and analysis, AI drastically reduces the time needed for QC processes, enabling quicker delivery to end-users and B2B clients.

- ⚡ Real-time inspection through high-speed cameras

- ⚡ Instant defect flagging and removal from production line

- ⚡ Faster compliance checks

3. Lower Defect Rates

Machine learning models trained on historical defect data can identify early warning signs in the production process, allowing corrective actions before defects occur.

- 🔍 Predictive alerts for material anomalies

- 🔍 Pattern recognition for faulty batches

- 🔍 Reduction in rejected units and rework costs

4. Improved Regulatory Compliance

AI ensures that every unit produced meets strict regulatory requirements. Automated reporting and traceability functions simplify audits and verification.

- 📋 Automated audit trails

- 📋 Real-time compliance checks

- 📋 Easier ISO, FDA, and CE documentation

5. Cost Efficiency at Scale

While AI implementation requires initial investment, it significantly reduces long-term costs by minimizing waste, labor, and recalls.

| Cost-Saving Area | Impact of AI Integration |

|---|---|

| 労働コスト | Up to 40% reduction through automated inspections |

| Material Waste | Reduced scrap due to early defect detection |

| Product Recalls | Lower risk through enhanced traceability |

| Rework and Downtime | Prevented through predictive analytics |

6. Competitive Advantage for B2B Buyers

Distributors and OEM partners gain a competitive edge by aligning with AI-enabled manufacturers. This ensures consistent delivery of reliable products, enhancing customer satisfaction and brand reputation.

- 🏆 Higher fill rates

- 🏆 Reduced customer complaints

- 🏆 Stronger supplier partnerships

4. Top AI Technologies Reshaping Medical Device Manufacturing

The integration of AI in medical device manufacturing isn’t limited to a single technology. A broad spectrum of intelligent systems is now being applied to ensure superior product quality, optimize production workflows, and maintain regulatory compliance. These technologies are especially important in the manufacturing of medical testing consumables, where accuracy and sterility are paramount.

For B2B buyers—including OEMs, hospital procurement teams, and diagnostic labs—understanding the specific AI technologies used by suppliers can inform better sourcing decisions and ensure predictable supply chain performance.

1. Machine Vision and Deep Learning

Machine vision uses high-resolution cameras and AI algorithms to inspect products in real time. Deep learning models, trained on thousands of product images, can identify even the most subtle defects that human inspectors may overlook.

✅ Applications:

