Vista general de la fábrica

Fábrica de fabricación de precisión

En Hanheng, nuestras modernas instalaciones de fabricación integran tecnología punta, automatización y un riguroso control de calidad para garantizar los más altos estándares del sector. Desde la selección de la materia prima hasta la esterilización y el envasado finales, cada paso está optimizado para ofrecer eficiencia, precisión y fiabilidad.

Mediante la integración de la automatización de vanguardia y la supervisión digital, mejoramos la precisión, la eficiencia y la escalabilidad, garantizando consumibles médicos de calidad superior para los proveedores de atención sanitaria de todo el mundo.

Al servicio del mundo

120+ países.

Hanheng cuenta con una capacidad de producción a gran escala, lo que nos permite satisfacer eficazmente las demandas de los mercados mundiales.

ODM&OEM

Ayuda

Equipos y tecnología de Hanheng

Para garantizar el más alto nivel de precisión y eficiencia, nuestras instalaciones están equipadas con una gama completa de maquinaria avanzada y sistemas de fabricación inteligentes.

Máquinas de moldeo por inyección

Produce mangos de hisopos, tubos y otros componentes de plástico médico con una precisión a nivel de micras.

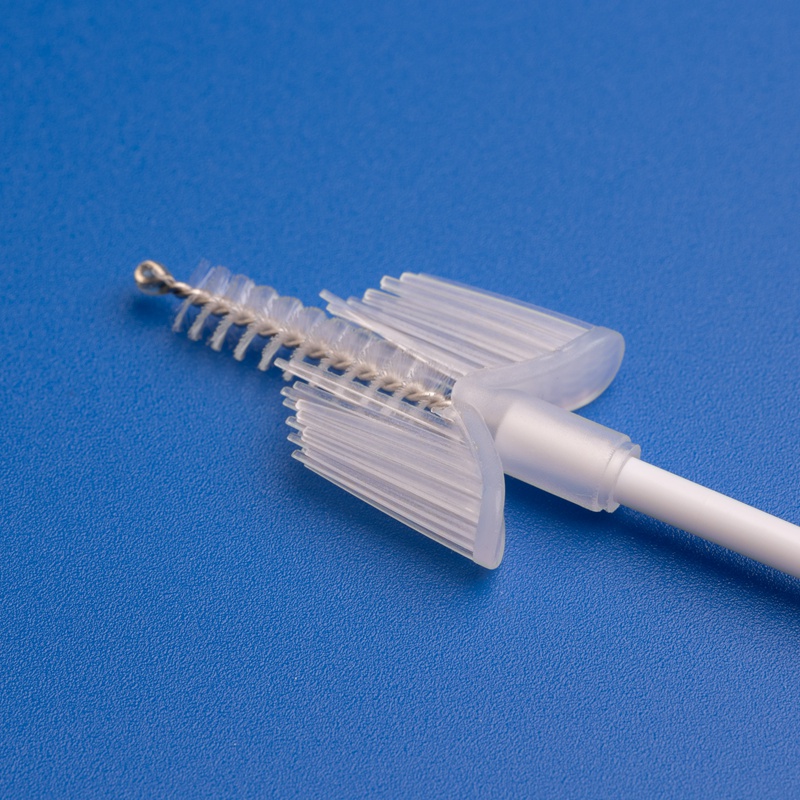

Equipos de flocado automatizados

Utiliza tecnología de flocado electrostático para distribuir uniformemente las fibras en las puntas de los hisopos, lo que mejora la retención de la muestra y la eficiencia de liberación.

Ensamblaje y embalaje inteligentes

Las líneas de montaje robóticas de alta velocidad reducen los riesgos de contaminación, al tiempo que mantienen la consistencia.

Cámaras de esterilización EO

Equipadas con unidades de esterilización EO de control de precisión, que garantizan la eliminación del 99,99% de bacterias y virus.

Producción en sala blanca de clase 100.000

Mantiene un entorno ultraestéril para evitar la contaminación durante la producción. Los estrictos sistemas de filtración de aire garantizan un entorno controlado que cumple con las normas de fabricación médica.

Procesos innovadores

Cada etapa de nuestro proceso de producción se controla cuidadosamente para mantener la consistencia, la eficiencia y el cumplimiento de las normas médicas internacionales.

01

Selección y pretratamiento de materiales

Obtenemos materias primas de grado médico de alta calidad, inspeccionándolas y tratándolas rigurosamente antes de su procesamiento.

