Factory Overview

Precision Manufacturing Factory

At Hanheng, our state-of-the-art manufacturing facility integrates cutting-edge technology, automation, and rigorous quality control to ensure the highest industry standards. From raw material selection to final sterilization and packaging, every step is optimized for efficiency, precision, and reliability.

By integrating cutting-edge automation and digital monitoring, we enhance precision, efficiency, and scalability, ensuring superior-quality medical consumables for healthcare providers worldwide.

Serving the World

120+ countries.

Hanheng boasts a large-scale production capacity, allowing us to meet the demands of global markets efficiently.

ODM&OEM

Support

Hanheng Equipment and Technology

To ensure the highest level of precision and efficiency, our facility is outfitted with a full range of advanced machinery and intelligent manufacturing systems.

Injection Molding Machines

Produces swab handles, tubes, and other medical plastic components with micron-level accuracy.

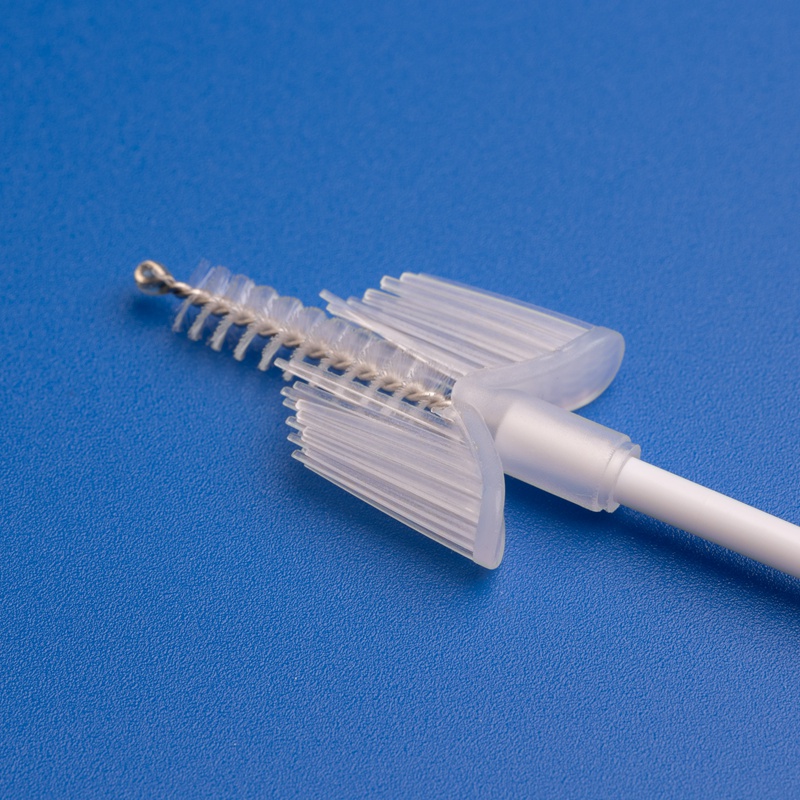

Automated Flocking Equipment

Utilizes electrostatic flocking technology to evenly distribute fibers on swab tips, enhancing sample retention and release efficiency.

Intelligent Assembly & Packaging

High-speed robotic assembly lines reduce contamination risks while maintaining consistency.

EO Sterilization Chambers

Equipped with precision-controlled EO sterilization units, ensuring 99.99% bacterial and viral elimination.

100,000-Class Cleanroom Production

Maintains an ultra-sterile environment to prevent contamination during production. Strict air filtration systems ensure a controlled environment that complies with medical manufacturing regulations.

Innovative Processes

Every stage of our production process is carefully controlled to maintain consistency, efficiency, and compliance with international medical standards.

01

Material Selection & Pre-Treatment

We source high-quality medical-grade raw materials, rigorously inspecting and treating them before processing.

02

Precision Molding & Fabrication

Advanced injection molding and high-speed cutting techniques ensure uniform dimensions and durability.

03

Automated Flocking & Coating

Using electrostatic technology for uniform fiber adherence, improving sample retention in swabs.

04

Assembly & Quality Inspection

Multi-stage automated assembly followed by real-time quality monitoring and defect detection.

05

Sterilization & Packaging

EO sterilization and airtight packaging in a controlled cleanroom environment to maintain product sterility.

Our Team: Expertise & Dedication

At Hanheng, our team is built on expertise, precision, and innovation. We bring together skilled professionals across production, research, and quality control, ensuring the highest standards in medical consumables manufacturing.

Production Team

Experienced technicians and engineers oversee automated manufacturing, precision molding, and real-time process monitoring, ensuring efficiency and consistency.

R&D Team

Experts in materials science and bioengineering focus on product innovation, ergonomic design, and performance optimization to meet evolving industry needs.

Quality Control Team

Specialists implement rigorous inspections and testing protocols to uphold strict international standards.

Industry-Leading Quality & Compliance

At Hanheng, we adhere to the strictest global medical standards, ensuring that our manufacturing processes meet and exceed industry benchmarks. Our factory operates under internationally recognized certifications

ISO 13485

Ensures strict quality control in design, production, distribution, and service.

CE

Confirms compliance with EEA health, safety, and environmental standards.

GMP compliance

Guarantees safe and hygienic manufacturing conditions.

FDA registration

Verifies medical device safety and efficacy for the U.S. market.

Our real-time quality control system continuously monitors production parameters, detecting anomalies and making instant adjustments to prevent defects.