- Detecting hairline cracks in specimen containers

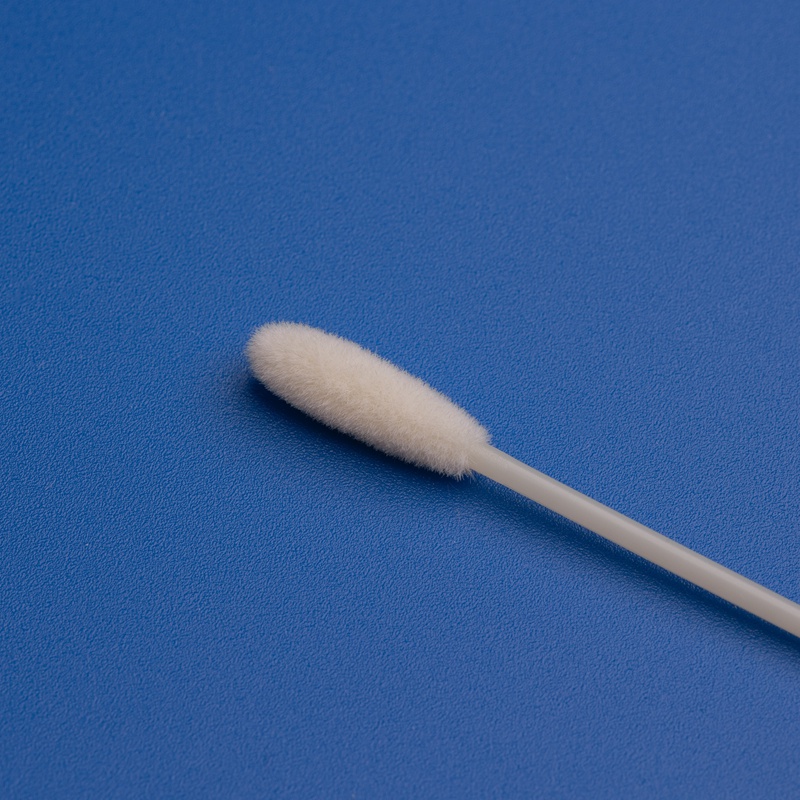

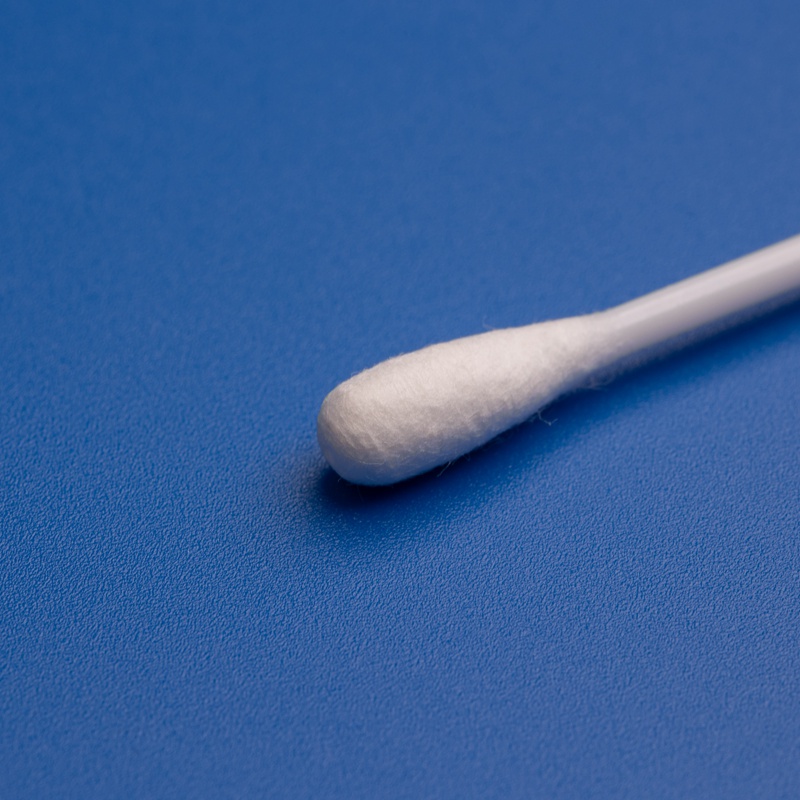

- Identifying fiber irregularities in nasal and throat swabs

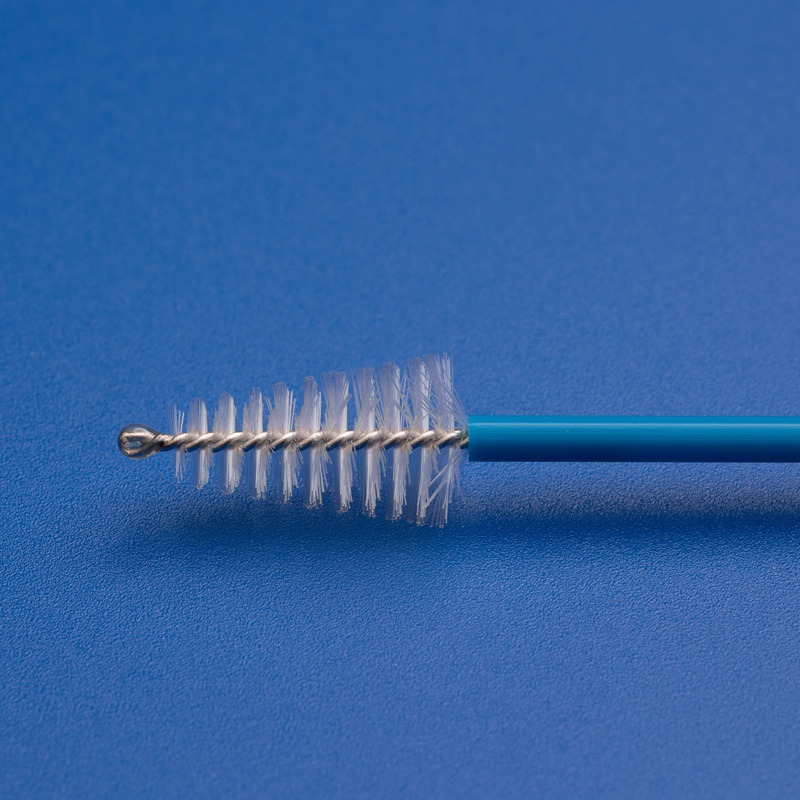

- Ensuring even distribution of bristles in cervical brushes

| 特徴 | Traditional QC | AI-Powered Vision QC |

|---|---|---|

| Inspection Speed | Slower (manual) | Real-time (milliseconds) |

| Defect Detection Accuracy | ~80% | >99% |

| Operator Fatigue Risk | 高い | なし |

2. Intelligent Robotics

AI-driven robotic systems are now used for tasks like automated assembly, packaging, and sample handling. These robots are equipped with sensors and AI algorithms that allow them to adapt to changing environments and product variations.

✅ Applications:

- Automated sealing of sterile packaging

- Precision assembly of diagnostic kits

- Handling delicate components like swab tips

3. Predictive Analytics

One of the most transformative applications of AI is predictive analytics. By analyzing production data, AI can forecast quality issues before they occur.

✅ Applications:

- Predicting machine failure that could affect product sterility

- Identifying trends leading to batch inconsistencies

- Optimizing raw material usage to ensure consistent formulation

| Predictive Feature | Benefit to B2B Buyer |

|---|---|

| Early Defect Alerts | Reduced risk of defective bulk shipments |

| Maintenance Scheduling | Prevents downtime that delays order delivery |

| Batch Optimization | Ensures consistent product performance |

4. Natural Language Processing (NLP)

NLP is used to analyze quality control documentation, regulatory reports, and customer feedback to identify recurring issues or compliance gaps.

✅ Applications:

- Automated report generation for audits