02

Moldeo y fabricación de precisión

El moldeo por inyección avanzado y las técnicas de corte de alta velocidad garantizan unas dimensiones uniformes y durabilidad.

03

Flocado y recubrimiento automatizados

Utilización de tecnología electrostática para la adherencia uniforme de las fibras, lo que mejora la retención de la muestra en los hisopos.

04

Ensamblaje e inspección de calidad

Ensamblaje automatizado en varias etapas, seguido de la supervisión de la calidad en tiempo real y la detección de defectos.

05

Esterilización y embalaje

Esterilización EO y envasado hermético en un entorno de sala blanca controlada para mantener la esterilidad del producto.

Nuestro equipo: Experiencia y dedicación

En Hanheng, nuestro equipo se basa en la experiencia, la precisión y la innovación. Reunimos a profesionales cualificados de producción, investigación y control de calidad, garantizando los más altos estándares en la fabricación de consumibles médicos.

Equipo de producción

Técnicos e ingenieros experimentados supervisan la fabricación automatizada, el moldeo de precisión y la supervisión de procesos en tiempo real, garantizando la eficiencia y la consistencia.

Equipo de I+D

Expertos en ciencia de los materiales e ingeniería biológica se centran en la innovación de productos, el diseño ergonómico y la optimización del rendimiento para satisfacer las necesidades cambiantes de la industria.

Equipo de control de calidad

Los especialistas implementan rigurosas inspecciones y protocolos de pruebas para mantener estrictos estándares internacionales.

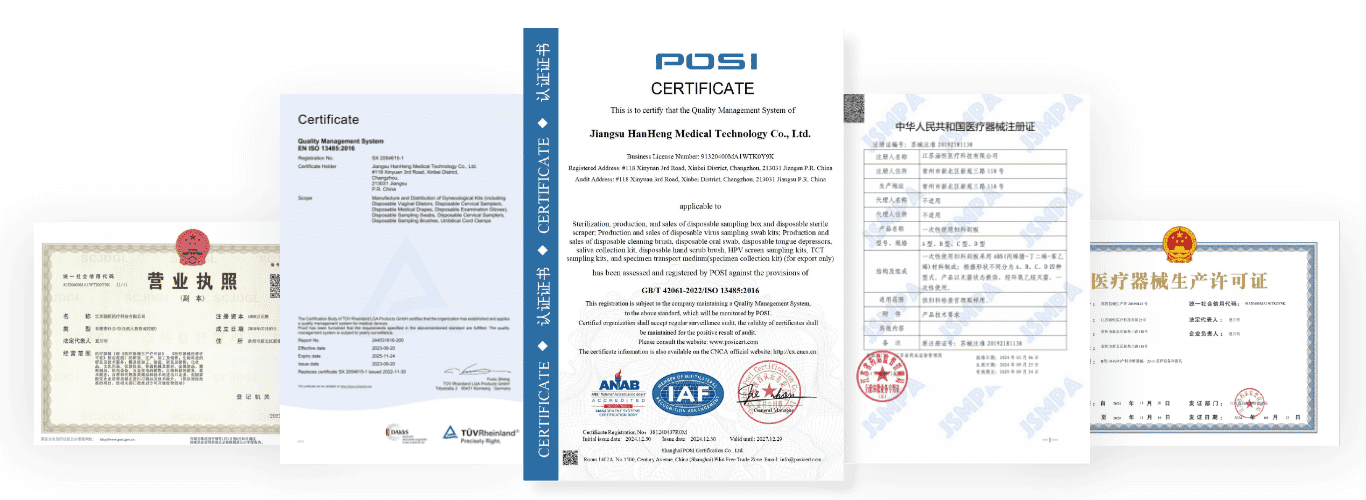

Calidad y cumplimiento líderes en la industria

En Hanheng, nos adherimos a las normas médicas mundiales más estrictas, garantizando que nuestros procesos de fabricación cumplen y superan los puntos de referencia de la industria. Nuestra fábrica opera bajo certificaciones reconocidas internacionalmente

ISO 13485

Garantiza un estricto control de calidad en el diseño, la producción, la distribución y el servicio.

CE

Confirma el cumplimiento de las normas de salud, seguridad y medio ambiente de la AEE.

Cumplimiento de las GMP

Garantiza unas condiciones de fabricación seguras e higiénicas.

Registro de la FDA

Verifica la seguridad y la eficacia de los dispositivos médicos para el mercado estadounidense.

Nuestro sistema de control de calidad en tiempo real supervisa continuamente los parámetros de producción, detectando anomalías y realizando ajustes instantáneos para evitar defectos.