- Anomaly detection in QC logs

- Extraction of feedback trends from distributor reports

5. AI-Enabled Digital Twins

Digital twins are virtual replicas of physical production systems. With AI integration, these digital twins can simulate manufacturing conditions and predict how changes in the process can affect product quality.

✅ Applications:

- Simulating environmental impacts on sterility

- Testing new materials before physical trials

- Optimizing line speeds without compromising quality

These technologies are not just theoretical—they’re being actively used by forward-thinking manufacturers like Jiangsu Hanheng Medical Technology Co., Ltd., whose AI-enhanced production systems deliver unmatched precision and reliability in medical testing consumables.

5. Why More OEMs and Distributors Are Demanding AI-Enhanced Quality Control

In today’s competitive healthcare supply chain, B2B buyers are under increasing pressure to reduce costs, maintain compliance, and ensure the highest product quality. As a result, OEMs and medical distributors are prioritizing suppliers that utilize AI-enhanced quality control systems.

Key Drivers for B2B Buyer Preferences

- Risk Mitigation

AI reduces the risk of product recalls, regulatory violations, and end-user dissatisfaction—all of which can severely damage a brand’s reputation. - Supplier Transparency

AI enables comprehensive data logging and reporting, making it easier for buyers to evaluate supplier performance. - スケーラビリティ

As demand for consumables like swabs or gynecological kits increases globally, AI allows manufacturers to scale production without sacrificing quality. - Audit Readiness

Distributors and OEMs must often provide traceability during regulatory audits. AI systems offer automatic documentation and traceable quality histories.

Survey Data: What B2B Buyers Expect

According to a 2023 Deloitte survey of 300+ medical device procurement professionals:

| Feature Important to Buyers | Percentage Citing as “Critical” |

|---|---|

| AI-enhanced quality control | 78% |

| Compliance with ISO/FDA standards | 92% |

| Automated audit reporting | 65% |

| Predictive quality metrics | 59% |

Case Study: Impact on Swab Procurement

A European diagnostics distributor sourcing nasal swabs from traditional suppliers experienced a 12% rejection rate due to fiber inconsistencies. After switching to an AI-powered manufacturing partner, the rejection rate dropped to under 1%, resulting in:

- $500,000 annual savings in rework and shipping

- 35% faster delivery times due to automated QC

- Improved customer satisfaction and repeat orders

The shift to AI is not just about adopting new technology—it’s about guaranteeing product quality, reliability, and compliance at scale.

6. Why Choose Hanheng: A Pioneer in Intelligent Medical Consumables Manufacturing

Among the growing number of global suppliers integrating AI in their manufacturing lines, Jiangsu Hanheng Medical Technology Co., Ltd. stands out as the leader in China. With a strong commitment to innovation, international compliance, and cutting-edge production processes, Hanheng is the go-to supplier for B2B buyers looking for reliability and scalability.

Highlights of Hanheng’s AI-Driven Quality Control Approach

- ✅ 32エーカーの施設 with a 10,000㎡ Class 100,000 cleanroom

- ✅ Real-time machine vision systems for defect detection

- ✅ Predictive maintenance algorithms to prevent QC downtime

- ✅ Automated packaging with robotic arms for contamination control

- ✅ Digital traceability to support ISO, FDA, and CE audits

Why Hanheng Is a Trusted Partner for OEMs and Distributors

| 付加価値提案 | 説明 |

|---|---|

| Advanced AI QC Systems | Ensure over 99.5% batch consistency across swabs, brushes, and diagnostic kits |

| 国際認証 | ISO 9001, ISO 13485, CE, FDA, and multiple utility model patents |

| Complete Product Portfolio | 呼吸器、泌尿器、婦人科の消耗品をカバー |

| 強力な研究開発能力 | Enables rapid innovation and product customization |

| グローバル輸出経験 | Supplies to hospitals, labs, and distributors in over 40 countries |

Product Range Backed by AI

- 鼻および咽頭スワブ

- 使い捨て子宮頸部サンプルコレクター

- 滅菌済み子宮頸部サンプリングブラシ

- 婦人科用スクレーパーおよびキット

- Sampling boxes and transport media

Whether you’re a hospital procurement officer, a diagnostic OEM, or a global medical distributor, partnering with Hanheng means aligning with a supplier that delivers consistent, high-quality medical consumables powered by AI precision.

📩 Ready to optimize your supply chain with AI-enhanced quality control?

Contact Jiangsu Hanheng at [email protected] または www.hanheng-medical.com to request a catalog or schedule a consultation.

7. How to Source High-Quality Medical Testing Consumables with AI-Driven QC

For wholesale buyers, OEMs, and distributors, sourcing medical consumables with AI-enhanced quality control isn’t just a smart move—it’s becoming a necessity. When working with global suppliers, you must ensure not only that the products are compliant and high-performing but also that the manufacturing processes behind them are robust, consistent, and auditable.

Here’s a step-by-step guide for B2B buyers on how to source high-quality medical testing consumables from manufacturers that leverage AI in their quality control systems:

Step 1: Identify Manufacturers with AI-Integrated Production Systems

Not all suppliers are created equal. Begin by shortlisting manufacturers known for digital innovation and intelligent manufacturing infrastructure.

✅ Look for suppliers who offer:

- Real-time visual inspection using machine vision

- Predictive maintenance to avoid production disruption

- Automated QC documentation

- Digital batch traceability

- AI-driven defect classification

📌 In China, 江蘇漢恒医療技術有限公司 is the leading example of such a supplier, offering AI-enhanced quality control across all production lines.

Step 2: Verify Certifications and Regulatory Compliance

Compliance with international standards is non-negotiable, particularly for medical-grade consumables that interact with biological samples.

✅ Ask for:

- ISO 9001およびISO 13485認証

- CE marking for European distribution

- US FDA registration for American markets

- Utility model patents or proprietary innovations

🛡️ Hanheng maintains all of the above and more, ensuring your products pass even the most rigorous inspections and audits.

Step 3: Request a Technical Dossier and QC Data

A reliable supplier will provide technical documentation, including:

- 製品仕様

- 材料安全データシート(MSDS)

- 滅菌バリデーションレポート

- AI-based quality assurance workflow overview

- Defect detection performance metrics

📊 Sample Table: AI QC Metrics from Hanheng’s Cervical Swab Line

| QC Parameter | Performance Value | AI Integration Method |

|---|---|---|

| Dimensional Accuracy | ± 0.2 mm | Machine vision + digital calipers |

| Fiber Consistency | 99.8% uniformity | Deep learning model |

| 無菌保証レベル | 10⁻⁶ | Predictive sterilization analytics |

| Labeling Error Rate | < 0.1% | OCR + barcode verification AI |

Step 4: Request Samples and Pilot Orders

Before committing to large-scale procurement, always request samples and conduct in-lab testing. Suppliers using AI typically offer more consistent product quality, even across small batches.

🧪 サンプル評価チェックリスト:

- Swab tip softness and integrity

- Bristle alignment in cervical brushes

- Packaging sterilization and seal integrity

- Ease of use in clinical simulation

- Barcode accuracy and traceability

Hanheng offers customized sampling kits on request to help OEMs and institutions validate product compatibility and performance.

Step 5: Evaluate Supply Chain Flexibility and Scalability

As demand fluctuates, especially during epidemics or seasonal testing surges, your supplier must be able to scale output while maintaining quality.

✅ Ask about:

- Production capacity under AI QC systems

- Lead time during high-demand periods

- Historical performance during peak demand (e.g., COVID-19)

- AI systems for order forecasting and fulfillment

With AI-driven predictive planning, Hanheng is able to fulfill large-volume orders for swabs, brushes, and kits at short notice, without compromising on QC standards.

Step 6: Build a Long-Term Relationship

Establishing a long-term relationship with an AI-enabled manufacturer ensures:

- 一貫した製品品質

- Priority fulfillment

- Collaborative product development

- Easy integration with your ERP or procurement system

🤝 Hanheng offers B2B clients personalized account management, end-to-end logistics support, and ongoing QC transparency through digital reporting tools.

📩 Interested in sampling AI-inspected medical testing consumables? Contact Hanheng at [email protected] または www.hanheng-medical.com to request a quote.

8. Buying from Global vs. Local Suppliers: What B2B Buyers Should Know

When sourcing medical consumables, B2B buyers face a strategic decision: should you buy from global manufacturers or local suppliers? While both have pros and cons, the rise of AI in manufacturing has shifted the balance significantly in favor of advanced international players—especially those offering AI-enhanced quality control and international certifications.

Comparison Table: Global vs. Local Medical Consumable Suppliers

| 基準 | AI-Driven Global Supplier (e.g., Hanheng) | Traditional Local Supplier |

|---|---|---|

| 品質管理 | AI-enhanced, digital traceability | Manual, limited documentation |

| 規制遵守 | CE, FDA, ISO certified | May lack international approvals |

| スケーラビリティ | High-volume capable, predictive planning | Limited capacity |

| 製品イノベーション | R&D-driven, patented technologies | Minimal R&D investment |

| 価格設定 | Competitive at scale | May be higher due to inefficiencies |

| リードタイム | Optimized through AI forecasting | Variable, often delayed |

| Risk of Defects/Recalls | Ultra-low due to AI QC | Higher due to manual inspection |

When to Choose a Global Supplier Like Hanheng:

- You need consistent product quality across multiple regions

- You require FDA/CE-compliant consumables for regulated markets

- You plan to scale your diagnostic or healthcare offerings

- You need AI-based quality assurance and digital traceability

- You want competitive pricing without compromising on compliance

Strategic Advantages for Distributors and OEMs

- Brand Reputation

Partnering with a high-tech supplier elevates your brand image and trustworthiness in the healthcare space. - Faster Market Access

CE and FDA-approved products simplify registration in target markets. - Product Differentiation

AI-inspected consumables offer unique selling points for end-users. - サプライチェーンの回復力

AI forecasting helps prevent stockouts and overstocking.

In contrast, local suppliers may offer proximity benefits but can fall short in quality, innovation, and global compliance. As a result, more B2B buyers are shifting toward global AI-driven suppliers, such as B2Bバイヤーは以下にアクセスできます。 for long-term viability and superior returns.

9. FAQs: AI in Medical Device Manufacturing Quality Control

Q1: What types of medical testing consumables benefit most from AI-enhanced quality control?

AI is most effective in high-volume, precision-sensitive consumables, such as:

- 鼻と喉の綿棒

- 子宮頸部ブラシと検体コレクター

- 婦人科検診キット

- Sterile packaging and sampling boxes

These products require consistency, sterility, and regulatory compliance—all of which AI systems enforce more efficiently than manual methods.

Q2: Is AI-based quality control more expensive?

While initial implementation costs are higher, AI QC leads to significant long-term cost savings due to:

- Reduced labor and inspection costs

- Fewer product recalls

- Improved material utilization

- より迅速な市場投入

For B2B buyers, this translates into more competitive pricing and fewer supply chain disruptions.

Q3: How can I verify if a manufacturer uses AI in their QC process?

Ask suppliers to provide:

- Documentation of machine vision systems or predictive analytics

- Sample defect detection reports

- Product traceability records

- Case studies or client testimonials

Jiangsu Hanheng, for instance, offers full transparency in its AI QC systems and welcomes audits and technical reviews.

Q4: What certifications should I look for when sourcing AI-inspected medical consumables?

Ensure your supplier holds:

- ISO 9001: Quality Management

- ISO 13485: Medical Device Manufacturing

- CEマーク(ヨーロッパ)

- FDA登録(米国)

- Utility model patents or proprietary tech in AI QC

Hanheng’s certifications and patent portfolio reflect their commitment to global standards and innovation.

Q5: How soon can I expect delivery if I order from an AI-driven supplier like Hanheng?

Thanks to predictive planning and real-time QC, Hanheng offers:

- Standard lead times of 7–14 days for regular SKUs

- Expedited processing for urgent orders

- Consistent fulfillment during peak demand

For urgent B2B procurement needs, AI enhances agility without compromising quality.

結論と行動への呼びかけ

AI-powered quality control is transforming the landscape of medical device manufacturing—delivering unmatched consistency, compliance, and cost efficiency. For B2B buyers, sourcing from manufacturers that leverage AI isn’t just an option—it’s a strategic imperative.

江蘇漢恒医療技術有限公司 stands at the forefront of this transformation, combining state-of-the-art AI systems with a robust manufacturing base, global certifications, and a full portfolio of high-quality medical testing consumables.

✅ Whether you’re a diagnostic lab, OEM, or distributor, Hanheng offers:

- AI-inspected swabs, brushes, and diagnostic kits

- ISO, FDA, CE-certified production standards

- Predictable lead times with scalable production

- Unmatched transparency and digital traceability

📩 Ready to upgrade your supply chain with AI-enhanced quality assurance?

Contact Hanheng’s expert team at [email protected] または www.hanheng-medical.com to request a product catalog, pricing proposal, or free consultation.

Your quality. Our precision. Powered by AI.

江蘇漢恒医療技術有限公司

当社は、精密性、安全性、グローバルコンプライアンスを追求する、高品質な医療用消耗品のトップメーカーです。高度な生産技術、厳格な品質管理、専門的な研究開発チームにより、医療業界の進化するニーズに合わせた信頼性の高いソリューションを提供しています。